Spring roll ingredients, heat cooking spring roll, and manufacturing method therefor

A technology for stuffing and spring rolls, applied in application, food science, fried food, etc., can solve the problems of reducing quality and stickiness of spring rolls, and achieve the effect of maintaining deliciousness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

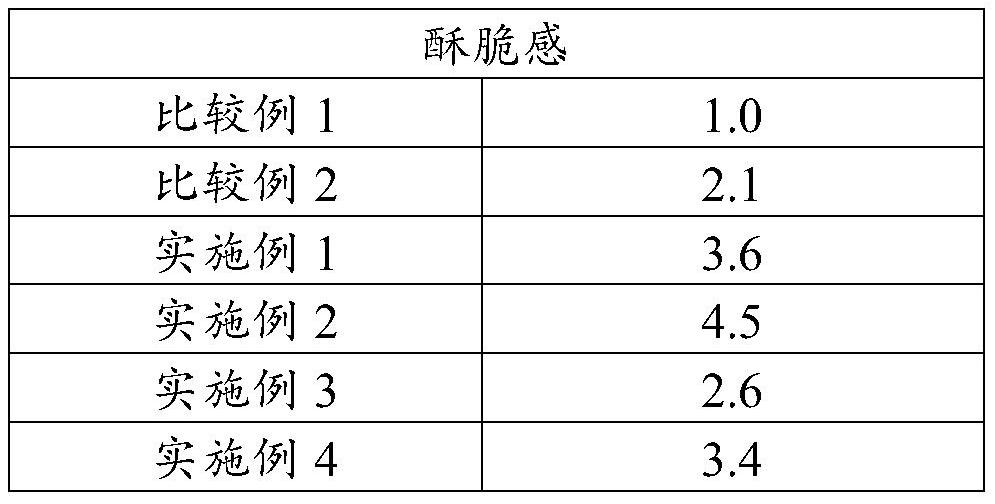

Examples

preparation example Construction

[0077] The method for preparing spring rolls for cooking according to the present invention includes a step of forming a filling, that is, a step of covering at least a part of the surface of the first filling, preferably the entire surface, with the second filling. The first filling can be frozen. The method for preparing spring rolls for cooking according to the present invention may include, after the filling forming step, the step of wrapping the obtained filling in a spring roll wrapper.

[0078] The step of forming the filling in the production method of the present invention is not particularly limited as long as it includes the step of covering at least part of the surface of the first filling with the second filling.

[0079]In the method for preparing spring rolls for heating and cooking of the present invention, the process of wrapping the stuffing in the spring roll leather is the usual molding method, as long as the whole stuffing is covered and wrapped, there is ...

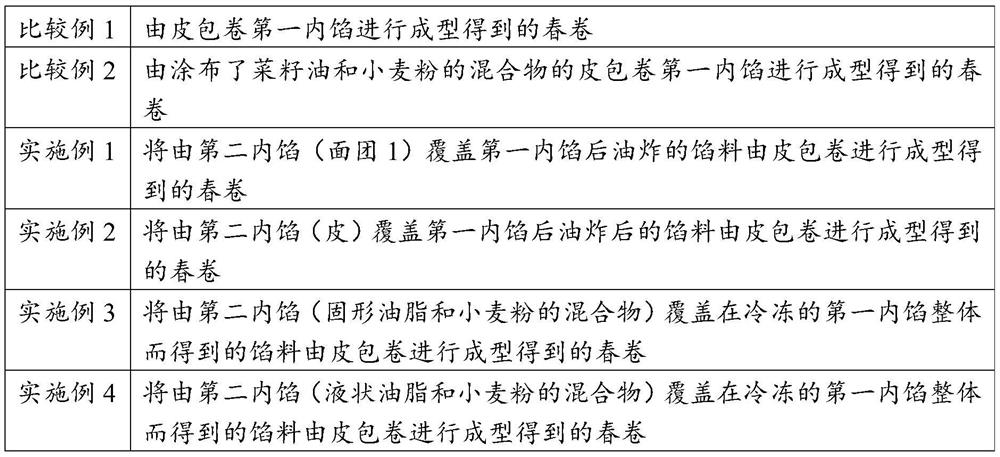

Embodiment

[0087] Hereinafter, although an Example and a comparative example demonstrate this invention more concretely, the technical scope of this invention is not limited to these illustrations. It should be noted that, unless otherwise specified, all percentages and ratios used in the present invention are mass ratios.

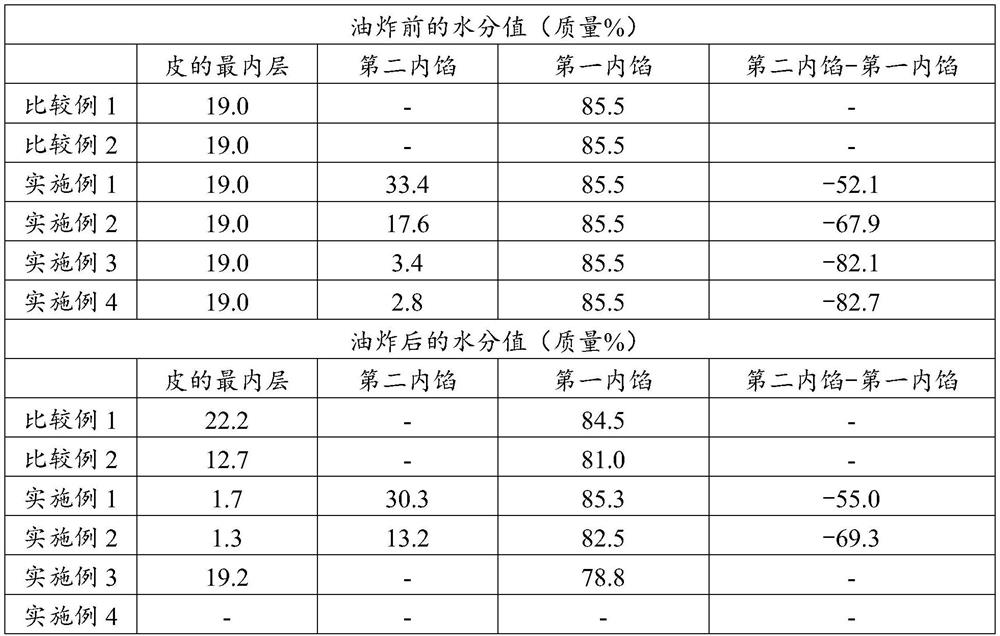

[0088] Method of Determination of Moisture Value

[0089] The measurement of the moisture value was performed using a moisture analyzer (SMART6 (trademark), manufactured by CEM Japan Co., Ltd.).

[0090] Preparation Example 1: The preparation of the first filling

[0091] Prepare as follows: Stir fry 100 grams of pork, 500 grams of boiled bamboo shoots (cut into pieces), 100 grams of leeks (cut into 2 to 3 cm sections), 300 grams of bean sprouts with 3 tablespoons of oil, and then add 2 hours of Spoon of granulated sugar, 1 / 3 tsp of salt, 1 tbsp of soy sauce, 2 tbsp of wine, a little pepper for seasoning, make it viscous by modifying the starch, and use it as the...

Embodiment 1

[0100] Embodiment 1 (an example using dough as the second filling)

[0101] 1) As Dough 1, a dough obtained by kneading 50 parts by mass of low-gluten flour and 20 parts by mass of water with a Kenmix Mixer (Kenmix Aiko Premium, manufactured by Aikosha Seisakusho) was used.

[0102] 2) 15 g of the second filling (dough) prepared above was pressed to 0.4 mm by a noodle machine (Imperial Pasta Machine, manufactured by Imperial).

[0103] 3) Place the first filling (dough) obtained from Preparation Example 1 on the second filling (dough) pressed in 2), cover it completely so that there is no overlap as much as possible, and cut off the excess with scissors.

[0104] 4) Fry the stuffing obtained in 3) in soybean oil at 175° C. for 3 minutes. As a result, the moisture value of dough 1 was 33.4% by mass.

[0105] 5) In the same way as usual spring rolls, place the stuffing obtained in 4) on the skin to form a spring roll. At least a portion of the skin is 7 layers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com