In-situ monitoring device and method of cement concrete structure forming process

A technology of cement concrete and monitoring device, which is applied in the directions of ultrasonic/sonic/infrasonic generation, etc., can solve the problems of lack of research on the structure formation process, and achieve the effect of ensuring direct and close contact, accurate test results, and obvious technical and economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

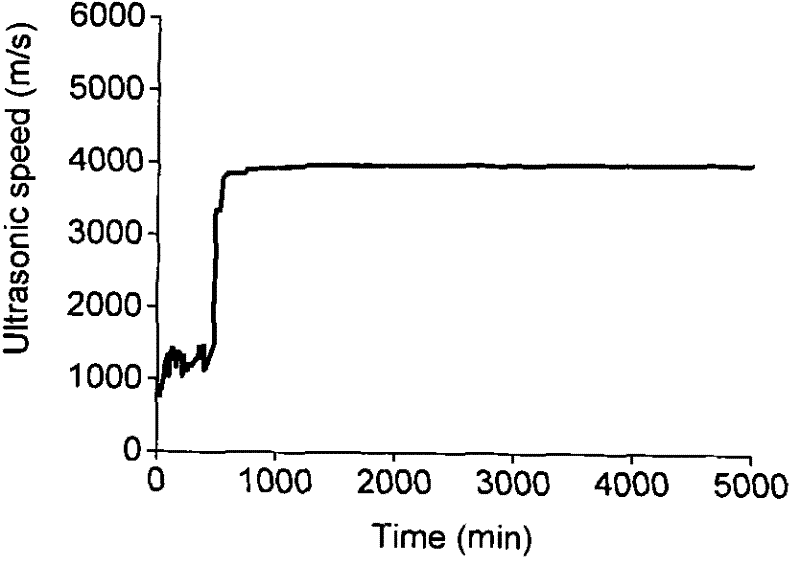

[0030] Use P.II42.5 Portland cement, polycarboxylate superplasticizer with a solid content of 30%, and tap water. Mixing ratio (g): cement-1300, water-208, admixture-32.5

