Annular light spot optical system for metal SLM printing and printing method

A ring-shaped spot and optical system technology, applied in the field of ring-shaped spot optical system, can solve the problems of rapid heating and cooling, affecting the performance of finished products, excessive energy concentration, etc., to achieve better printing effect contrast, ensure mechanical properties, and avoid defects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be noted that the specific embodiments and accompanying drawings are not intended to limit the scope of rights of the present invention.

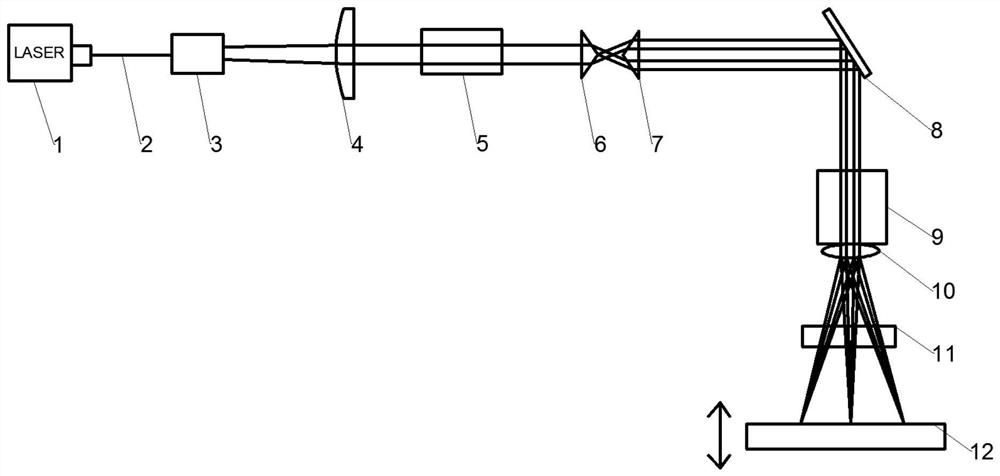

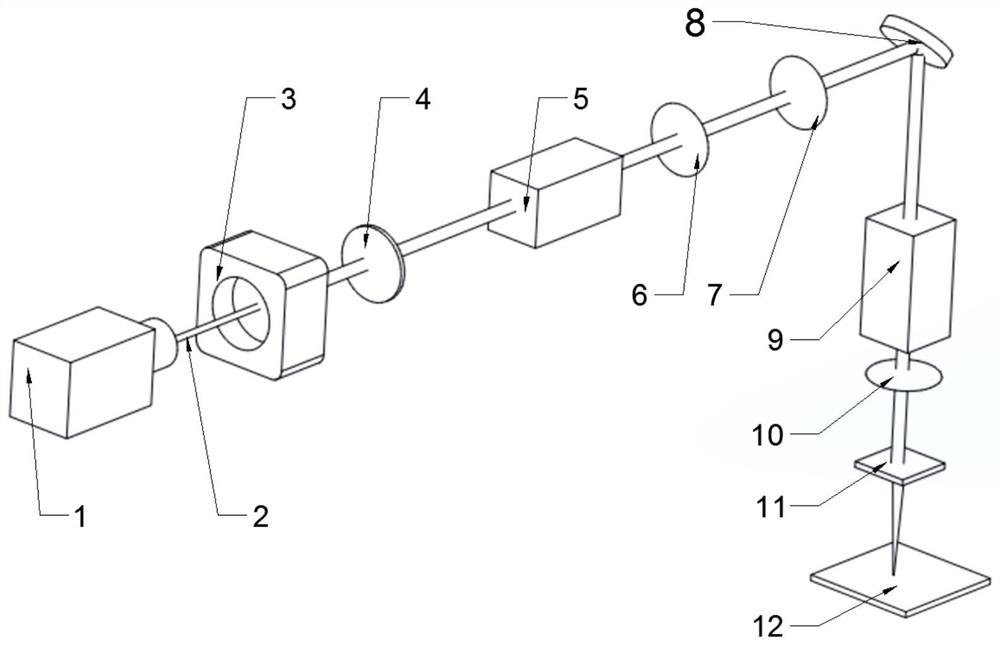

[0030] Such as Figure 1 to Figure 6As shown, the annular spot optical system for metal SLM printing in this specific embodiment includes a laser 1, a collimator 4, a variable magnification beam expander 5, A beam shaping unit, a total reflection mirror 8 , a galvanometer system 9 , a field mirror 10 , a beam quality analyzer 11 and a working platform 12 .

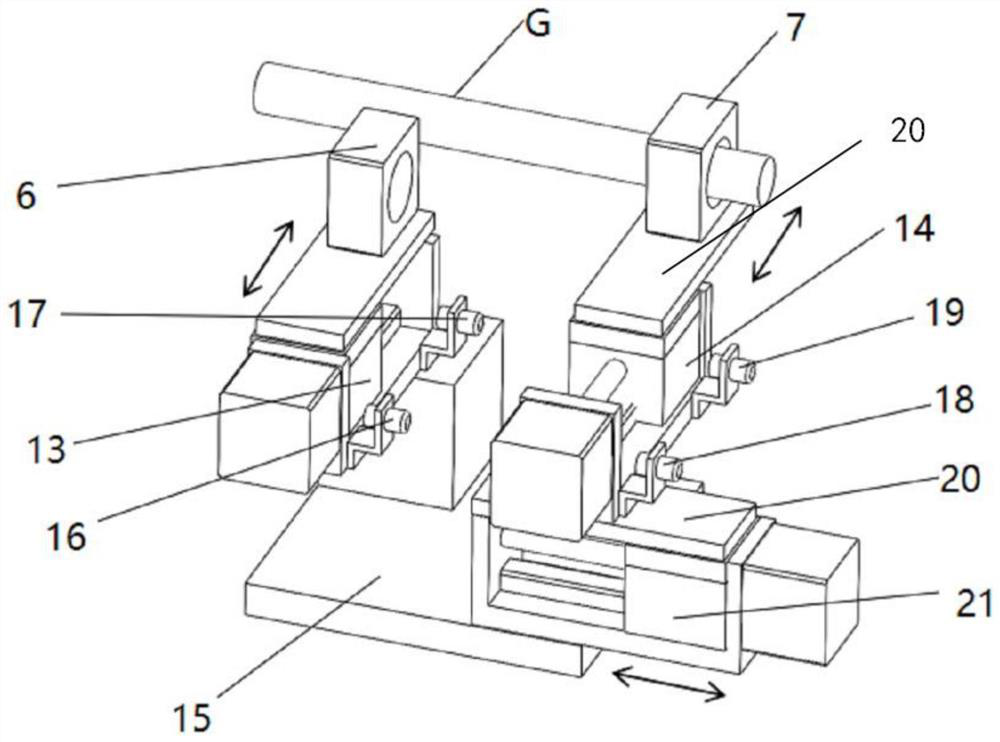

[0031] The beam shaping unit of this specific embodiment is set in the metal SLM printer, and the overall optimization of the processing method of the parts is carried out in cooperation with the path planning of the printer equipment. The beam shaping unit includes a first conical lens 6, a second conical lens 7 and an electric switch...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap