Non-contact wafer transfer equipment

A non-contact, transfer technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as wafer distortion, chipping, etc., to ensure accuracy and efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

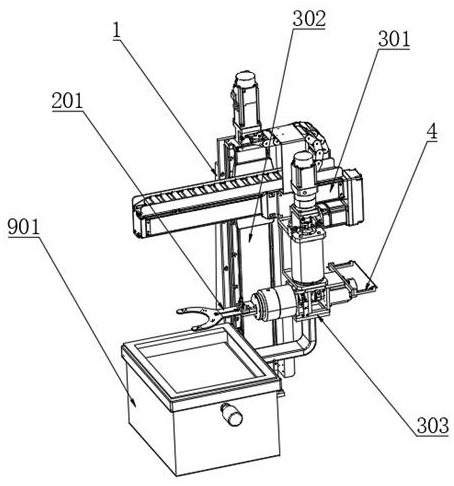

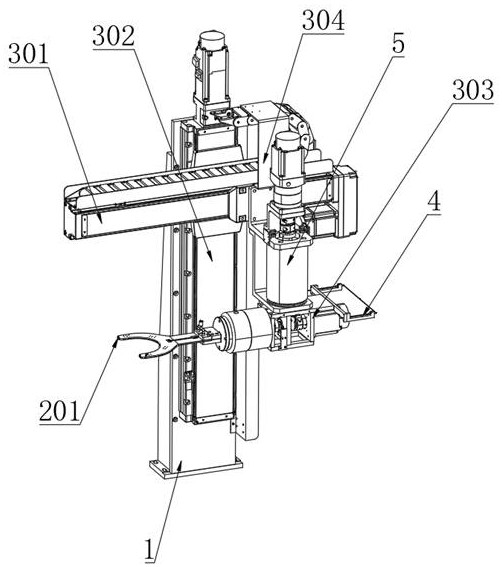

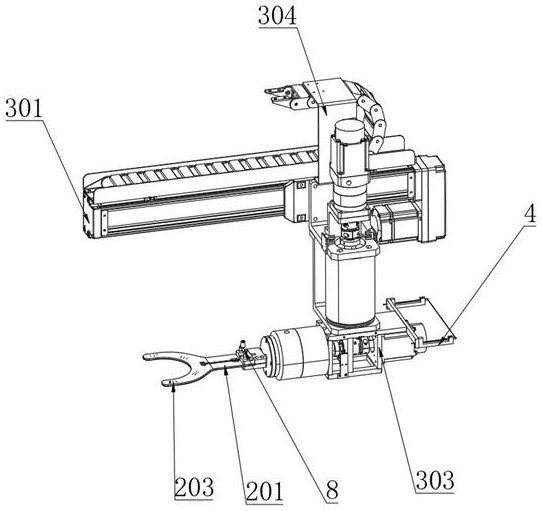

[0036] see Figure 1-10 , a non-contact wafer transfer equipment, including a transfer bracket 1, a suction mechanism 2 is installed on one side of the transfer bracket 1, the suction mechanism 2 includes a Y-shaped gripper 201, and the Y-shaped gripper 201 is installed on the transfer bracket 1. On one side, there are high-pressure air chambers 202 on both sides of the Y-shaped gripper 201, and jet holes 203 are evenly opened on the top of the high-pressure air chamber 202. Inside the jet holes 203, there is a bias flow blocking column 204, and the top side of the bias flow blocking column 204 is installed There is a deflector side plate 205, using the Bernoulli principle, the high-pressure body jet is ejected from the jet hole 203 through the high-pressure air chamber 202, and the jet gas is sprayed laterally around the surface of the Y-shaped claw 201 through the deflection blocking column 204, thereby A cyclone is generated between the surface of the Y-shaped gripper 201 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com