A composite pipe with a quick-connect pipe head

A composite pipe and joint head technology, applied in the field of composite pipes, can solve the problems that the raw tape is easily corroded by underground substances, increase the labor intensity of pipeline construction, and reduce the protection effect of optical fiber and cable, so as to improve the utilization rate of glue and realize self-protection. The effect of positioning guidance and improving integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

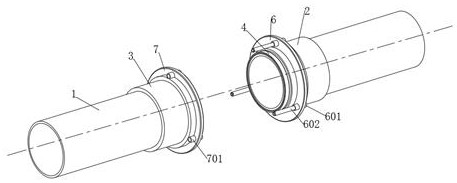

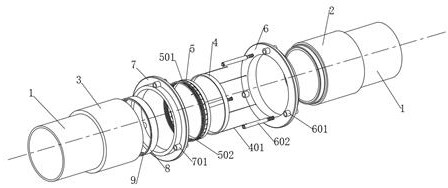

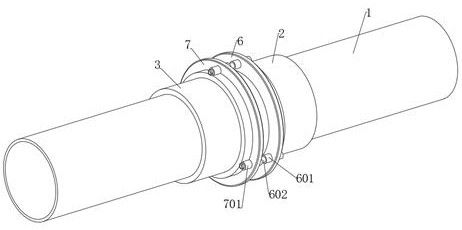

[0044] see Figure 1-11 , a composite pipe with a quick-connect pipe head, including two composite pipe bodies 1, the left end of the composite pipe body 1 on the right side is fixedly connected with a quick-connect female guide sleeve 2, and the left end of the quick-connect female guide sleeve 2 is fixedly connected with a dislocation insert 201, the left end of the composite pipe body 1 on the right side is aligned with the left end of the dislocation inserting plate 201, the outer end of the dislocation inserting plate 201 is slidably connected with an annular magnetic push plate 4, and the right end of the composite pipe body 1 on the left side is fixedly connected with a quick-connect male guide sleeve 3 , the right end of the composite pipe body 1 on the left side is aligned with the right end of the quick-connect male guide sleeve 3, the right end of the misplaced spacer ring 301 extends to the outside of the composite pipe body 1, and the right end of the quick-connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com