Automatic jacking and breaking mechanism for casting part

A casting and jacking technology, which is applied in the configuration of casting equipment, manufacturing tools, indicating equipment/measuring equipment, etc., can solve the problems of manpower consumption, inconvenient handling, heavy weight, etc., to prevent invalid continuous pushing and solve the problem of manpower Harsh environment, the effect of realizing safe automatic jacking off work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

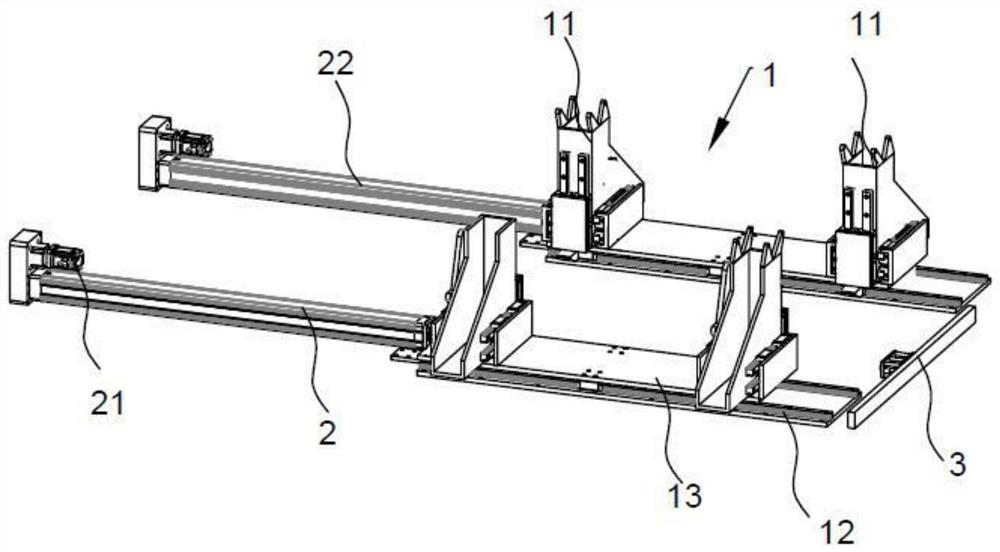

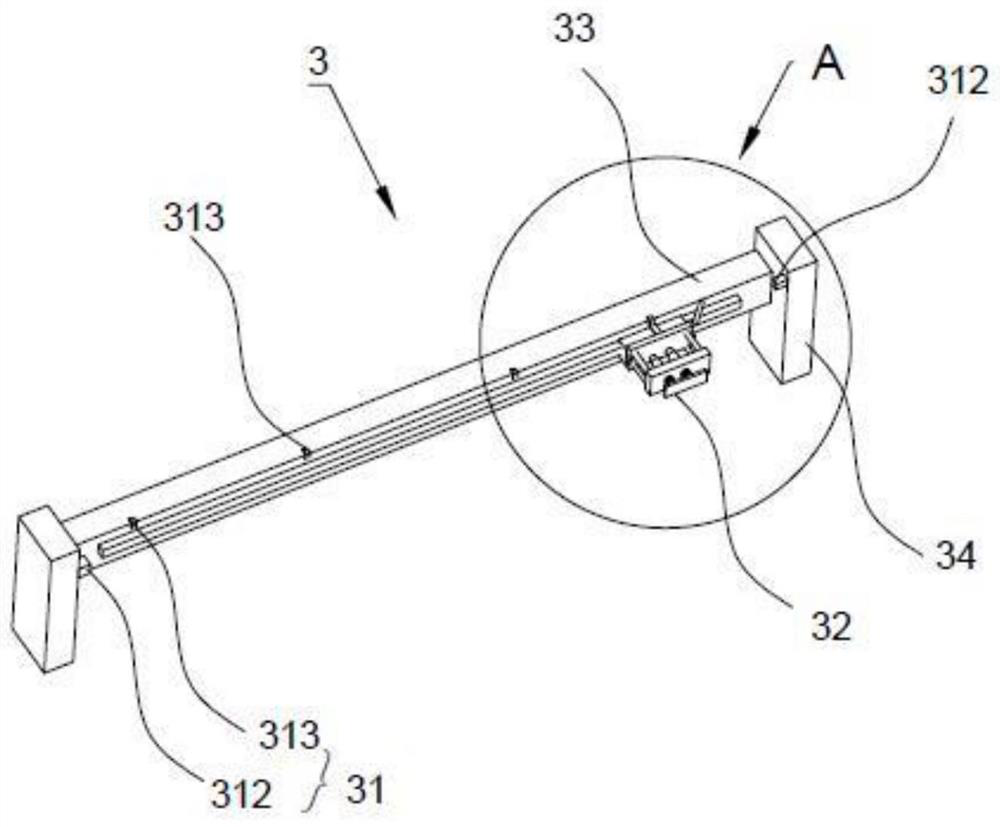

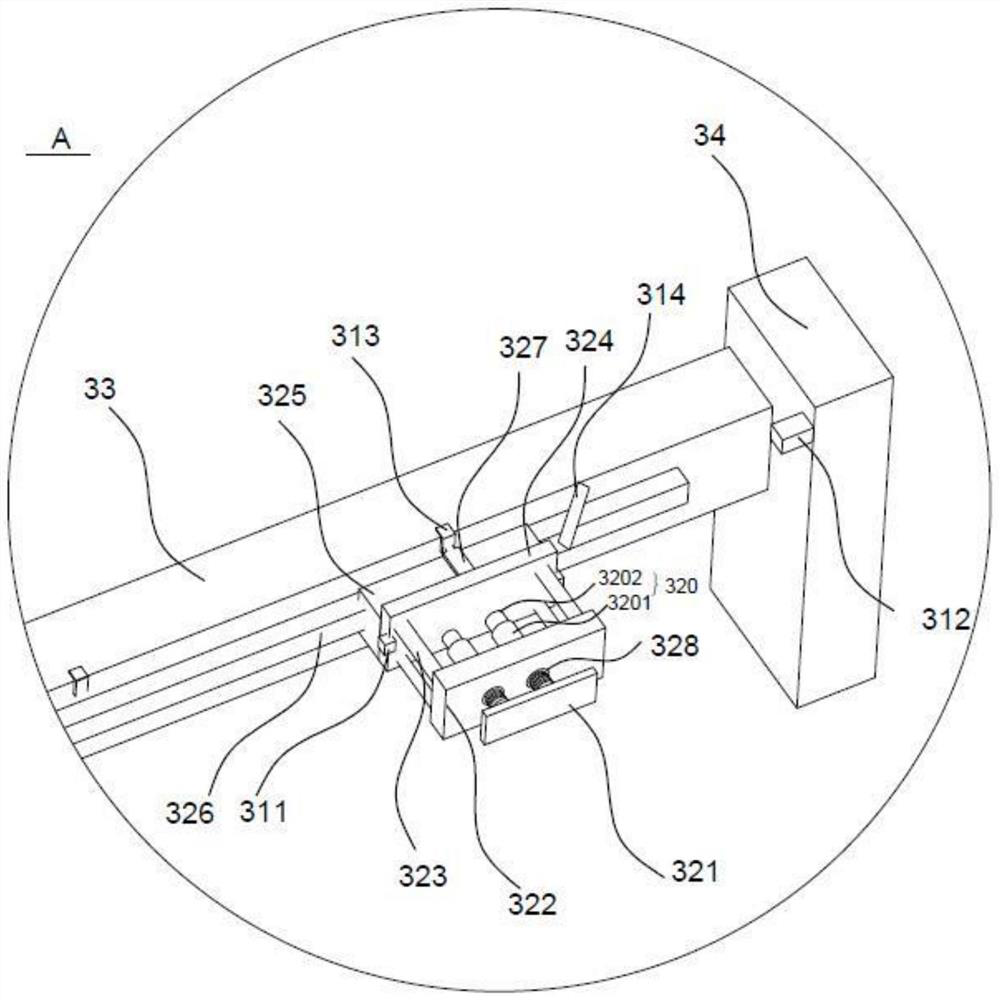

[0044] An automatic lifting mechanism for castings, including a loading structure 1, which is located on the first track 12 below the feeding track, and is used to place and fix casting racks conveyed from the feeding track; a lifting power structure 2 , the structure is located behind the loading structure, connected with the loading machine structure 1, used to drive the loading knot mechanism to slide on the first track 12; the top tightening structure 3, the structure is located in front of the loading structure 3, including the induction system 31 And tighten the slider 32, the induction system 31 is used for positioning and monitoring materials;

[0045] When the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com