Manufacturing process of wind turbine blade

A wind turbine blade and manufacturing process technology, which is applied to other household appliances, household appliances, household components, etc., can solve problems such as glue accumulation, long production time, and affecting the quality of wind turbine blades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

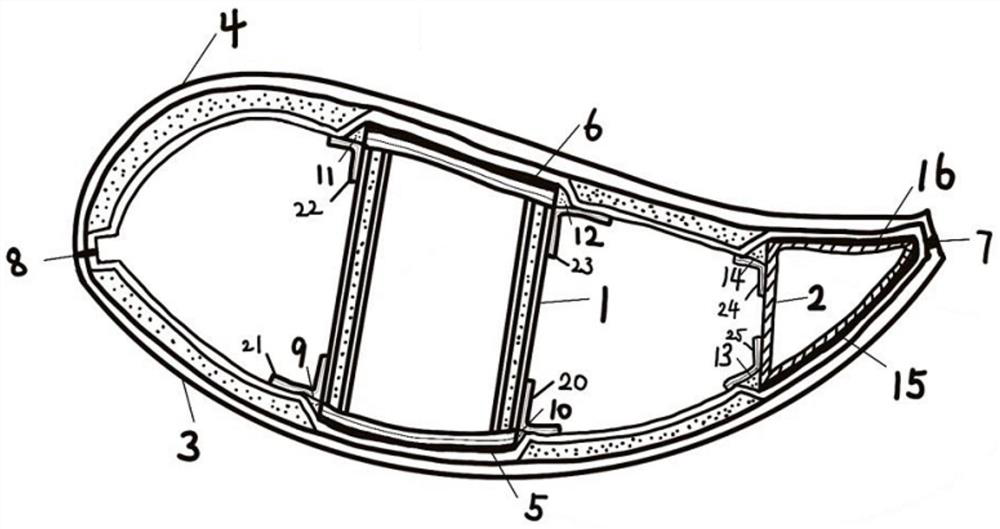

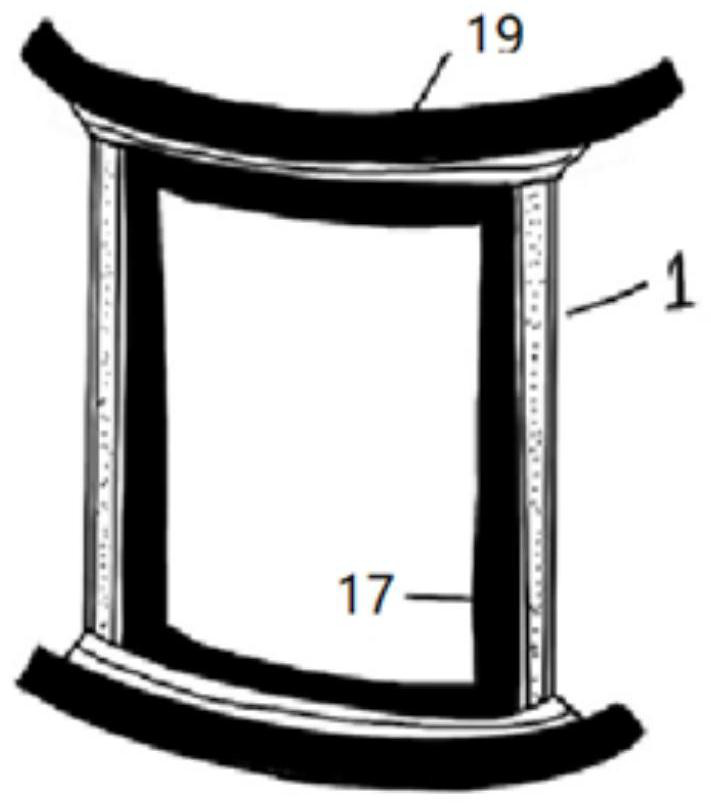

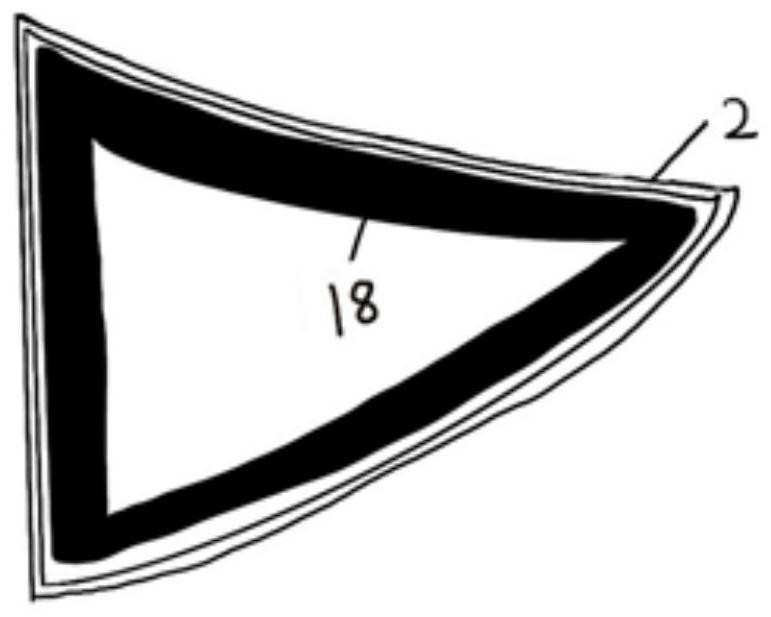

[0036] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0037] A manufacturing process of a wind turbine blade, comprising the following steps:

[0038] S1: Design the box-shaped main girder web mold 17, the small web trailing edge beam mold 18 and the blade shell mold according to the structure of the wind turbine blade;

[0039] S2: Make box-shaped main girder web 1, small web trailing edge beam 2 and blade shell respectively in box-type main girder web mold 17, small web trailing edge beam mold 18 and blade shell mould;

[0040] S3: Install the box-shaped main girder web 1 and the small web trailing edge girder 2 in the blade shell.

[0041] The blade shell in this embodiment includes a SS surface shell 3 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com