A method of making egg rolls

A production method and technology of egg rolls, which are applied in the direction of baking pancakes, food ovens, baking, etc., can solve the problems of reducing the efficiency of egg roll processing and the inability to cut egg roll skins, and achieve the goal of improving efficiency and improving adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

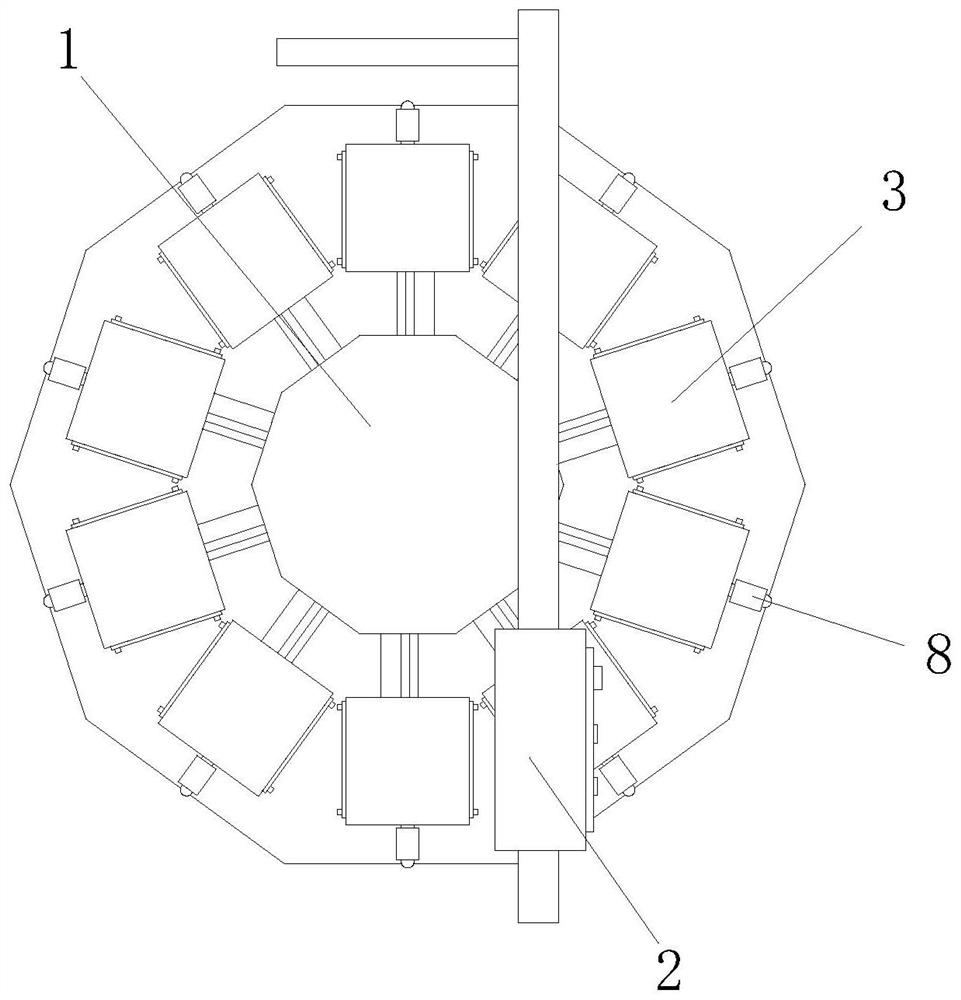

[0033] see Figure 1-7 As shown, a method for making egg rolls, the making method comprises the following steps:

[0034] S1: Start the device through the control panel 2, so that the device main body 1 injects the pre-adjusted batter into the mold chamber 4, so that the batter is dispersed on the surface of the mold plate 6;

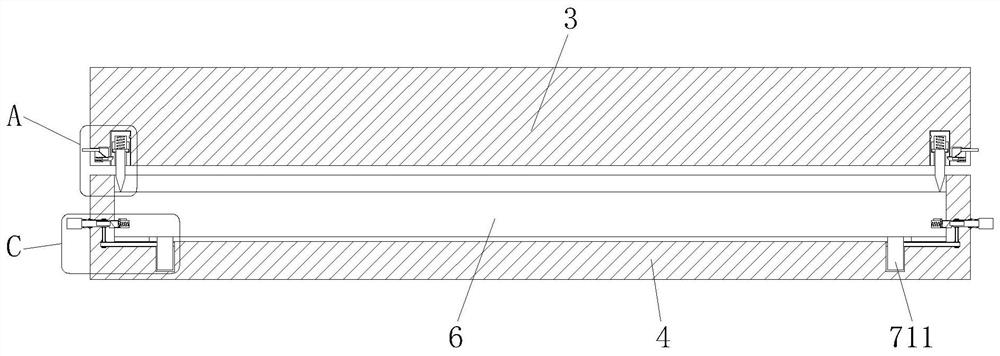

[0035] S2: heating the mold plate 6 through the program-controlled mold chamber 4 to form the batter into a semi-shaped egg roll skin;

