Copper bar protection structure, battery pack and electric vehicle

A technology for protecting structures and copper bars, applied in the automotive field, can solve the problems of PI film wear and tear on the outer surface of copper bars, leakage and other problems, and achieve the effects of avoiding the risk of copper bar leakage, enhancing safety performance, and improving installation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present application will be clearly described below in conjunction with the accompanying drawings.

[0022] The copper bar protection structure in the embodiment of the present application can be used in a battery pack of an electric vehicle, and its function is to connect different battery cell modules in the battery pack to realize the electrical connection between the battery modules.

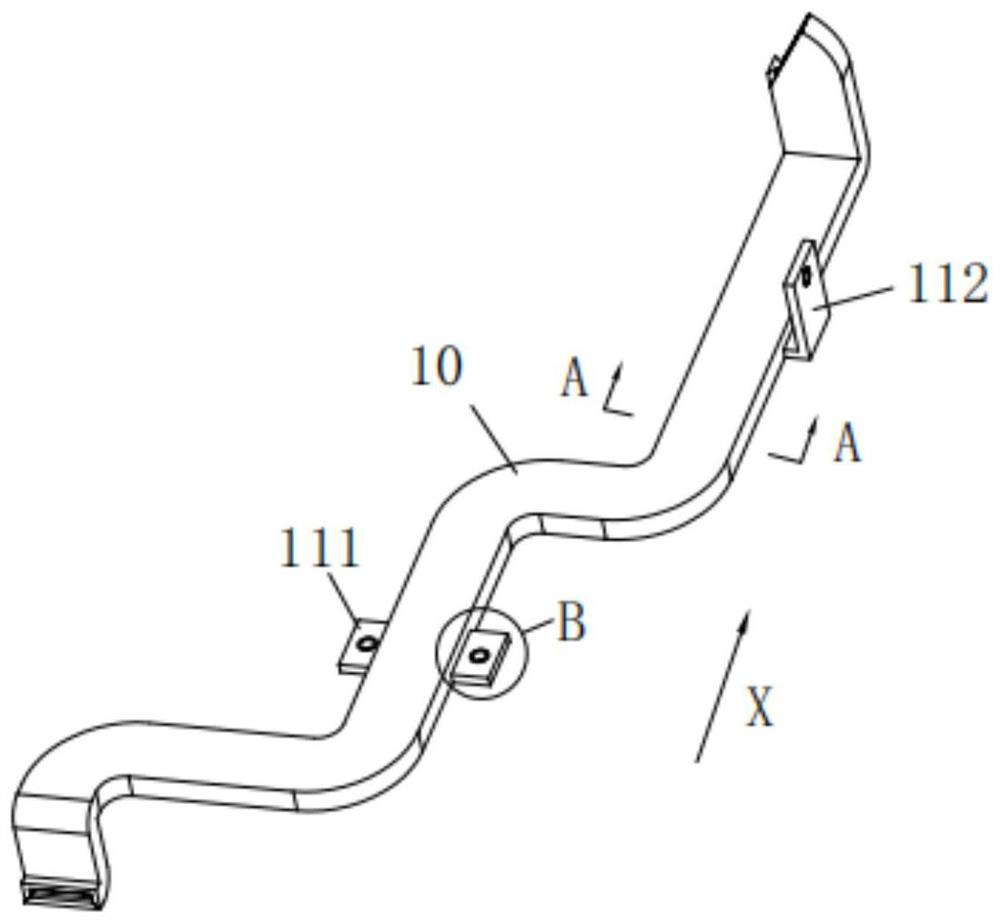

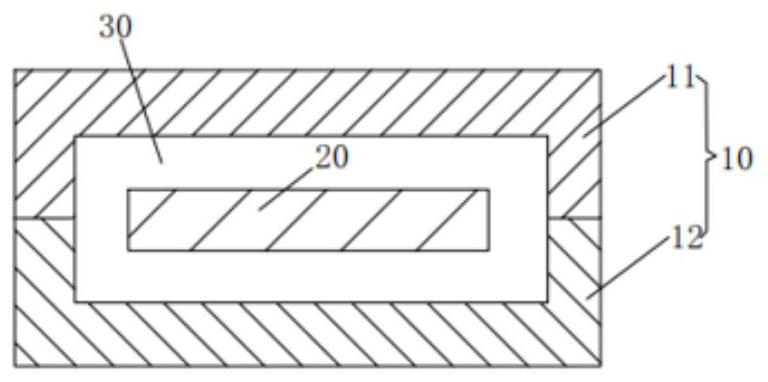

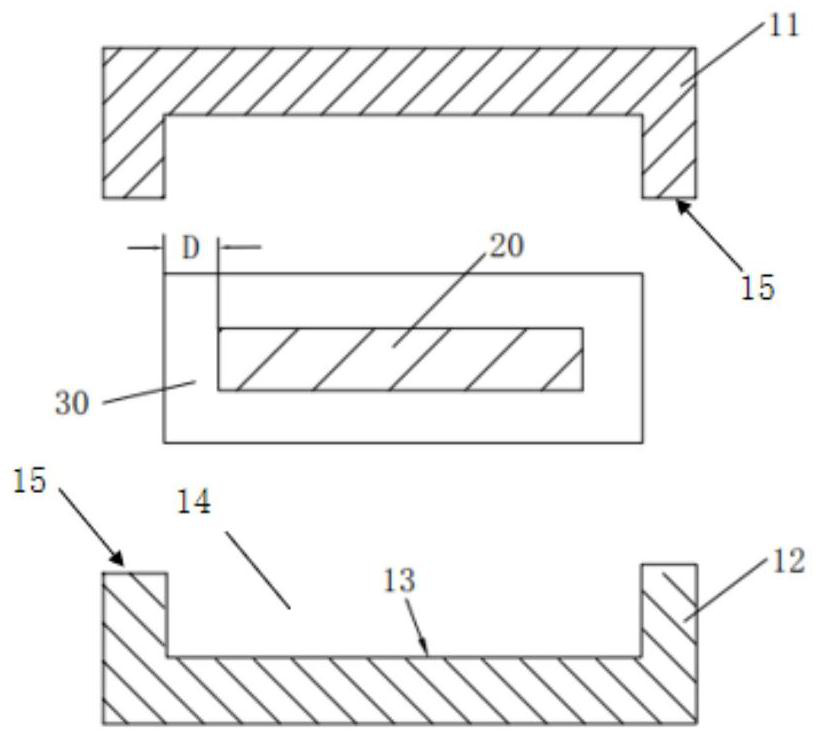

[0023] Please also refer to Figure 1 to Figure 4 , figure 1 It is a structural schematic diagram of the copper bar protection structure of the embodiment of the present application, figure 2 is a cross-sectional view of the copper row protection structure along the A-A cutting line, image 3 is in figure 2 An exploded view in the case of a cutaway view, Figure 4 It is an exploded view of the protective structure of copper bars.

[0024] The copper bar protection structure 10 in the embodiment includes an upper shell 11 and a lower sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com