Method, device and system for correcting LED display device

A technology of a display device and a correction method, which is applied to static indicators, instruments, etc., can solve problems such as increased difficulty in point positioning, inaccurate point positioning, and affecting color correction efficiency, achieving accurate point positioning results and improving correction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

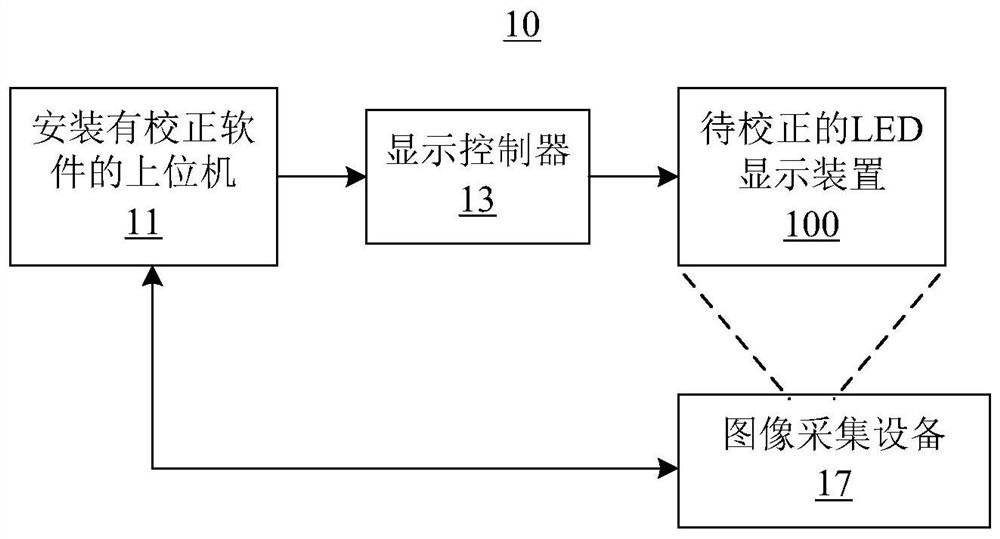

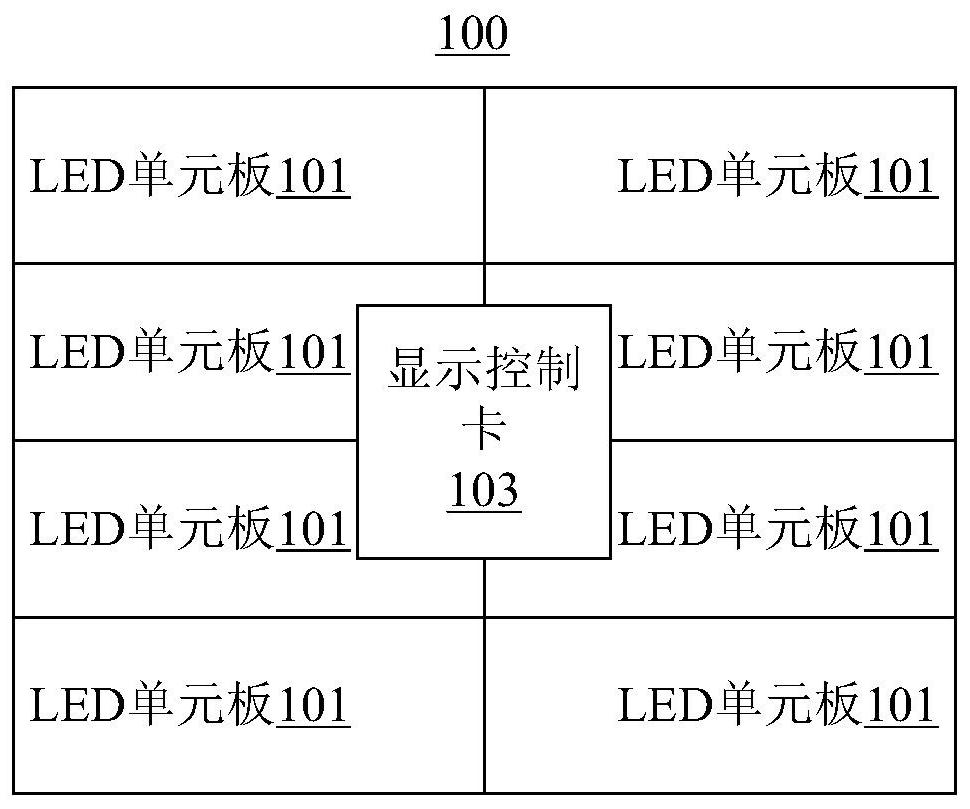

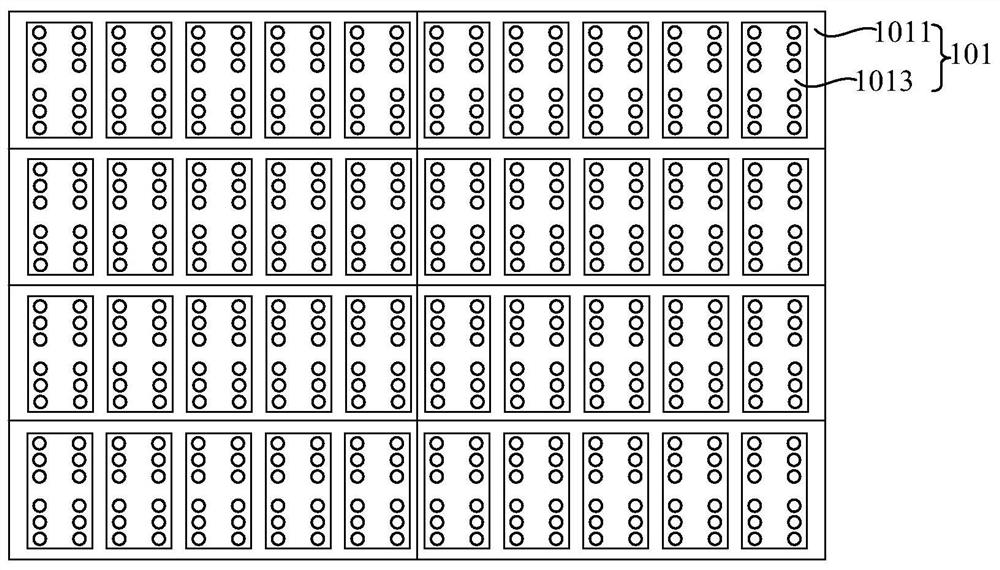

[0032] A calibration method for an LED display device provided by the first embodiment of the present invention, for example, is suitable for using figure 1 A calibration system 10 for an LED display device is shown. Such as figure 1 As shown, the calibration system 10 includes: a host computer 11 installed with calibration software, a display controller 13 and an image acquisition device 17, which can be used to perform color calibration such as brightness calibration or brightness chromaticity calibration on the LED display device 100 to be calibrated. Furthermore, if Figure 2A As shown, the LED display device 100 is an LED display box, which includes a plurality of LED unit boards 101 spliced together and a display control card 103 electrically connected to the plurality of LED unit boards 101; but the implementation of the present invention The example is not limited to this, and the LED display device 100 can also be composed of multiple Figure 2A The shown LED dis...

no. 2 example

[0052] see Figure 8 An embodiment of the present invention provides a calibration device 80 for an LED display device. The LED display device includes a plurality of LED unit boards spliced together and a display control card electrically connected to the plurality of LED unit boards (such as Figure 2A and Figure 2B shown), each of the LED unit boards includes a circuit board and a plurality of COB-type LED modules arranged on the circuit board so that the plurality of COB-type LED modules of the plurality of LED unit boards together form a COB type LED module array, each of the COB type LED modules includes a plurality of LED pixels that are independently controlled, and each of the LED pixels includes a plurality of different color LEDs; the calibration device 80 includes: including: a display control module 81 , an acquisition control module 83 and a coefficient generation module 85 .

[0053] Wherein, the display control module 81 is, for example, used to send an im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com