Polyester carbonate resin, and molded body which is obtained by molding resin composition containing said resin

A technology of polyester carbonate and molded body, applied in the direction of instruments, lenses, optical components, etc., can solve the problems of high material cost, poor molding processability, low productivity, etc., achieve high glass transition temperature, reduce photoelastic coefficient, good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

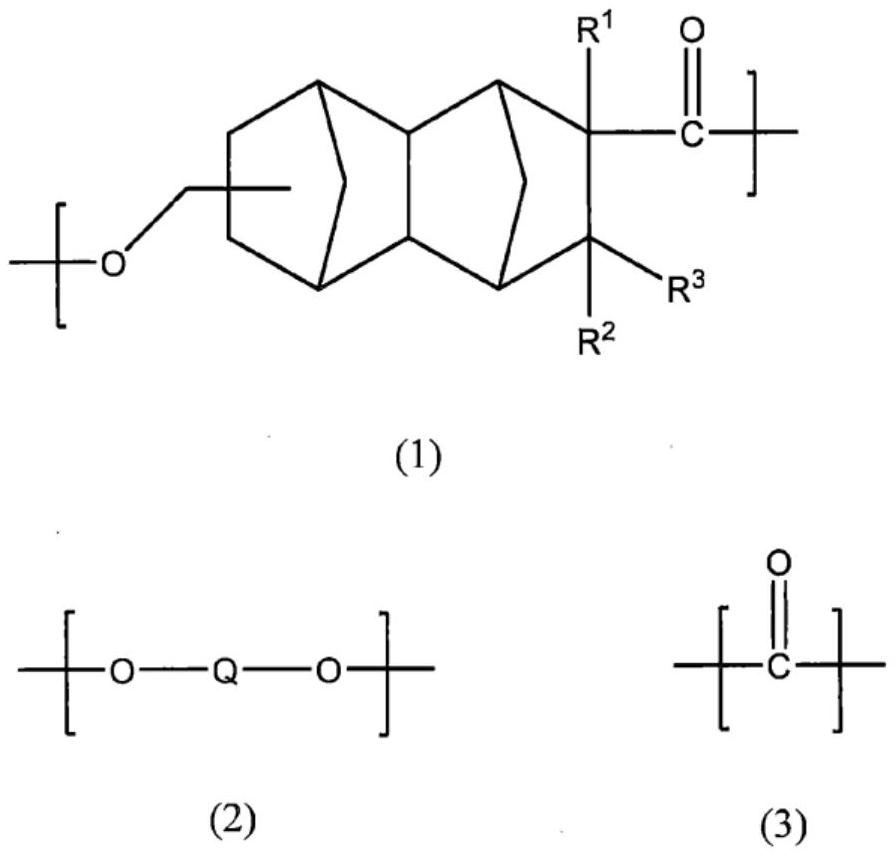

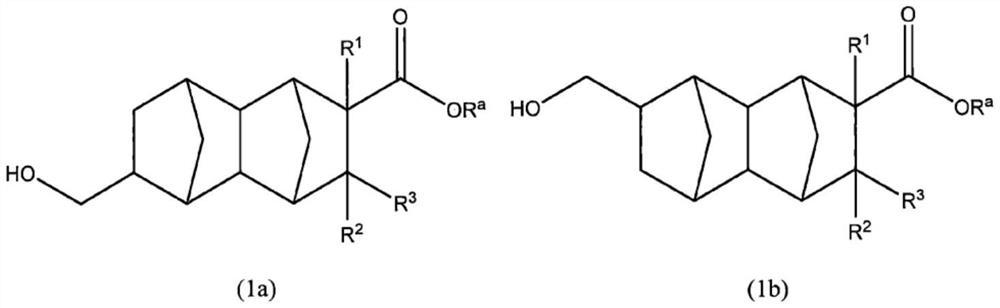

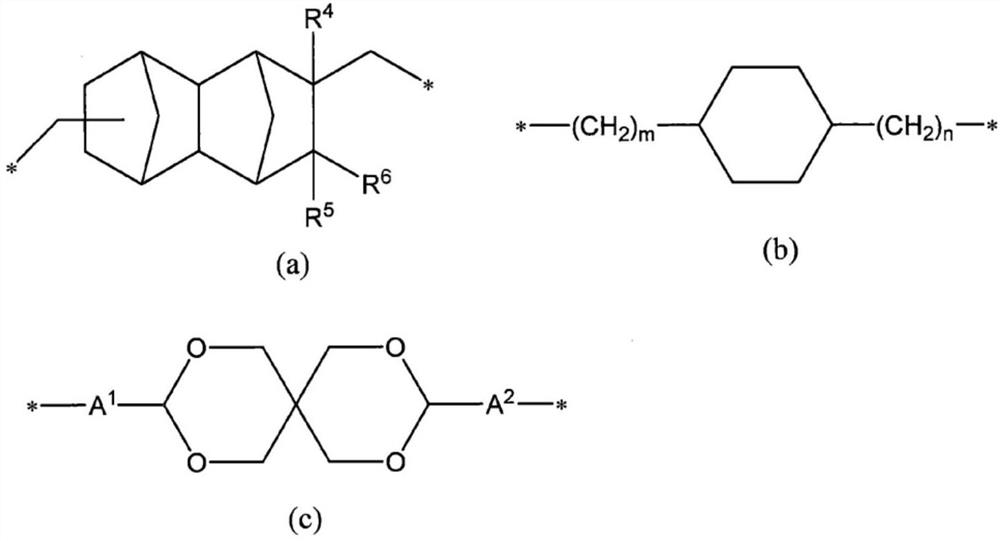

Method used

Image

Examples

Embodiment 1

[0284] D-NHEs: 56.14g (0.224mol), D-NDM: 199.30g (0.896mol), diphenyl carbonate (DPC): 192.24g (0.897mol) and tetrabutoxytitanium: 38.6mg (11.3×10 -5 mol) were added to a 500mL reactor equipped with a stirrer and a distillation device, nitrogen gas was introduced into the system, and heated to 180° C. for 1 hour while stirring under a nitrogen atmosphere of 101.3 kPa. Then, after reaching 180°C, the pressure was reduced to 40kPa over 30 minutes, and the temperature was raised to 255°C over 2 hours from the start of decompression, and when methanol and phenol were distilled out to 60%, the pressure was reduced over 1 hour. Pressure to below 0.133kPa. Thereafter, the temperature was maintained at 0.133 kPa or lower for 30 minutes to obtain a polyester carbonate resin (1).

