Method for machining yawing gear ring

A processing method and technology for a ring gear, applied in the processing field of the ring gear, can solve the problems of the reliability and poor stability of the yaw ring gear, the unsatisfactory braking effect of the yaw ring gear, and the inability to meet the needs of the normal operation of the wind turbine. , to achieve the effect of good process performance and ideal braking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

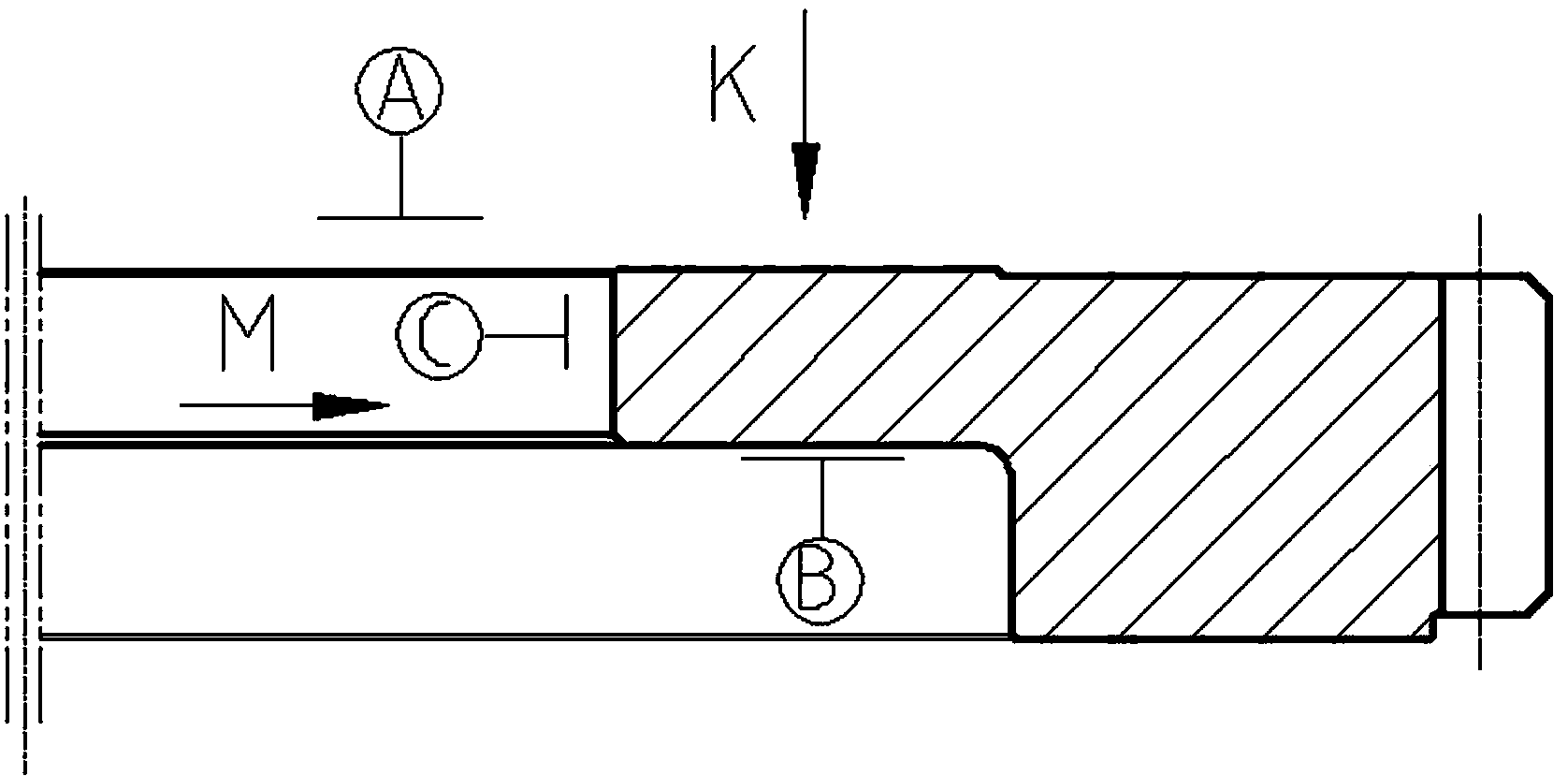

[0021] A method for processing a yaw ring gear, comprising the following process steps:

[0022] 1. Fix the yaw ring gear blank on the workbench of the CNC vertical lathe, position and clamp it with a jig, then start the CNC vertical lathe, and carry out rough machining according to the set size. Make sure to leave two braking surfaces and inner holes machining allowance;

