Construction method for rapidly mounting ALC plate

A construction method and fast technology, applied in the direction of hoisting device, transportation and packaging, construction material processing, etc., can solve the problems of low installation efficiency, inconvenient use, large floor space, etc., to achieve strong adaptability and reduce missed mistakes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

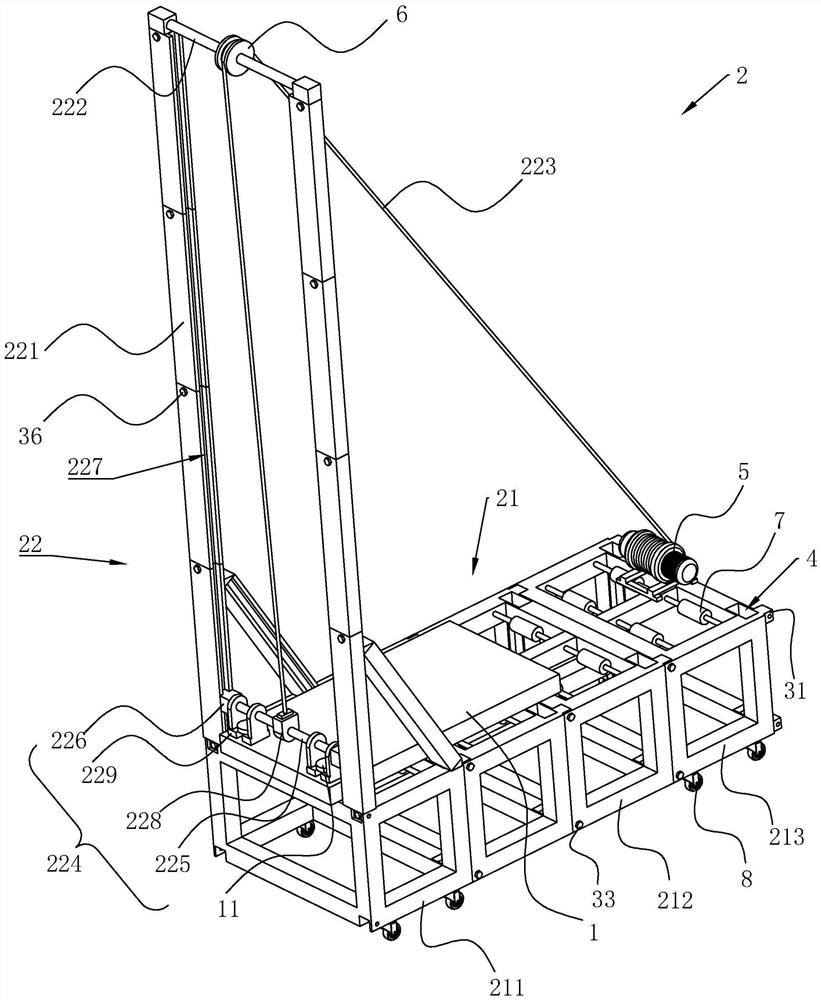

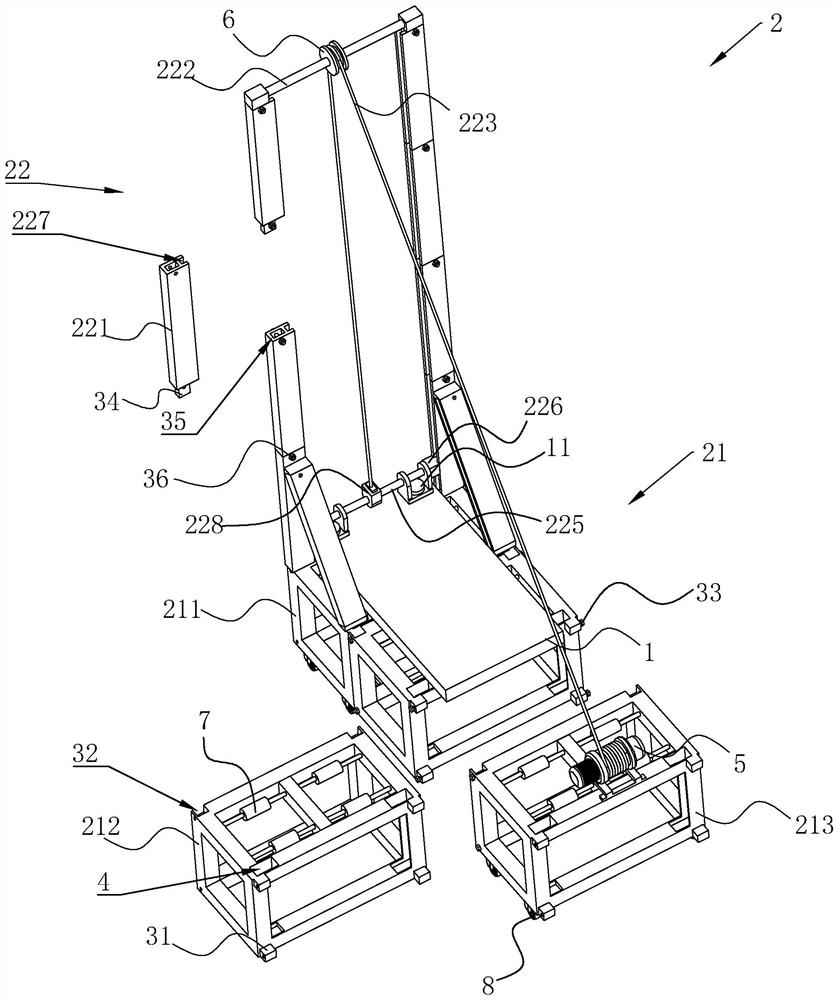

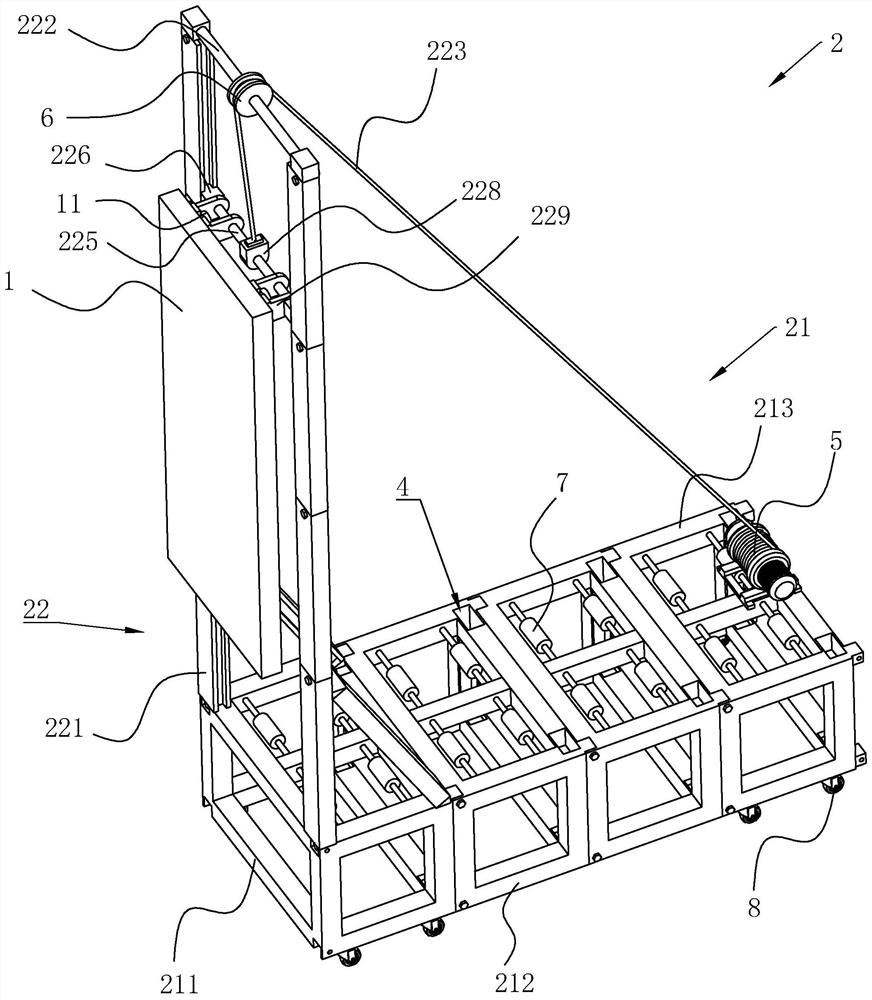

[0041] The following is attached Figure 1-3 The application is described in further detail.

[0042] The embodiment of the present application discloses a construction method for quickly installing ALC panels, such as figure 1 shown, including the following steps:

[0043] Step 1: Perform pretreatment on the ALC board 1, install the wall fittings on the side of the ALC board 1 and install the hoisting piece 11 on the front; The head is drilled into the front of the ALC board 1 near the end, and the wall connecting piece can adopt a conventional ALC board 1 tube clip.

[0044] Step 2: By manual or trolley handling, place the ALC board 1 horizontally on the loading area of the installation machine 2, and translate the ALC board 1 until the lifting piece 11 is located under the lifting frame 224 of the installation machine 2, and connect the lifting frame 224 and the lifting piece 11 connections;

[0045] Step 3: Adjust the attitude of the ALC board 1, control the ALC inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com