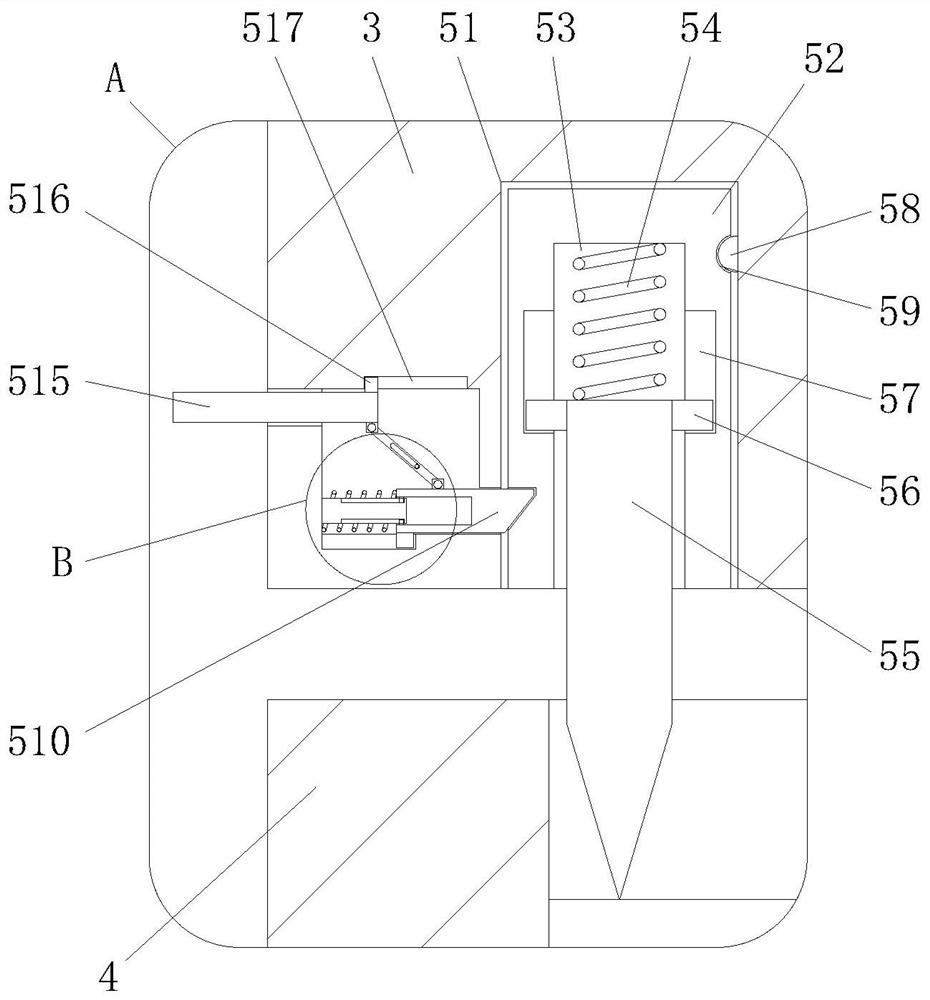

[0036] S3: Drive the cover 3 to open by pulling the handle 8, and then adjust the position of the egg roll skin and press the handle 8 downwards so that the cutting mechanism provided on the cover plate 3 also moves accordingly. cut;

[0037] S4: Continue to heat the cut egg roll skin through the mold chamber 4 and roll the egg roll skin, so that the egg roll skin is completely shaped;

[0038] The egg roll forming includes a device main body 1, a control panel 2, a cover plate 3, a mold chamber 4, a mold plate 6 an...

Embodiment 2

[0054] see Figure 8 As shown in the comparison example 1, as another embodiment of the present invention, the outer side of the screw sleeve 78 is sleeved with a threaded belt 712, and the threaded belt 712 is fixedly connected with the outer wall of the mold chamber 4, and the threaded belt 712 A nut 713 is threadedly connected to the outer side of the threaded nut 713; during operation, the threaded belt 712 is tightly fitted with the outer side of the threaded sleeve 78 by rotating the nut 713 to limit the rotation of the threaded sleeve 78. When the threaded sleeve 78 needs to be rotated When the nut 713 is reversely rotated, the threaded belt 712 can be released from the state in which it is in close contact with the outer side of the screw sleeve 78 .

[0055] Working principle: When cutting the semi-shaped egg roll skin, first pull the handle 8 to drive the cover plate 3 to rotate, and then press the handle 8 downwards, so that the knife body 55 arranged on the cover p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com