Dry-type modified grinding method and system for hard and brittle materials

A dry modification technology for hard and brittle materials, applied in grinding/polishing equipment, grinding machines, stone processing equipment, etc., can solve the problems of difficulty in preparing special grinding wheels for ultra-fine abrasive wheels and difficult recovery of wet modification fluids, etc. Achieve the effect of low surface roughness and low grinding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

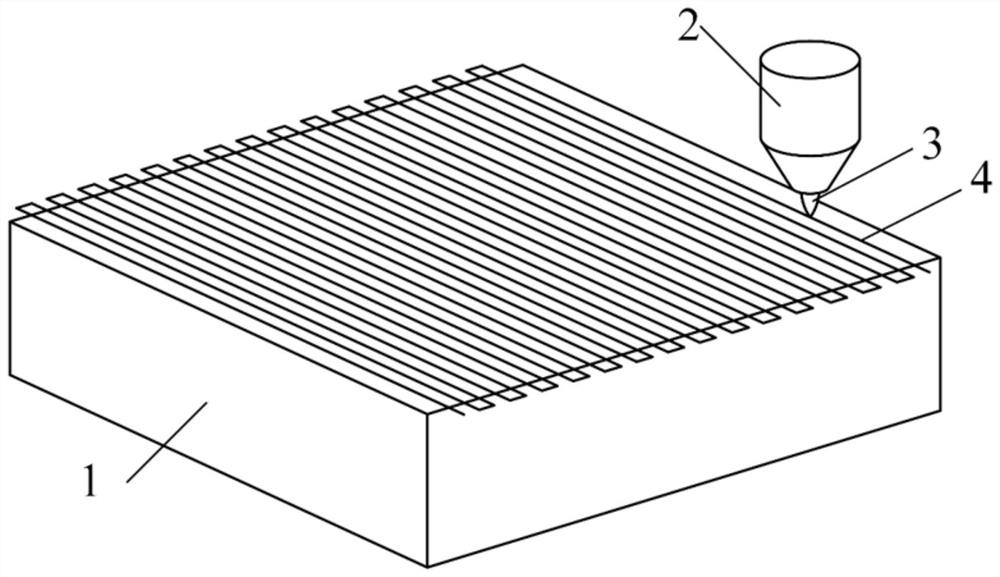

[0033] like figure 1 and figure 2 As shown, a dry modified grinding method for hard and brittle materials provided in this embodiment includes the following steps:

[0034] Step 1: Atmospheric plasma 3 is generated by the atmospheric plasma nozzle 2, and the atmospheric plasma nozzle 2 moves along the planned path 4 to process the hard and brittle material surface 6 of the hard and brittle material 1, and performs dry modification on the hard and brittle material surface 6; according to For the type of hard and brittle material 1, different mixed gases are selected to form atmospheric plasma 3, and the distance between the trajectory of atmospheric plasma nozzle 2 is adjusted according to the difference between the grinding surface and the microstructure; A hard and brittle material undergoing chemical action, the hard and brittle material 1 is one of quartz glass, sapphire, single crystal diamond or single crystal silicon carbide.

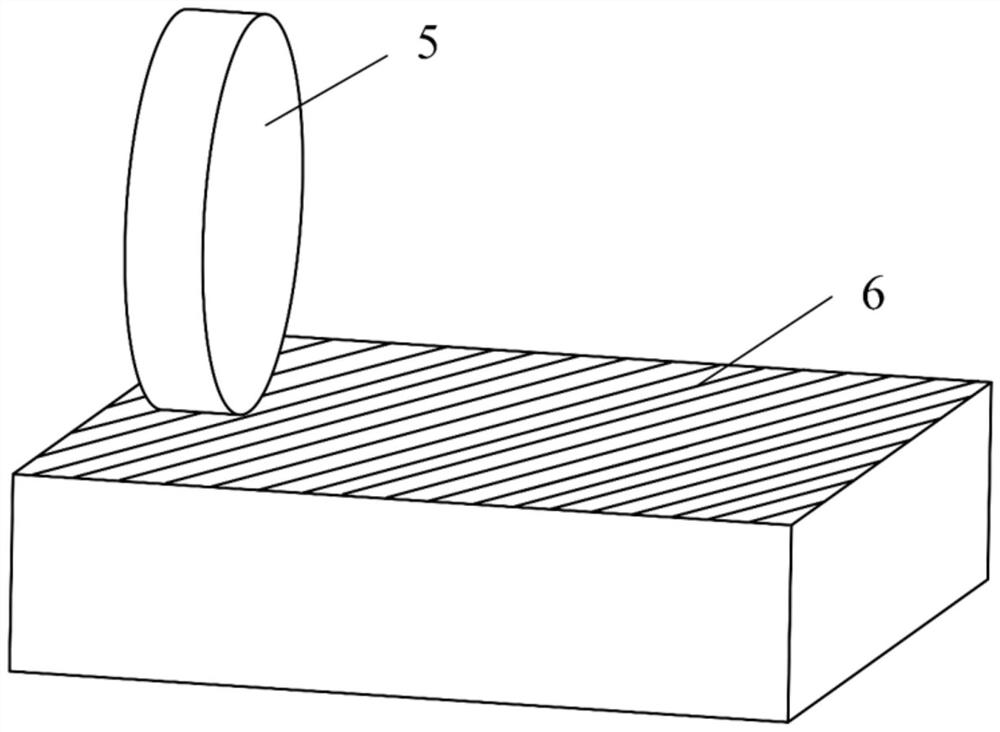

[0035] Step 2: Grinding the dry modified...

Embodiment 2

[0037] The present invention also provides a dry modified grinding system for hard and brittle materials, which includes the following modules:

[0038] Modification module: the atmospheric plasma 3 is generated by the atmospheric plasma nozzle 2, and the atmospheric plasma nozzle 2 moves along the planned path 4 to process the hard and brittle material surface 6 of the hard and brittle material 1, and performs dry modification on the hard and brittle material surface 6;

[0039] Processing module: the grinding tool 5 is controlled by a numerical control grinding machine to perform grinding processing on the surface 6 of the dry modified hard and brittle material.

Embodiment 3

[0041] Those skilled in the art can understand this embodiment as a more specific description of Embodiment 1 and Embodiment 2.

[0042] A dry modified grinding method for hard and brittle materials provided in this embodiment includes: Atmospheric plasma selection step for hard and brittle materials: For the type of hard and brittle materials, select the atmospheric plasma that can chemically react with the material to generate a mixed gas ; Atmospheric plasma dry modification step: Use atmospheric plasma nozzle to modify the surface of hard and brittle materials along the moving track; Processing control step: Control grinding wheel feeding and grinding to process hard and brittle materials by CNC machine tools to efficiently obtain low surface roughness Grinding the workpiece.

[0043] Specifically, a diamond grinding wheel is used to grind the surface of the workpiece dry modified by atmospheric plasma through a numerically controlled grinding machine with a minimum resolu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap