Device for measuring hydration heat radiation velocity and hydration period of cement and use method of device

A heat release rate and cement hydration technology, which is applied to the device for measuring the heat release rate and hydration period of cement hydration, and in the field of cement concrete performance testing, can solve the problems of complex preparation, short continuous monitoring time, complicated operation, etc., and achieve The technical and economic benefits are obvious, the experimental equipment is portable, and the effect of avoiding particle stratification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

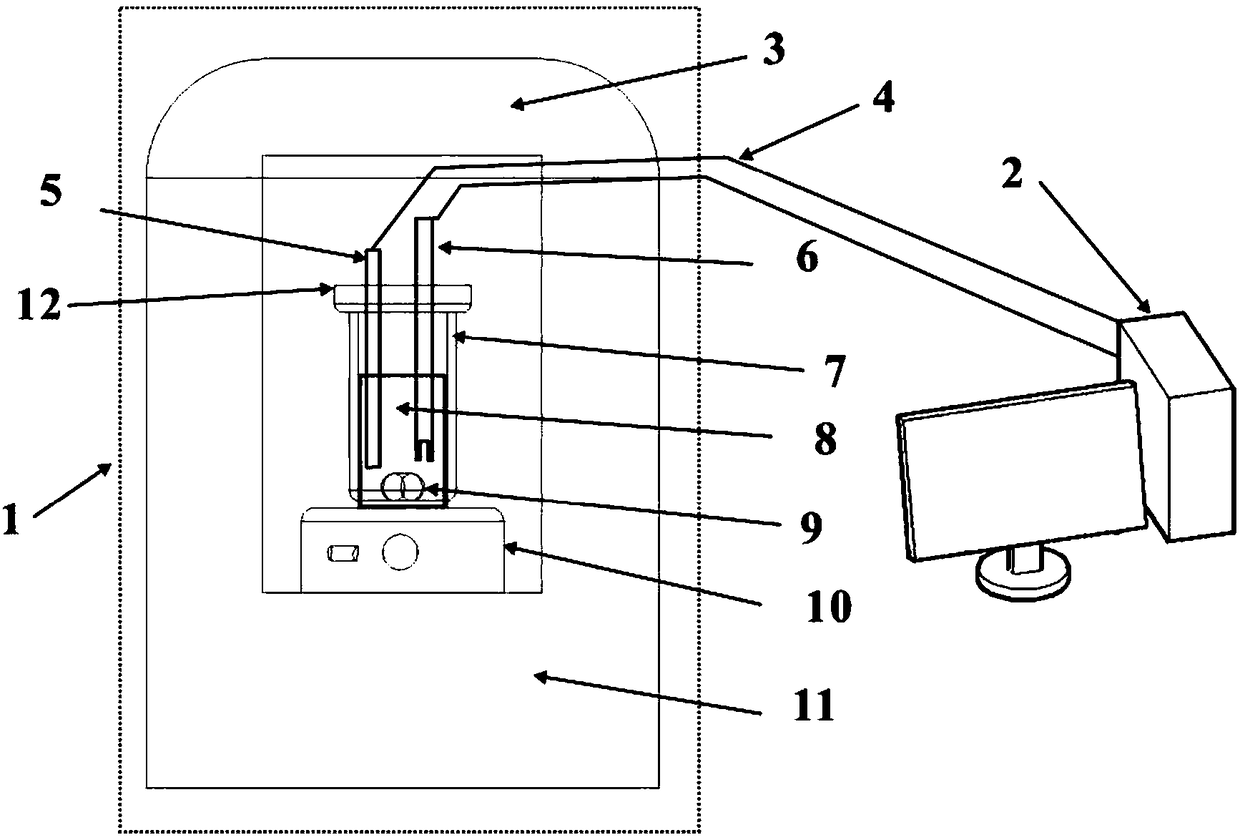

[0039] A device for measuring cement hydration heat release rate and hydration period, the device is composed of a test device 1 and a computer 2;

[0040] Wherein the testing device 1 comprises a heat preservation chamber 11 and a heat preservation chamber cover 3, both of which constitute a sealed environment, a sample chamber 7 is arranged inside the heat preservation chamber 11, an electromagnetic stirring device 10 and a sample pool 8 are arranged inside the sample chamber 7, and the electromagnetic stirring device 10 is located at the bottom of the inside of the sample chamber 7, the sample cell 8 is placed on the electromagnetic stirring device 10, and the upper opening of the sample cell 8 is sealed by a sealing cover 12, and the temperature sensor 5 and the conductivity sensor 6 are arranged through the sealing cover 12 , one end of the test point extends into the sample pool 8, the other end is respectively connected with a data line 4, and a stirring rotor 9 is place...

