A kind of carbon black and its preparation method and application

A technology of carbon black and oxidized carbon black, which is applied in the direction of fibrous fillers, shielding materials, electrical components, etc., can solve problems such as difficulty in producing high-quality carbon black products, and achieve high oil absorption value, improved electrical conductivity, and good stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

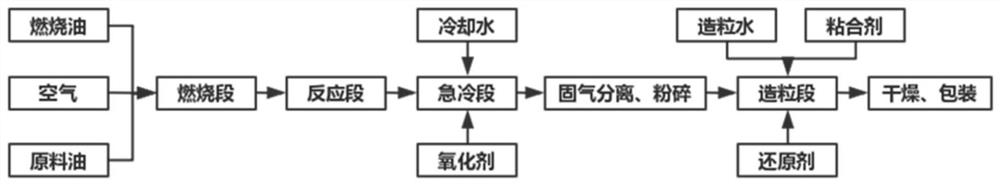

[0047]The present embodiment has prepared a kind of carbon black, and its process schematic diagram is as follows figure 1 As shown, the specific process is:

[0048] S1: Add coal tar and air preheated to 100°C to the combustion section of the reaction furnace at a mass flow ratio of 60:1, and the coal tar and air are burned in the combustion section;

[0049] S2: Add raw material oil to the reaction section of the reaction furnace, set the reaction temperature to 1850°C to 1900°C, and the pressure to 0.5MPa. When the raw material oil undergoes cracking reaction and gradually forms aggregates, spray cooling water at a rate of 5kg / h , cool the carbon black flue gas, terminate the carbon black reaction, and add a mass concentration of 1kg / m in the cooling water at the same time 3 Potassium permanganate is used to catalyze and activate carbon black aggregates to obtain carbon black flue gas with developed pore structure;

[0050] S3: Set the pressure of the air delivery pipe in...

Embodiment 2

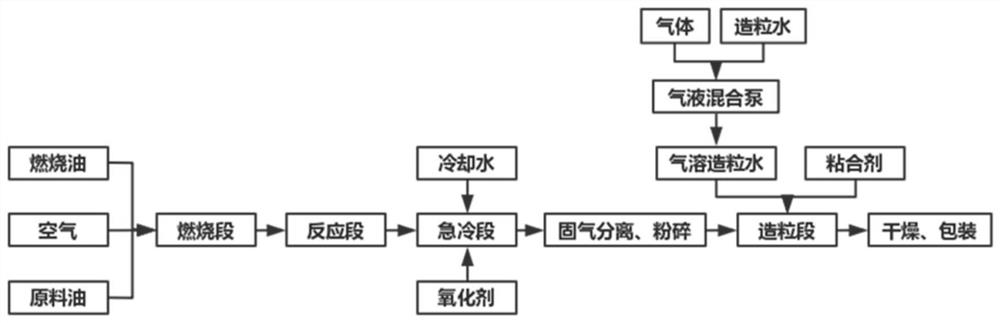

[0054] The present embodiment has prepared a kind of carbon black, and its process schematic diagram is as follows figure 2 As shown, the specific process is:

[0055] S1: Add coal tar and air preheated to 110°C to the combustion section of the reaction furnace at a mass flow ratio of 65:1, and the coal tar and air are burned in the combustion section;

[0056] S2: Add raw material oil to the reaction section of the reaction furnace, set the reaction temperature at 1850°C to 1900°C, and the pressure at 0.6MPa. When the raw oil undergoes cracking reaction and gradually forms aggregates, spray cooling water at a flow rate of 7kg / h , cool the carbon black flue gas, terminate the carbon black reaction, and add the mass concentration of 1.2kg / m in the cooling water at the same time 3 The dilute nitric acid is used to catalyze and activate carbon black aggregates to obtain carbon black flue gas with developed pore structure;

[0057] S3: Set the pressure of the air delivery pipe ...

Embodiment 3

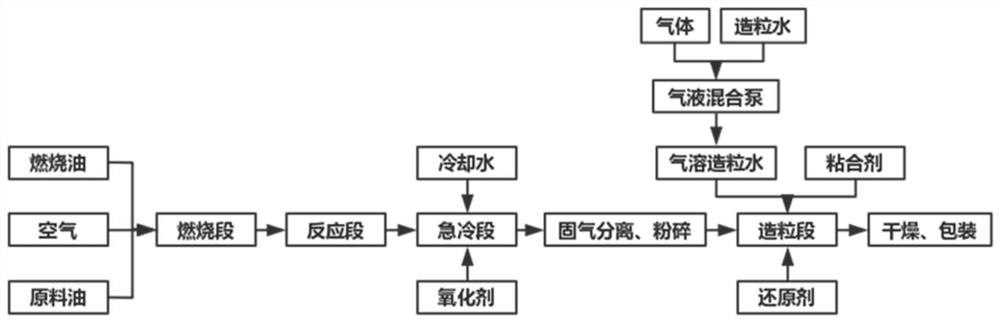

[0061] The present embodiment has prepared a kind of carbon black, and its process schematic diagram is as follows image 3 As shown, the specific process is:

[0062] S1: Add coal tar and air preheated to 120°C to the combustion section of the reaction furnace at a mass flow ratio of 70:1, and the coal tar and air are burned in the combustion section;

[0063] S2: Add raw material oil to the reaction section of the reaction furnace, set the reaction temperature to 1850°C to 1900°C, and the pressure to 0.5MPa. When the raw material oil undergoes cracking reaction and gradually forms aggregates, spray cooling water at a flow rate of 9kg / h , cool the carbon black flue gas, terminate the carbon black reaction, and add a mass concentration of 1.5kg / m in the cooling water at the same time 3 Iodine, catalytic activation of carbon black aggregates, to obtain carbon black flue gas with well-developed pore structure;

[0064] S3: Set the pressure of the air delivery pipe in the air s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com