Supplier default risk prediction method

A risk prediction and supplier technology, applied in the field of supplier default risk prediction, can solve problems such as lack of research and single data dimension, and achieve the effect of ensuring safe operation and reducing business risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

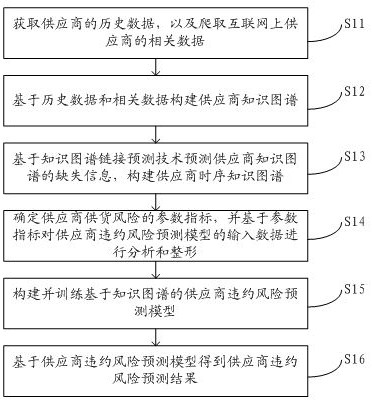

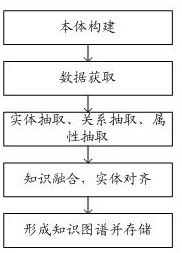

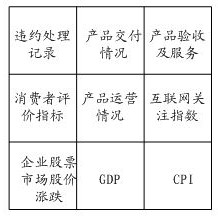

[0021] The present invention aims to propose a supplier default risk prediction method, based on the five principles of the risk index system, combined with the characteristics of the manufacturing industry, to systematically analyze the factors that affect the supplier default risk of manufacturing enterprises, and use related indicators to Quantification of influencing factors. Aiming at problems such as supplier default in manufacturing enterprises, the RLSTM neural network structure is used to predict the risk of supplier default, and the supplier information is integrated into the supplier knowledge map, and the knowledge map link prediction technology is used to predict the supplier knowledge map. Completion, the information of related suppliers of adjacent parts is input into the RLSTM model through shaping, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com