New energy motor power system practical training platform

A power system and training platform technology, applied in the direction of motor generator testing, measuring electricity, measuring electrical variables, etc., can solve problems affecting normal driving, etc., and achieve obvious beneficial effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

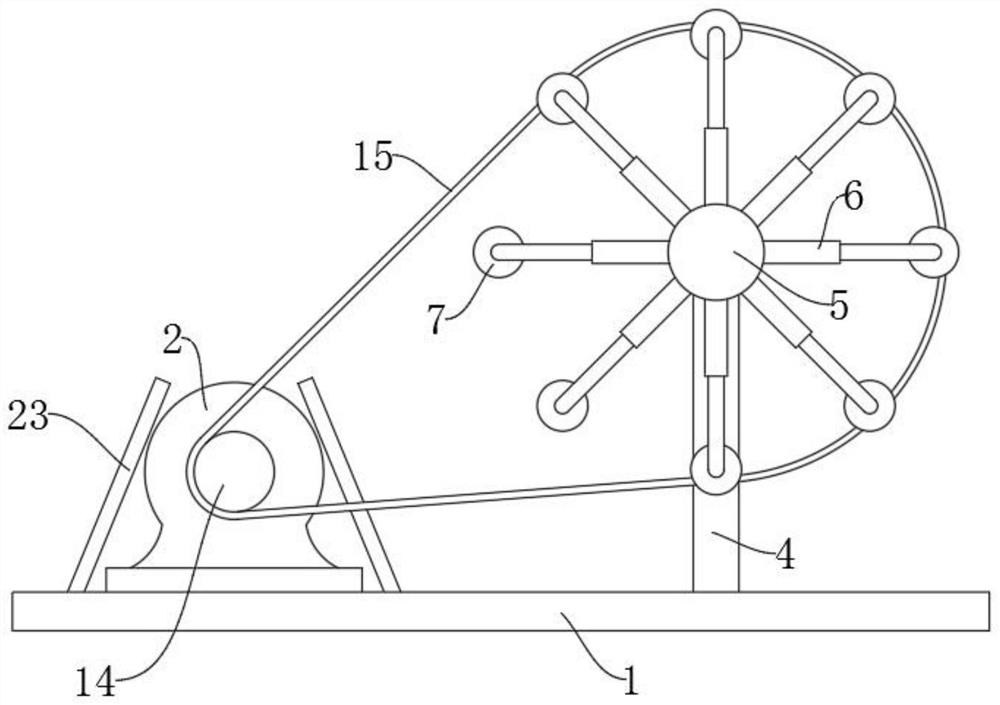

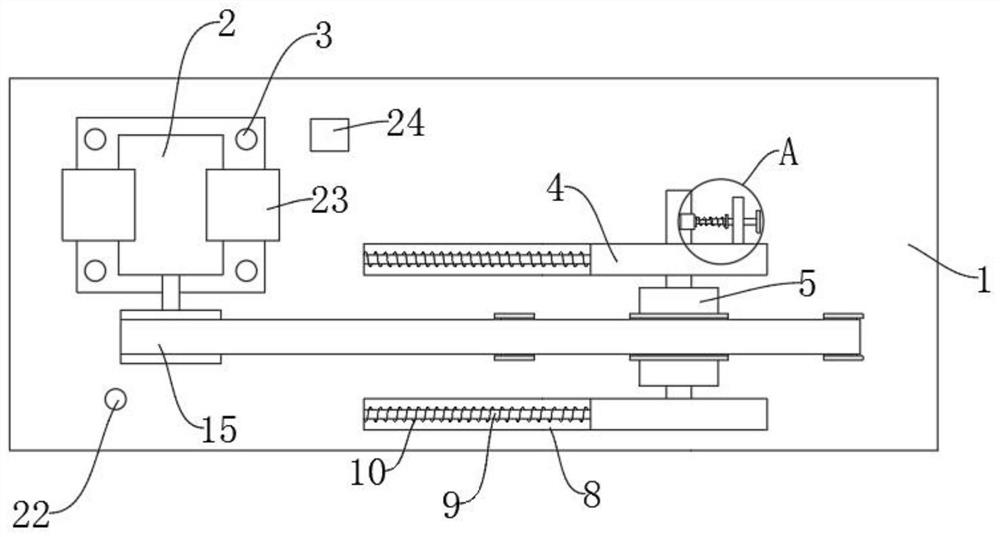

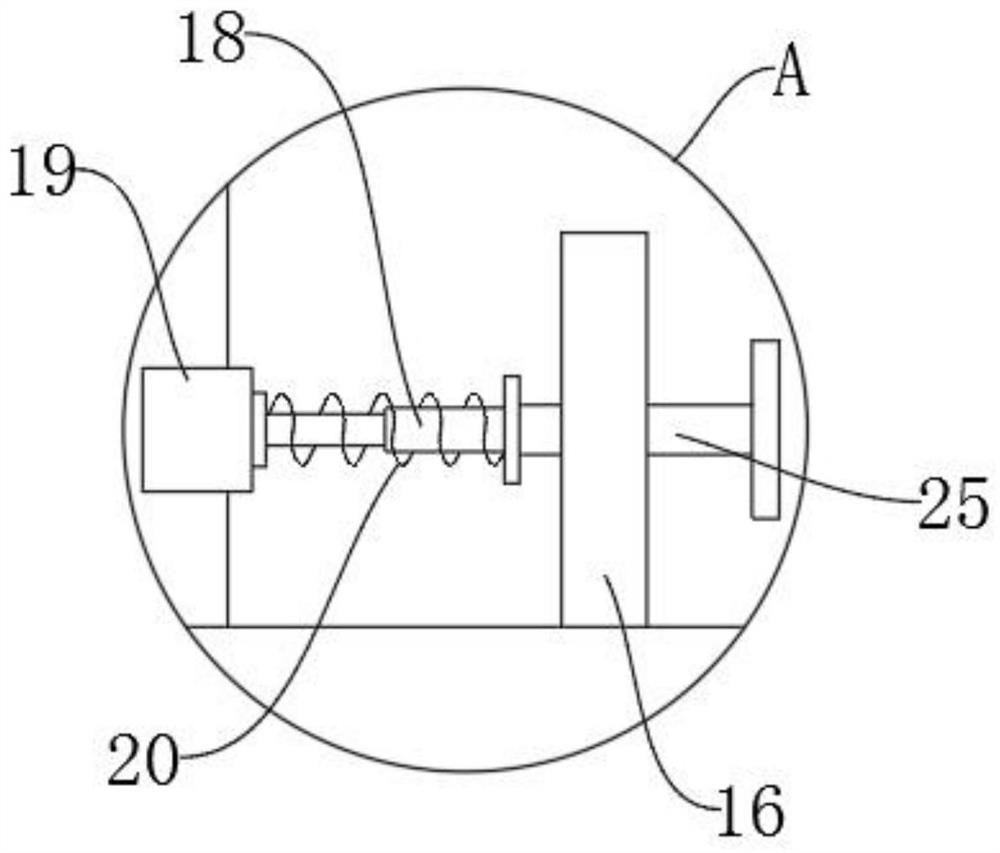

[0020] refer to Figure 1-4 , a new energy motor power system training platform, including a base 1 and a motor 2 installed on the base 1, the four corners of the motor 2 are provided with fixing holes 3, and the fixing holes 3 are matched with threaded connections on the base 1, the base 1 is provided with a driving force detection mechanism, the base 1 is fixedly connected with a swash plate 23, the shell of the motor 2 is matched with the inner side wall of the swash plate 23, and the inner side wall of the swash plate 23 is fixedly provided with A thin-film pressure sensor, a horn 24 is fixedly installed on the base 1, and a speed sensor 22 is fixedly installed on the base 1 close to the output end of the motor 2, which can be used to measure the rotation speed of the motor 2, by setting a swash plate 23 near the motor 2 , the inner wall of the swash plate 23 is fit with the gap between the motor 2 shell, and the inner wall of the swash plate 23 is fixedly provided with a ...

Embodiment 2

[0022] refer to Figure 1-4 , as another preferred embodiment of the present invention, the difference from Embodiment 1 is that the driving force detection mechanism includes a bracket 4, a rotating shaft 5, an electric telescopic rod 6 and a transmission wheel 7, the bracket 4 is slidably arranged on the base 1 and the bracket 4 There is a passive drive mechanism between the base 1, the rotating shaft 5 is set on the top of the bracket 4, the number of electric telescopic rods 6 is fixed on the outer wall of the rotating shaft 5 at an equal angle, and the transmission wheel 7 is fixedly connected to the electric telescopic rod 6 One end away from the rotating shaft 5, the output end of the motor 2 is fixedly connected with a synchronous pulley 14, and a belt 15 is sleeved between the transmission wheel 7 and the synchronous pulley 14. Under the action of the electric telescopic rod 6, the transmission wheel 7 and the rotating shaft 5 The distance between them is adjustable, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com