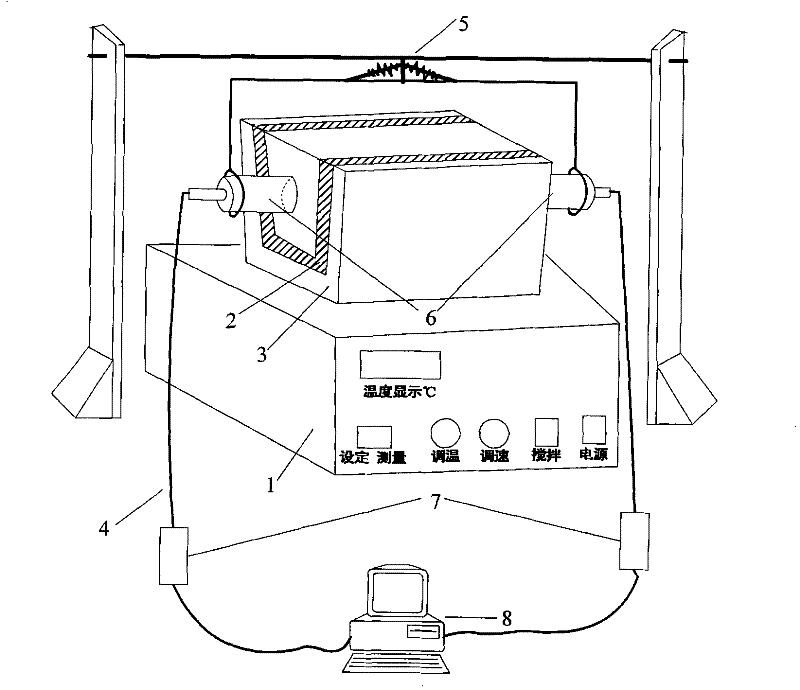

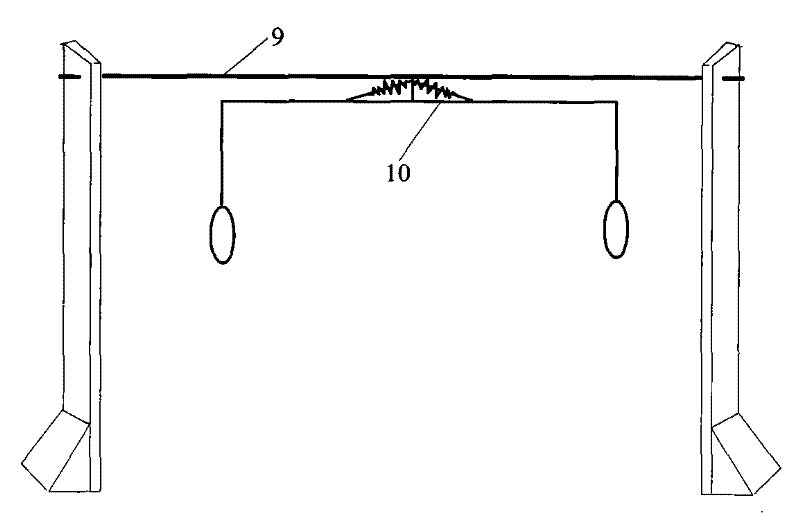

[0031] First fill the oil bath with heat-resistant oil, then place the oil bath on the electromagnetic stirring device, put the magnetic stirrer and temperature sensor in the electromagnetic stirring device into the oil bath, turn on the power of the electromagnetic stirring device, set the temperature and stirrer speed, heat the heat-resistant oil until it reaches 90°C; according to the above ratio, use a forced mixer to mix well, put the freshly mixed cement concrete into the sample chamber quickly, and then insert the sample chamber with the slurry In the oil bath filled with heat-resistant oil, the two piezoelectric sensors of the ultrasonic instrument are finally clamped by the ultrasonic clamping instrument, so that they are in direct and close contact with the cement slurry in the sample chamber, and...

Embodiment 2

[0033] Use P.II42.5 Portland cement, polycarboxylate high-efficiency superplasticizer with a solid content of 30%, Class I fly ash, Elkem silica fume, S95 finely ground slag, and tap water. Mixing ratio (g): cement-650, silica fume-130, fly ash-130, slag-390, water-208, admixture-32.5

[0034]According to the above ratio, after using the forced mixer to mix well, pour the fresh concrete into the dumbbell-shaped inner mold. First, fill the oil bath with heat-resistant oil, then place the oil bath on the electromagnetic stirring device, and turn the electromagnetic Put the magnetic stirrer and temperature sensor in the stirring device into the oil bath, turn on the power of the electromagnetic stirring device, set the temperature and the speed of the stirrer, and heat the heat-resistant oil until it reaches 90°C; according to the above ratio, use a forced mixer to mix well , quickly put the freshly mixed cement concrete into the sample chamber, and then embed the sample chamber ...

Embodiment 4

[0039] Use P.II42.5 Portland cement, polycarboxylate high-efficiency superplasticizer with a solid content of 30%, Class I fly ash, Elkem silica fume, S95 finely ground slag, and tap water. Mixing ratio (g): cement-217, silica fume-43, fly ash-43, slag-130, sand-433, stone-433, water-70, admixture-16.3

[0040] According to the above ratio, after using the forced mixer to mix well, pour the fresh concrete into the dumbbell-shaped inner mold. First, fill the oil bath with heat-resistant oil, then place the oil bath on the electromagnetic stirring device, and turn the electromagnetic Put the magnetic stirrer and temperature sensor in the stirring device into the oil bath, turn on the power of the electromagnetic stirring device, set the temperature and the speed of the stirrer, and heat the heat-resistant oil until it reaches 90°C; according to the above ratio, use a forced mixer to mix well , quickly put the freshly mixed cement concrete into the sample chamber, and then embed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com