Double-disc pelletizer for manufacturing double-layer pellets and method for controlling granularity of pellets by using double-disc pelletizer

A technology of pelletizing machine and double discs, which is applied in the direction of program control, program control, general control system, etc. in the sequence/logic controller, can solve the problem that the pelletizing machine cannot be used to produce double-layer pellets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

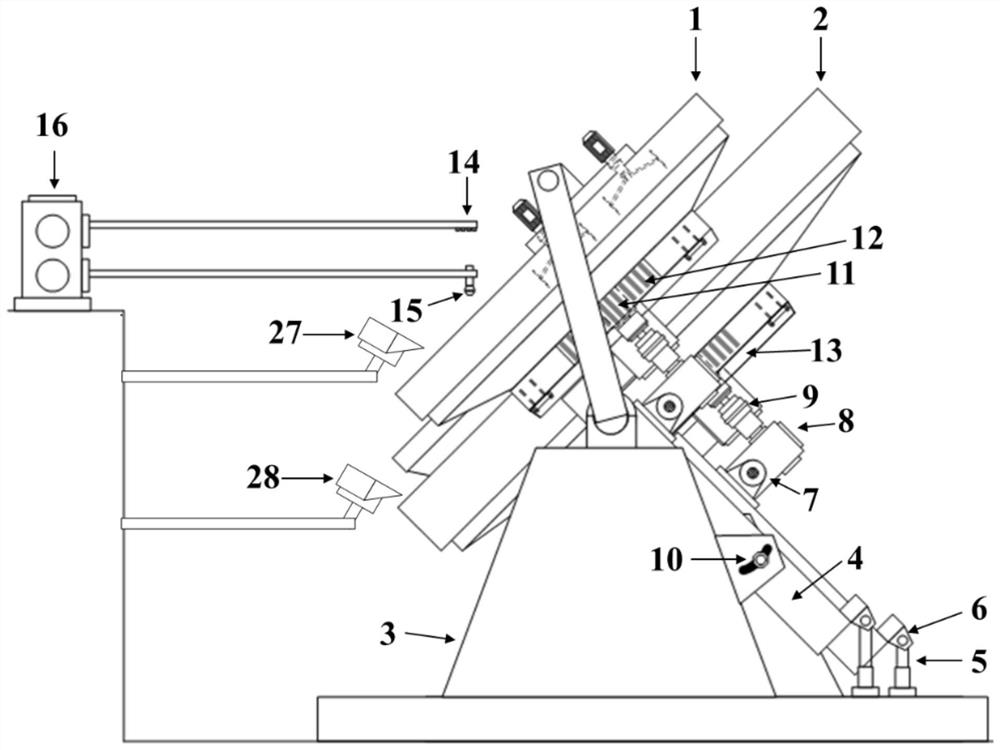

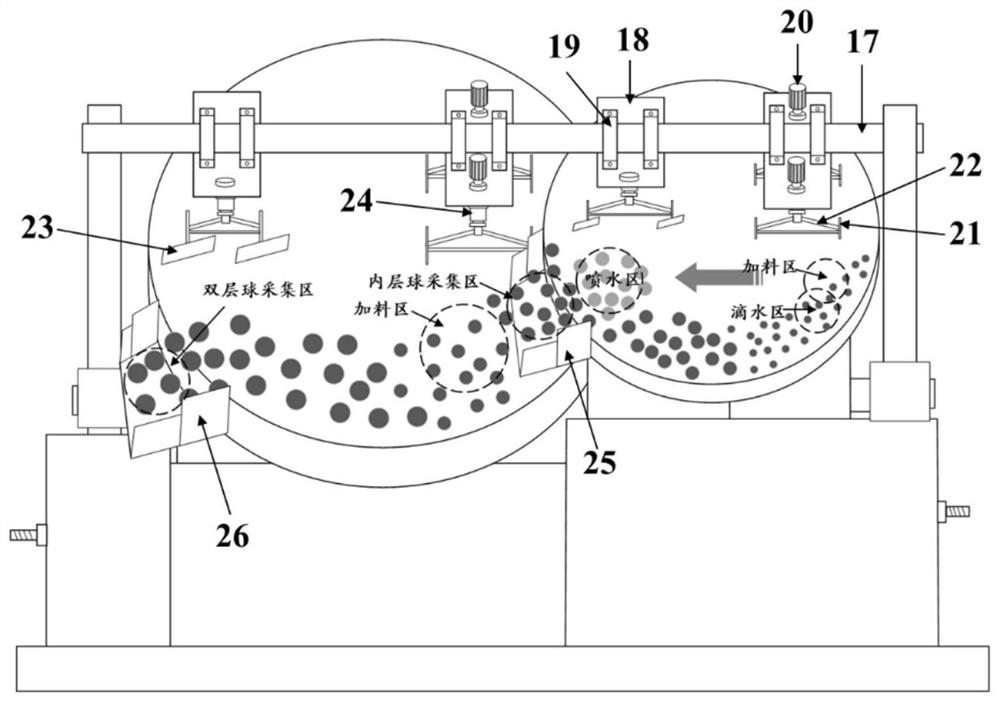

[0032] Such as figure 1 , figure 2 As shown, the double-disk pelletizer for manufacturing double-layer pellets disclosed in this embodiment has the following structural composition and working principle:

[0033] The main structure includes small-diameter disc 1, large-diameter disc 2, pelletizing machine base 3, two pelletizing machine support platforms 4, two sets of hydraulic lifting drive devices 5, two sets of rotating drive devices, and inner ball chute 25. Double-layer ball chute 26, dripper 14, mist water sprayer 15, four sets of scraper sets, and two sets of pellet particle size collection and analysis devices.

[0034] The pelletizing machine base 3 is fixed on the ground and is used to support the entire pelletizing equipment. The small diameter disk 1 makes the inner layer of the double-layer pellets, and the large diameter disk 2 makes the outer layer of the double-layer pellets.

[0035] The two pelletizing machine support platforms 4 are arranged left and ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com