Automatic nuclear track membrane cleaning device and nuclear track membrane sewage treatment system

A technology of automatic cleaning and nuclear pore membrane, which is applied in water/sewage treatment, water/sludge/sewage treatment, permeation/dialysis water/sewage treatment, etc. It can solve the problems of membrane pore clogging, dirt adsorption, and affecting the filtration effect, etc. , to achieve the effect of improving cleaning efficiency, meeting normal operation requirements, and ensuring timeliness and effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

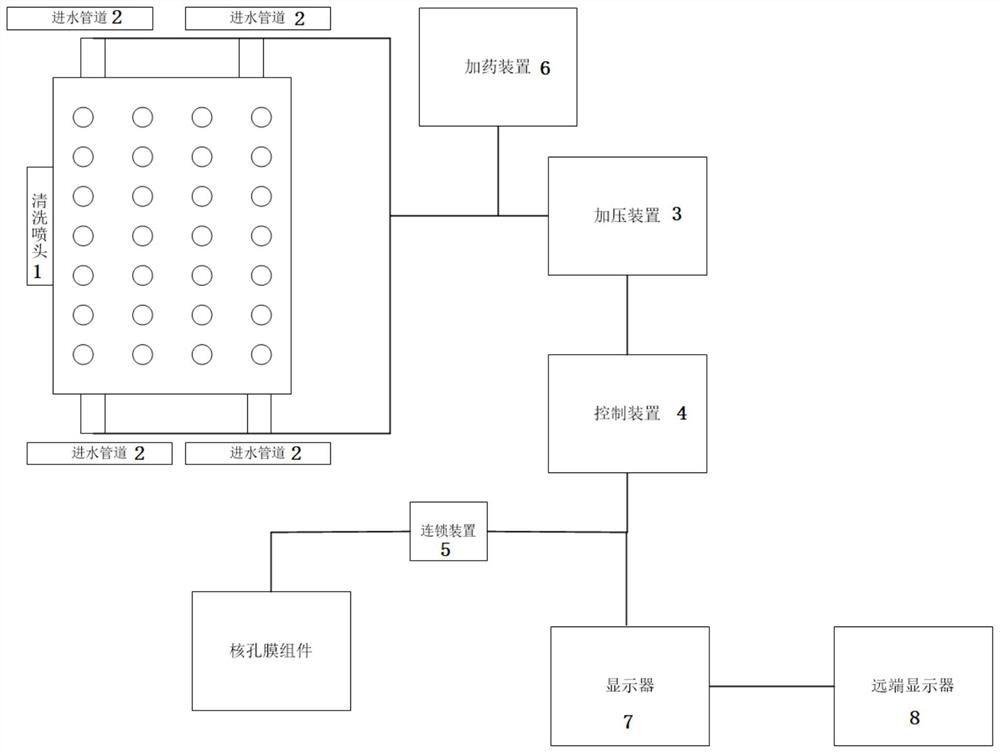

[0041] Such as figure 1 , figure 2 As shown, the nuclear pore membrane automatic cleaning device provided in this embodiment includes a cleaning nozzle 1 , a water inlet pipe 2 , a pressurizing device 3 , a control device 4 and an interlocking device 5 .