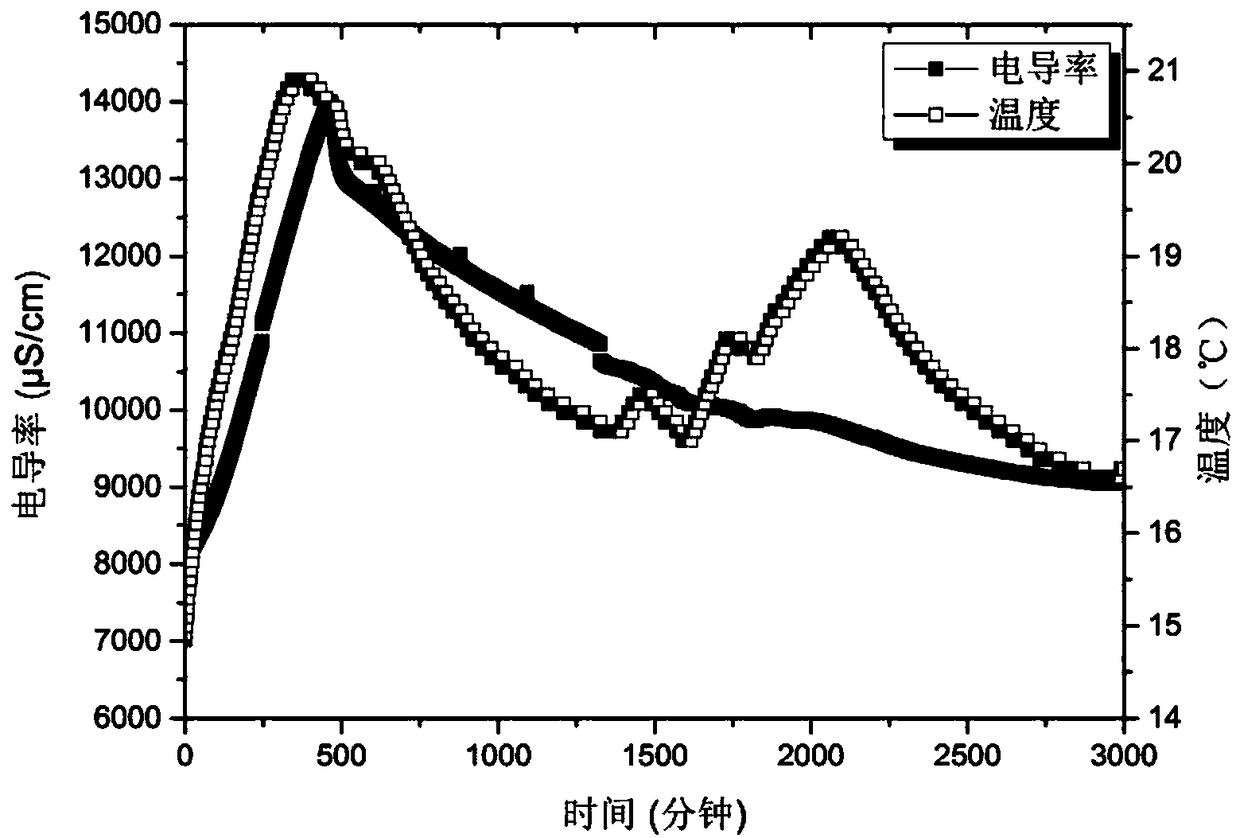

Embodiment 2

[0049] A device for measuring cement hydration heat release rate and hydration period, the device is composed of a test device 1 and a computer 2;

[0050] Wherein the testing device 1 comprises a heat preservation chamber 11 and a heat preservation chamber cover 3, both of which constitute a sealed environment, a sample chamber 7 is arranged inside the heat preservation chamber 11, an electromagnetic stirring device 10 and a sample pool 8 are arranged inside the sample chamber 7, and the electromagnetic stirring device 10 is located at the bottom of the inside of the sample chamber 7, the sample cell 8 is placed on the electromagnetic stirring device 10, and the upper opening of the sample cell 8 is sealed by a sealing cover 12, and the temperature sensor 5 and the conductivity sensor 6 are arranged through the sealing cover 12 , one end of the test point extends into the sample pool 8, the other end is respectively connected with a data line 4, and a stirring rotor 9 is place...