[0285] The physical properties of this polyester carbonate resin (1) are Mw: 31,000, Tg: 141°C, MVR: 38cm 3 / 10min, refractive index nd: 1.532, specific gravity: 1.19, birefringence: 88nm, photoelastic coef...

Embodiment 2

[0287] D-NHEs: 89.44g (0.357mol), D-NDM: 185.32g (0.834mol), diphenyl carbonate (DPC): 178.75g (0.834mol) and tetrabutoxytitanium: 20.2mg (5.9×10 -5 mol) were added to a 500mL reactor equipped with a stirrer and a distillation device, and the same operation as in Example 1 was performed to obtain a polyester carbonate resin (2).

[0288] The physical properties of this polyester carbonate resin (2) are Mw: 29,000, Tg: 142°C, MVR: 48cm 3 / 10min, refractive index nd: 1.534, specific gravity: 1.19, birefringence: 76nm, photoelastic coefficient: 5×10 -12 Pa -1 .

Embodiment 3

[0290] D-NHEs: 154.68g (0.618mol), D-NDM: 137.36g (0.618mol), diphenyl carbonate (DPC): 134.34g (0.627mol) and tetrabutoxytitanium: 20.5mg (6.0×10 -5 mol) were respectively added to a 500mL reactor equipped with a stirrer and a distillation device, and the same operation as in Example 1 was performed to obtain a polyester carbonate resin (3).

[0291] The physical properties of this polyester carbonate resin (3) are Mw: 29,000, Tg: 145°C, MVR: 52cm 3 / 10min, refractive index nd: 1.535, specific gravity: 1.18, birefringence: 65nm, photoelastic coefficient: 4×10 -12 Pa -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| photoelasticity | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap