Casting mold

A mold and outer cylinder technology, applied in the direction of casting mold, equipment for feeding molten metal into the casting mold, casting mold composition, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

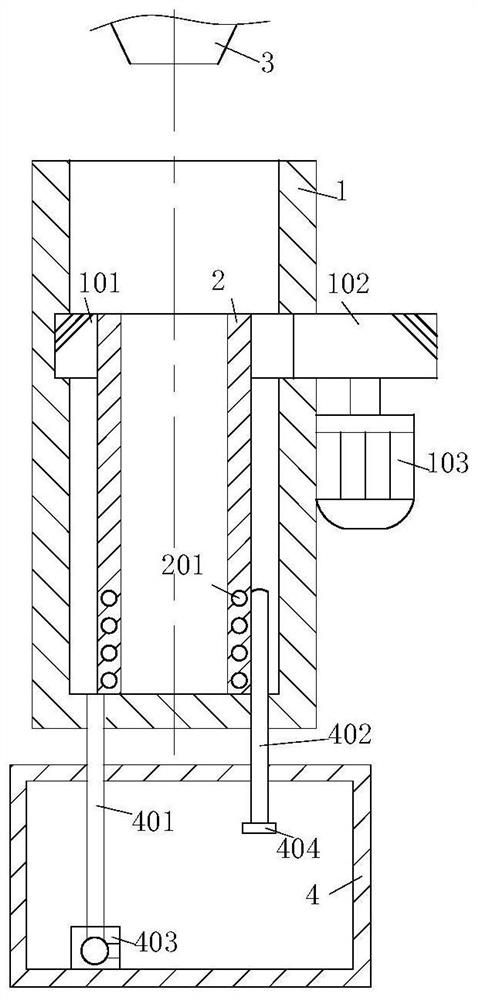

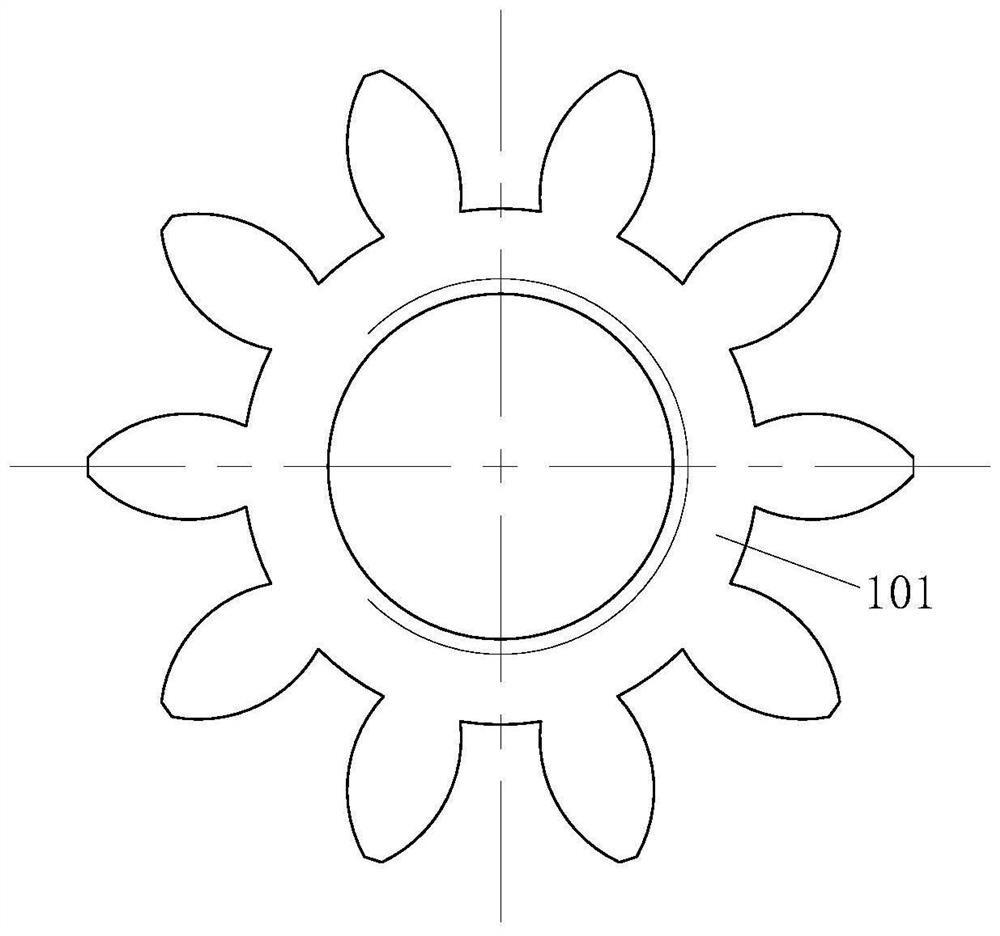

[0022] As a specific embodiment of the present invention, a through hole is provided in the middle of the No. 1 gear 101 , and the casting pipe 2 is connected to the through hole with internal threads.

[0023] The No. 2 gear 102 on the motor 103 of the present invention drives the No. 1 gear 101 to rotate, and then the melting and casting pipe 2 uses threads to move up and down while rotating in the outer cylinder 1, thereby realizing the length change of the melting and casting pipe 2, and then for processing bars of different lengths Provide the basis.

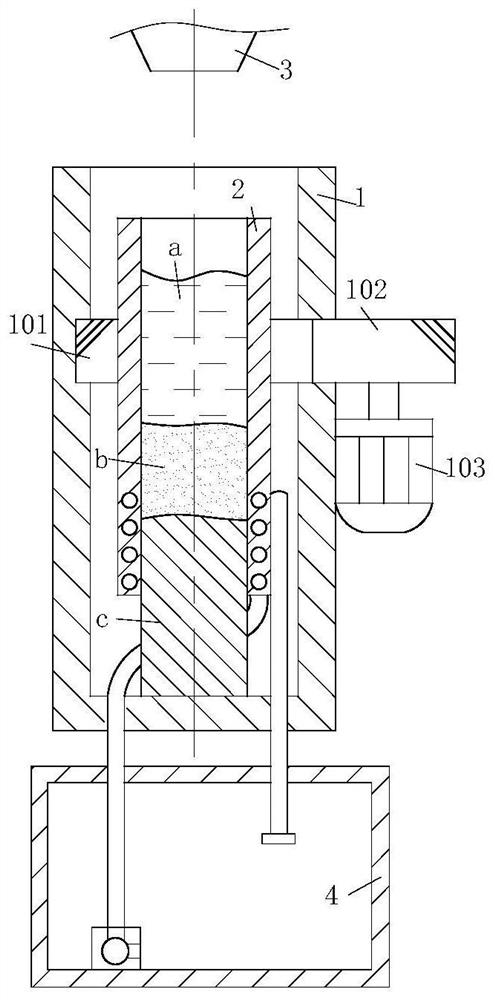

[0024] As a specific embodiment of the present invention, a water tank 201 is provided near the bottom of the casting pipe 2. On the one hand, the cold water circulates in the water tank 201 to quickly cool the molten metal into a rod; The molten metal in the casting pipe 2 is divided into three states, the first state a is a liquid state, the second state b is a solid-liquid coexistence state, and the third state c is a so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com