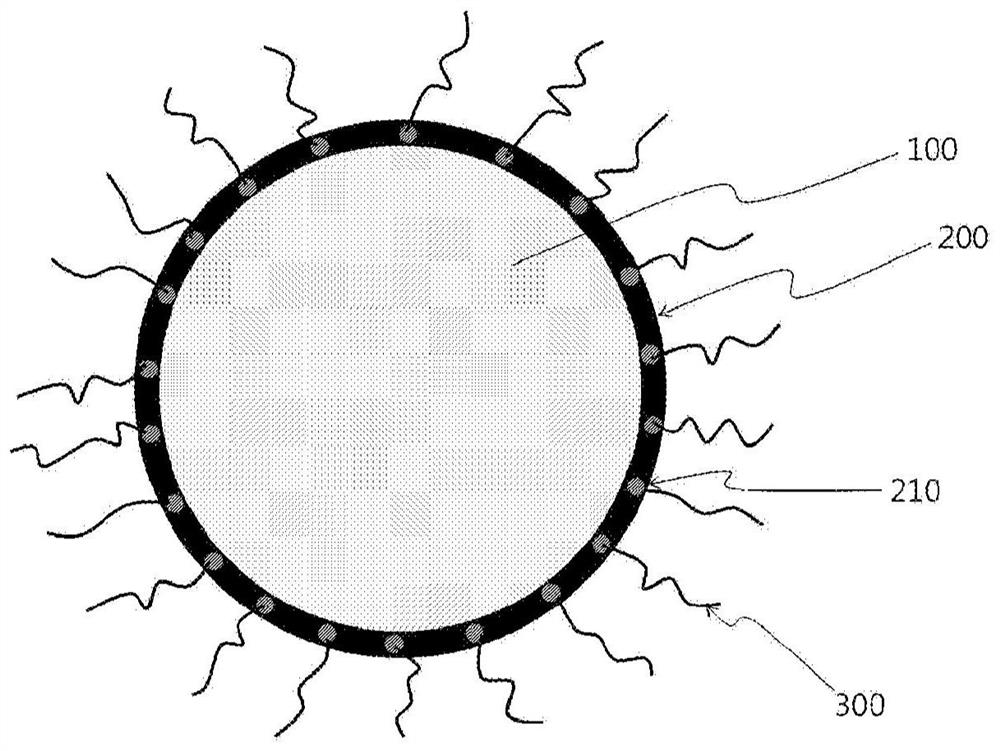

Anode active material and manufacturing method therefor

A negative electrode active material, negative electrode technology, applied in the field of negative electrode active material and its preparation, can solve problems such as reducing efficiency, and achieve the effect of excellent electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0069]In the method for preparing an anode active material according to the present invention, the preparing a mixture including the transition metal compound and the carbon source may include dispersing or dissolving the transition metal compound in the carbon source (ie, an alcohol-based solvent).

[0070] The content of the transition compound may be 0.01% to 10% by weight, specifically 0.05% to 5% by weight, more specifically 0.1% to 3% by weight, based on the entire mixture. When the content of the transition metal compound is within the above range, the carbon coating can be made to satisfy the above content and thickness, and the carbon nanotubes can be made to satisfy the above content and thickness, so that the carbon coating can more effectively reduce the amount of silicon species The volume of the particles varies, and the carbon nanotubes can provide a sufficient electrical contact path while properly maintaining the conductivity of the negative electrode, whereby ...

Embodiment approach

[0099] According to another exemplary embodiment of the present invention, there are provided: a battery module including the secondary battery as a unit cell; and a battery pack including the battery module. Since the battery module and the battery pack include the secondary battery having high capacity, high rate performance, and cycle characteristics, the battery module and the battery pack can be used as a power source for medium to large-scale devices selected from the group consisting of: electric vehicles, hybrids electric vehicles, plug-in hybrid electric vehicles; and power storage systems.

Embodiment 1

[0103] The Si and SiO 2 The powders mixed in a molar ratio of 1:1 were heated under vacuum at 1400°C to form SiO vapor. In addition, Mg was vacuum heated at 700°C to form Mg vapor.

[0104] SiO vapor and Mg vapor were mixed in a weight ratio of 95:5 and reacted with each other in a cooling zone at 500 °C to prepare solid-phase condensed Mg-SiO, which was then ground using a ball mill to prepare a 5 μm size Powder (silicon-based particles).

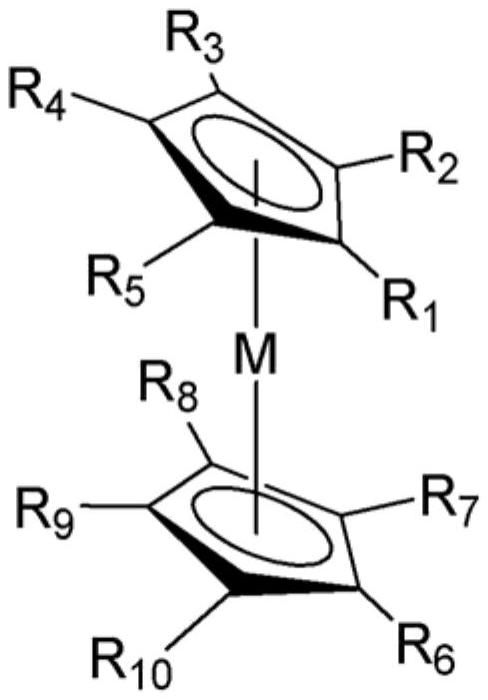

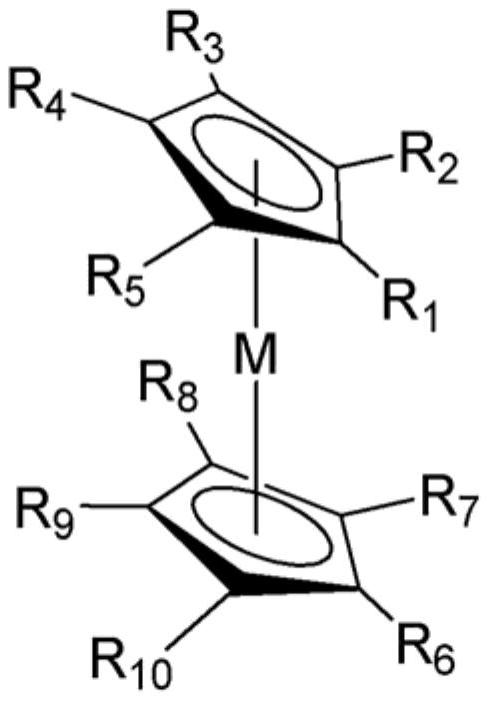

[0105] will correspond to the η of the metallocene catalyst 5 -(C 5 H 5 ) 2 Fe was mixed with ethanol and used a mist generator (17Mhz, and 30W conditions) to make 1 wt% η 5 -(C 5 H 5 ) 2 Fe fog.

[0106] While maintaining an inert gas atmosphere by flowing Ar gas, Mg—SiO powder was placed in the hot zone of the CVD apparatus, and the mist was blown into the hot zone at 1000° C. using Ar as a carrier gas. The reaction was performed for 30 seconds, thereby preparing a negative electrode active material in which a carbon coating l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com