Precision casting sand blasting device

A sandblasting device and technology for precision castings, applied in the direction of explosion generating devices, used abrasive processing devices, spray guns, etc., can solve the inconvenience of precision castings for sandblasting, inconsistent sandblasting and polishing, and stable manual holding Poor performance and other problems, to achieve the effect of facilitating comprehensive sandblasting, improving sandblasting efficiency, and increasing practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

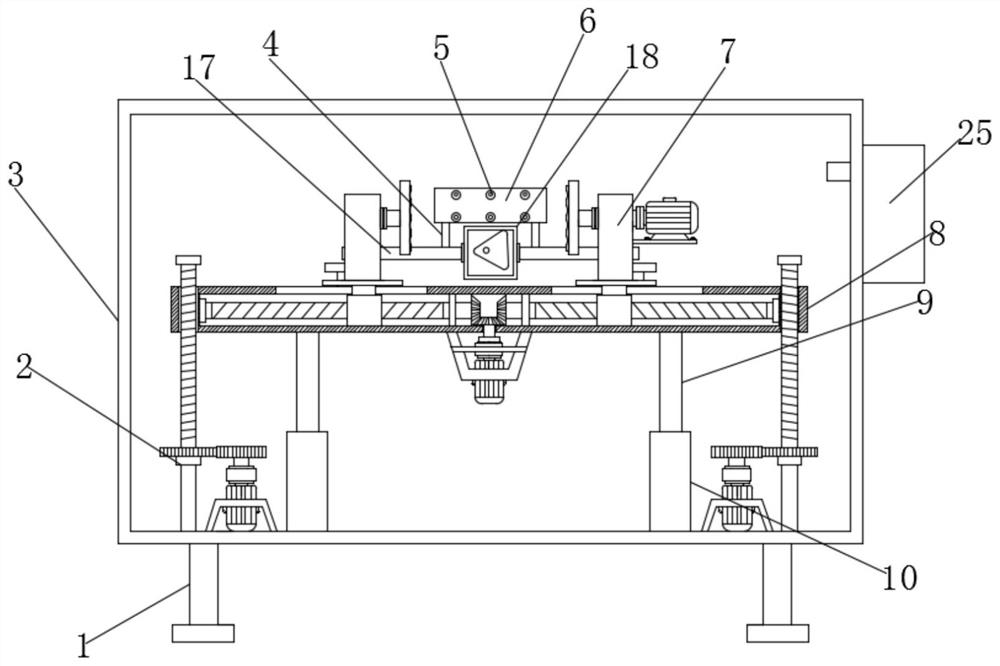

[0032] A sandblasting device for precision castings, comprising a sandblasting box 3, the lower end of the sandblasting box 3 is provided with a support leg 1, and a workbench 8 is arranged inside the sandblasting box 3, and both sides of the lower end of the workbench 8 are provided with lifting mechanisms 2;

[0033] Lifting mechanism 2 comprises the first electric motor 205 that is fixed on the inner bottom of sandblasting box 3, and the output end of first electric motor 205 is provided with second gear 204, and the outside of second gear 204 is provided with the first gear 203 of meshing connection, the first The middle of the gear 203 is provided with a first threaded rod 201, and the upper end of the first threaded rod 201 runs through the workbench 8 to be provided with a fixed block 202, and the first threaded rod 201 is threadedly connected with the workbench 8; the lower end of the workbench 8 is provided with a limit rod 9. A sleeve 10 is arranged on the outside of...

Embodiment 2

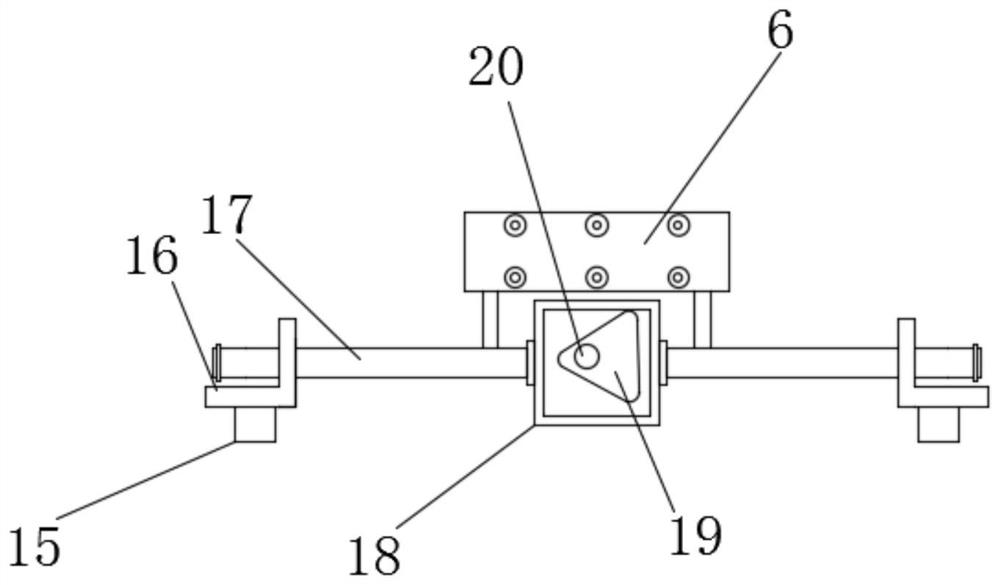

[0036] As an option, see figure 1 , Figure 5-6 , a sandblasting device for precision castings, a clamping mechanism 7 is arranged above the workbench 8;