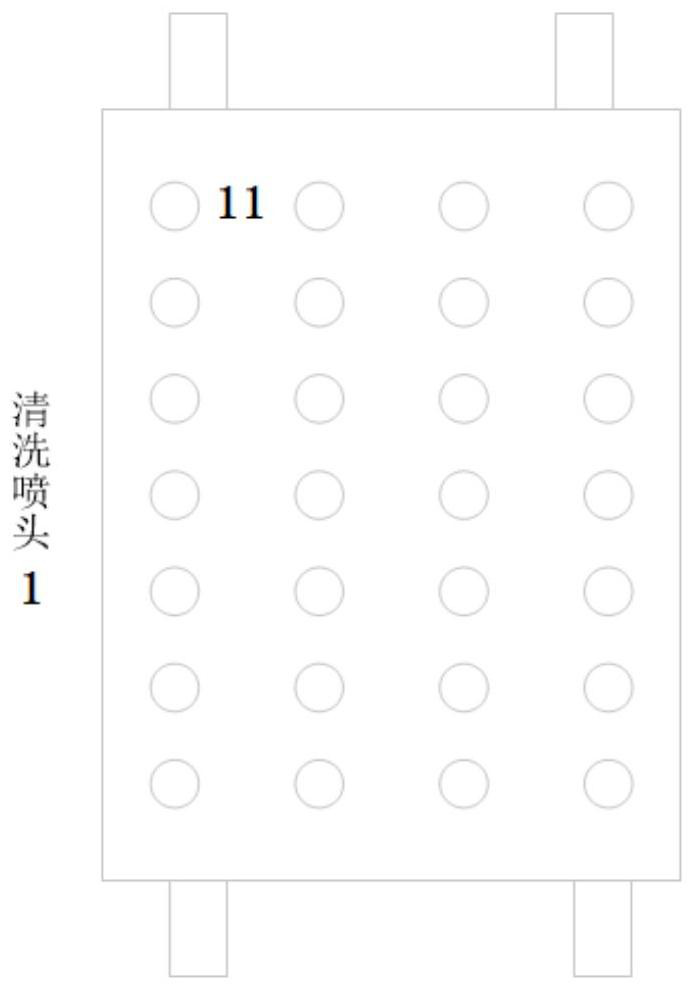

[0042] The number of cleaning nozzles 1 is set to several. In order to fully clean the nuclear pore membrane module, the cleaning nozzle 1 matches the size of the nuclear pore membrane module to be cleaned. When in use, the cleaning nozzle 1 and the nuclear pore membrane assembly can be fixed.

[0043] Specifically, each cleaning spray head 1 includes a sealed casing, and a plurality of nozzles 11 are arranged in an array on the sealed casing. Preferably, the nozzles 11 may be rectangular or circular, etc., which are not limited herein. The distribution density of the nozzles 11 is subject to completely covering the nuclear pore membrane module to be cleaned, that is, the density and number of the nozzles 11 can be arrang...

Embodiment 2

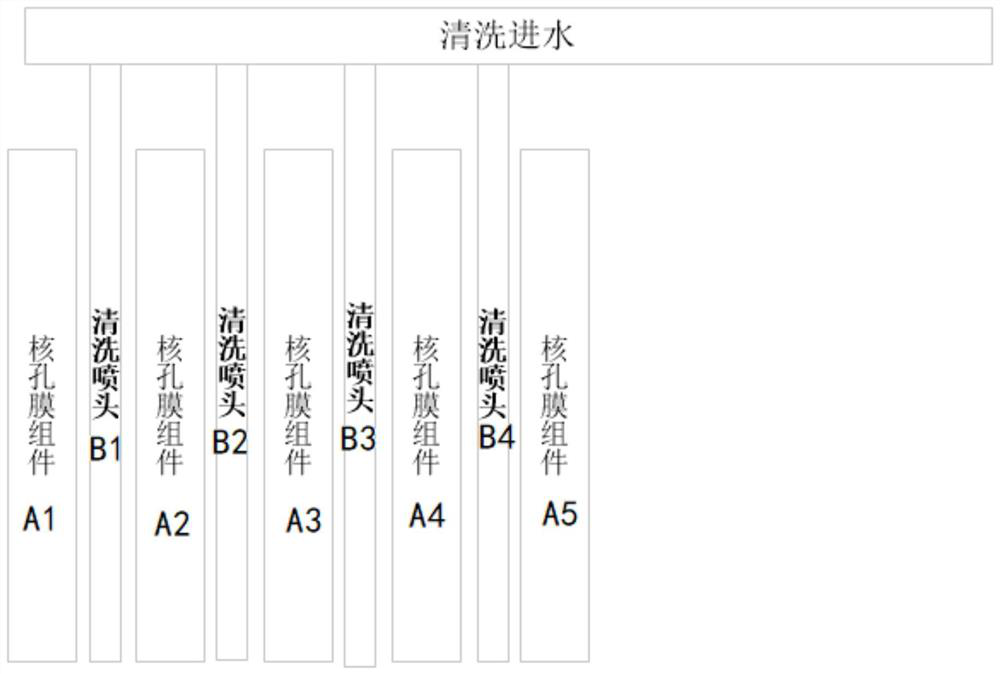

[0062] Such as Figure 5 As shown, the nuclear pore membrane sewage treatment system provided in this embodiment includes a sewage water inlet main pipe 7, a sewage water inlet pipe 8, a sewage treatment unit 9, a clear water outlet pipe 10, a clear water outlet main pipe 11, and the nuclear pore membrane of Example 1 Automatic cleaning device;

[0063] The sewage enters the sewage treatment unit 9 through the sewage water inlet main pipe 7 and enters the sewage treatment unit 9 through the sewage water inlet pipe 8, and is filtered through the nuclear pore membrane modules set in the sewage treatment unit 9, and the filtered clean water passes through the water purification pipes 10 Discharge the filtered clean water through the clear water outlet main pipe 11 to complete the nuclear pore membrane sewage treatment process. If there is dirt on the surface of the nuclear pore membrane module, start the nuclear pore membrane automatic cleaning device to fully clean the dirt on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com