[0023] 2. Quenching and tempering the rough-machined yaw ring gear in step 1 after normalizing, and finish turning after passing the inspection by the managerial test center;

[0024] 3. Remove the turning stress, and perform high temperature tempering after turning, the tempering temperature is 450-540°C;

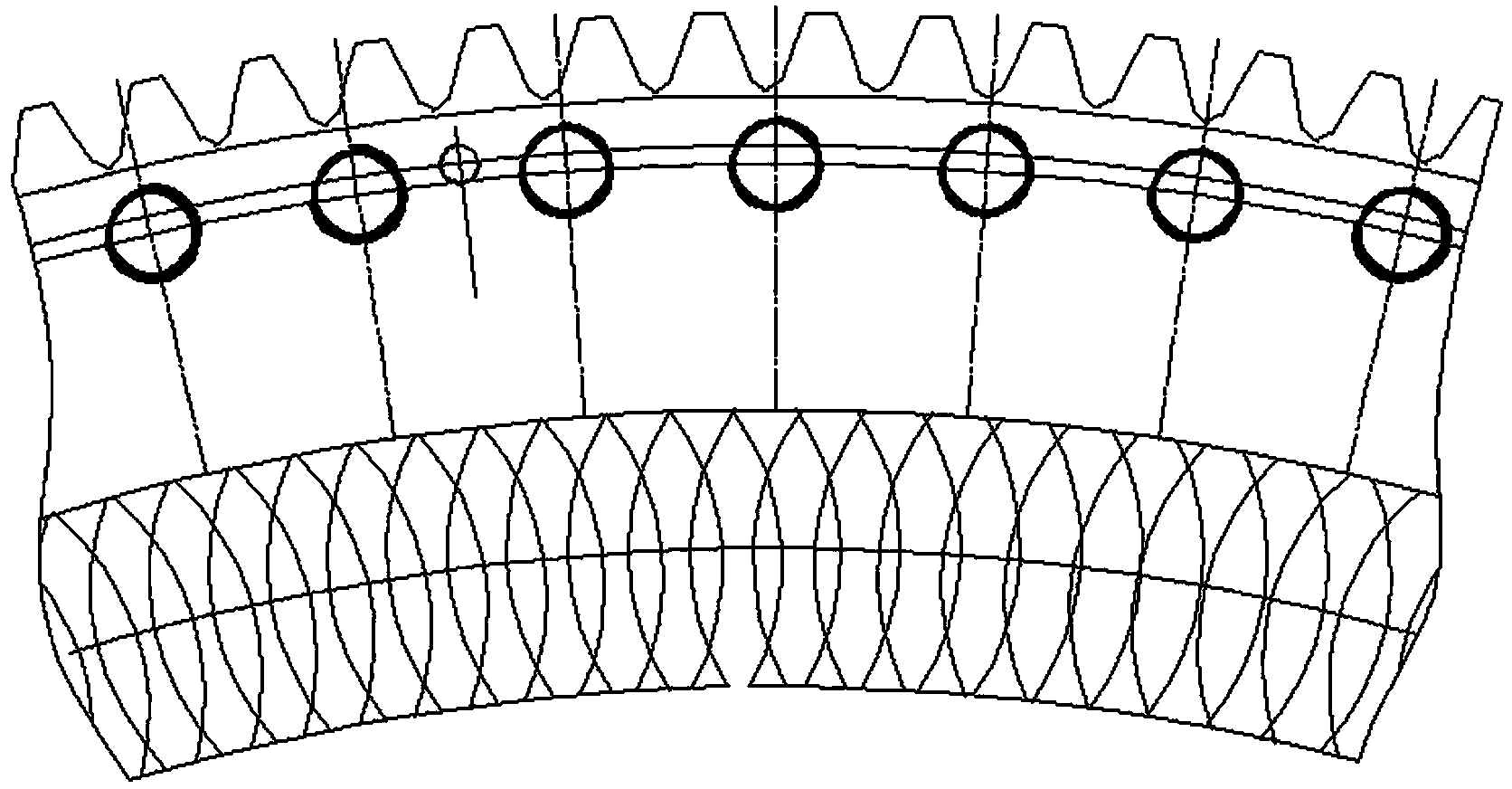

[0025] 4. Refine the size of each part of the above-mentioned yaw ring gear after high-temperature tempering, and leave 2.0mm nitriding allowance for the outer tooth surface;

[0026] 5. Drilling and milling center drilling and tapping;

[0027] 6. A bowl-shaped white corundum grinding wheel with a p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface smoothness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com