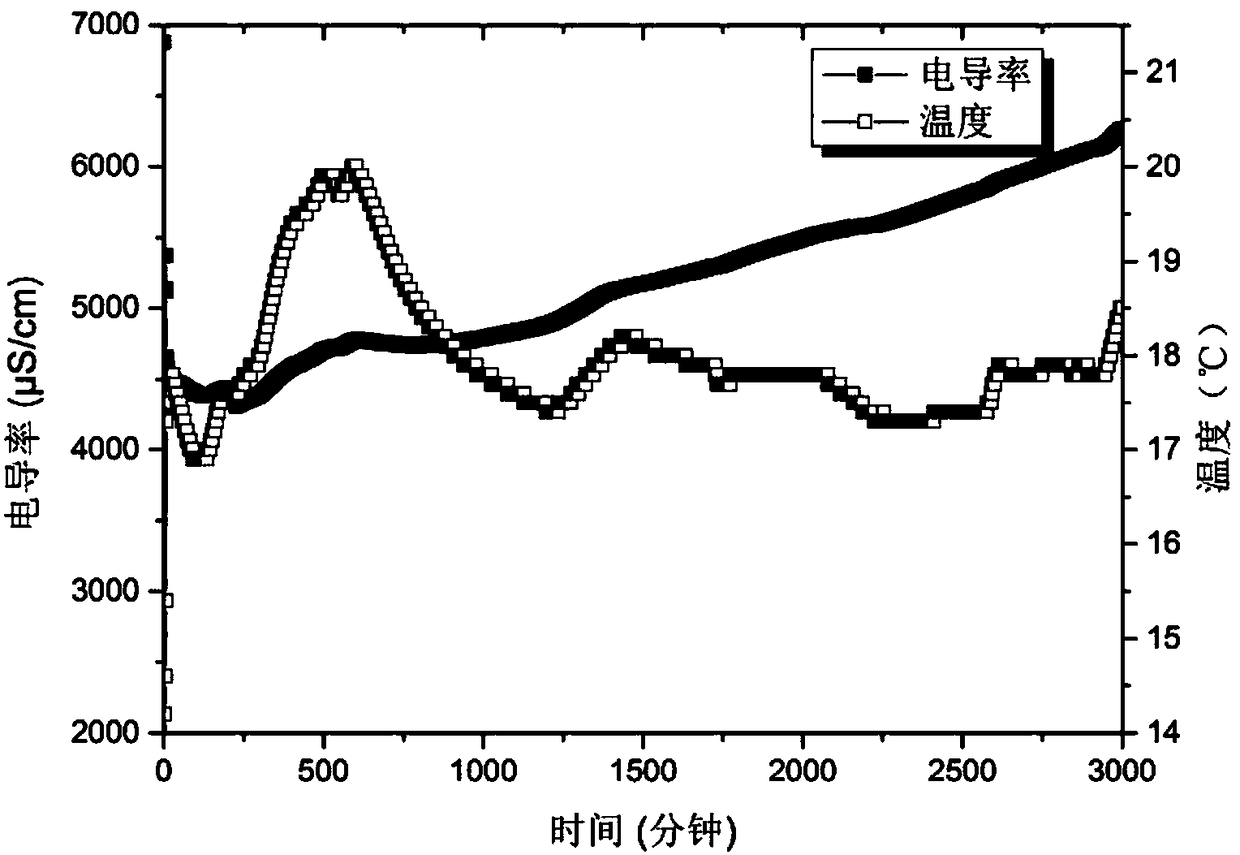

Embodiment 3

[0059] A device for measuring cement hydration heat release rate and hydration period, the device is composed of a test device 1 and a computer 2;

[0060] Wherein the testing device 1 comprises a heat preservation chamber 11 and a heat preservation chamber cover 3, both of which constitute a sealed environment, a sample chamber 7 is arranged inside the heat preservation chamber 11, an electromagnetic stirring device 10 and a sample pool 8 are arranged inside the sample chamber 7, and the electromagnetic stirring device 10 is located at the bottom of the inside of the sample chamber 7, the sample cell 8 is placed on the electromagnetic stirring device 10, and the upper opening of the sample cell 8 is sealed by a sealing cover 12, and the temperature sensor 5 and the conductivity sensor 6 are arranged through the sealing cover 12 , one end of the test point extends into the sample pool 8, the other end is respectively connected with a data line 4, and a stirring rotor 9 is place...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com