[0037]The clamping mechanism 7 includes two groups of moving seats 707 arranged on the top of the workbench 8. The inner sides of the two groups of moving seats 707 are provided with clamping plates 703. Pad 23; the lower ends of the two groups of moving seats 707 are provided with a fixed plate 702, the lower end of the fixed plate 702 is provided with a moving block 701, the moving block 701 is arranged on the inside of the workbench 8, and the inner thread of the moving block 701 is connected with a second threaded rod 704, the second threaded rod 704 is provided with two groups, and the direction is oppositely arranged, and one end of the second threaded rod 704 is all rotatably connected on the inner wall of the workbench 8, and the other end of the second threaded rod 704 is provided with the first bevel gear 705 Th...

Embodiment 3

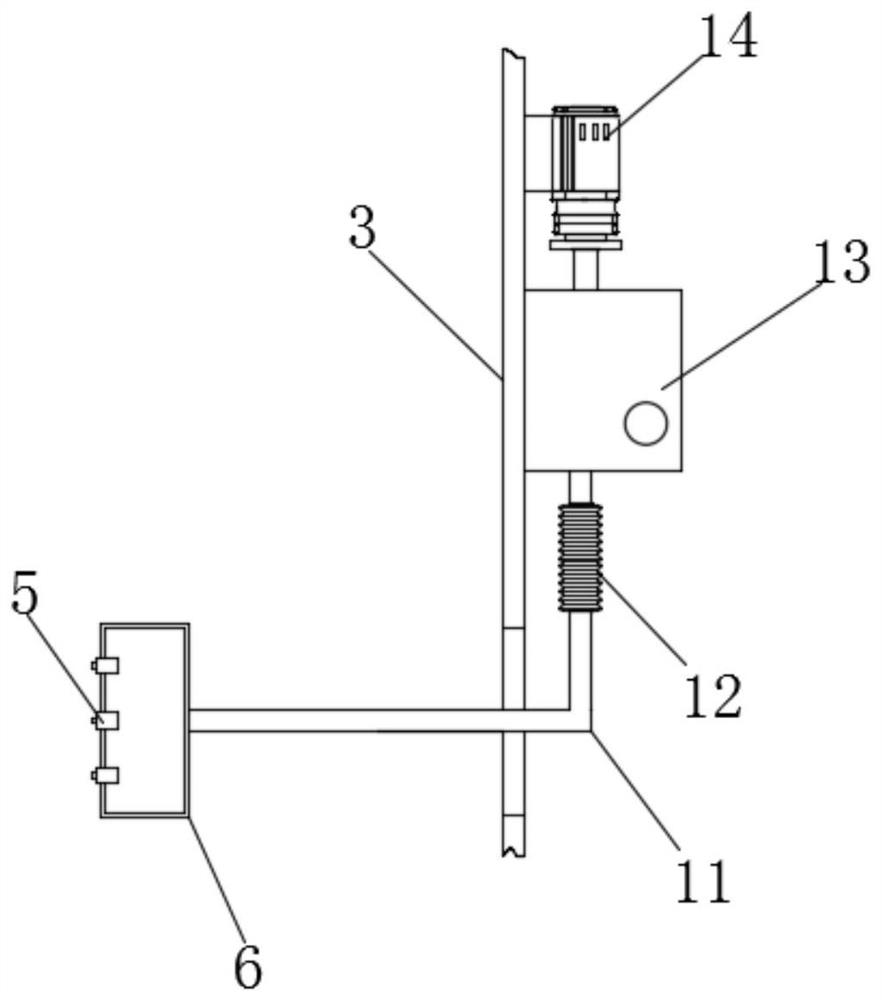

[0041] As an option, see Figure 1-4 , a sandblasting device for precision castings, a sandblasting box 6 is arranged on the top of the workbench 8, a plurality of groups of nozzles 5 are arranged on the surface of the sandblasting box 6, and one end of a connecting pipe 11 is arranged on the rear side of the sandblasting box 6, and the connecting pipe 11 The other end is connected with elastic bellows 12, and one end of elastic bellows 12 is connected with sand material box 13, and sand material box 13 is fixed on the outside of sandblasting box 3, and one side of sand material box 13 is provided with air pump 14, sandblasting box The lower end of 6 is provided with fixed rod 4, and the lower end of fixed rod 4 is provided with sliding rod 17, and the middle of sliding rod 17 is provided with frame plate 18, and the inside of frame plate 18 is provided with turning block 19, in order to drive sandblasting box 6 reciprocating Movement, the turning block 19 is set as a triangul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com