Preparation method of composite electroconductive plastic

A conductive plastic and composite technology, applied in the plastic industry, can solve problems such as poor mechanical properties, and achieve the effects of improving mechanical strength, enhancing electrical conductivity, and improving electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

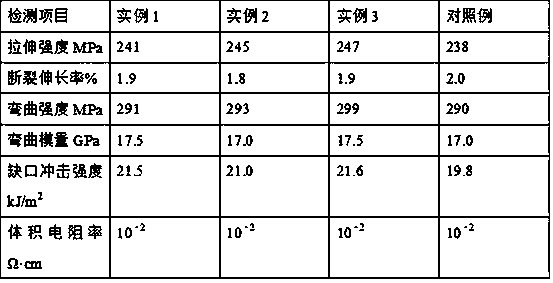

Examples

Example Embodiment

[0027] Example 1

[0028] In parts by weight, take 1 part of gum arabic, 8 parts of green bamboo and 0.5 part of 200 mesh copper powder, put the green bamboo, gum arabic and copper powder together in a ball milling tank, ball mill at 200r / min for 2h to obtain colloid Powder mixture; fill the prepared colloidal powder mixture into a block mold, press it at 5MPa at room temperature, hold the pressure for 2 minutes, demold and place it in an oven at 80°C, after heat curing for 1 hour, stand and cool to The solidified material is obtained at room temperature; the solidified material is placed in a tubular atmosphere furnace, nitrogen is introduced, the flow of nitrogen is controlled to be 45mL / min, the temperature is controlled at 600 ℃ in a nitrogen atmosphere, and the temperature is kept for 2 hours to obtain a carbonized mixture; The mixture is placed in a ball milling tank, ball milled at a speed of 300r / min for 3 hours and passed through a 300 mesh sieve to obtain carbonized par...

Example Embodiment

[0029] Example 2

[0030] In parts by weight, take 2 parts of gum arabic, 9 parts of green bamboo and 1.0 part of 200 mesh copper powder, put the green bamboo, gum arabic and copper powder together in a ball milling tank, ball mill at 220r / min for 2h to obtain colloid Powder mixture; fill the prepared colloidal powder mixture into a block mold, press it at 8MPa at room temperature, hold the pressure for 2 minutes, demold and place it in an oven at 90°C, after heat curing for 1 hour, stand and cool to At room temperature, the solidified material is obtained; the solidified material is placed in a tubular atmosphere furnace, nitrogen is introduced, the flow of nitrogen is controlled to 48mL / min, the temperature is controlled at 650℃ in a nitrogen atmosphere, and the temperature is kept for 2 hours to obtain a carbonized mixture; The mixture is placed in a ball milling tank, ball milled at a speed of 350r / min for 3 hours and passed through a 300 mesh sieve to obtain carbonized parti...

Example Embodiment

[0031] Example 3

[0032] In parts by weight, take 3 parts of gum arabic, 10 parts of green bamboo and 1.5 parts of 200 mesh copper powder, put the green bamboo, gum arabic and copper powder together in a ball milling tank, ball mill at 250r / min for 3 hours to obtain colloid Powder mixture; fill the prepared colloidal powder mixture into a block mold, press it at 10MPa at room temperature, hold the pressure for 3 minutes, demold and place it in an oven at 100°C, after heat curing for 2 hours, stand and cool to The solidified material is obtained at room temperature; the solidified material is placed in a tubular atmosphere furnace, nitrogen is introduced, the flow of nitrogen is controlled to 50mL / min, the temperature is controlled at 700 ℃ in a nitrogen atmosphere, and the temperature is kept for 3 hours to obtain a carbonized mixture; The mixture is placed in a ball mill tank, ball milled at a speed of 400r / min for 4 hours, and passed through a 300 mesh sieve to obtain carboniz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com