Blade root end pouring device for wind mill

A wind turbine blade and root end technology is applied in the field of wind turbine blade root end pouring devices, which can solve the problems of high technical difficulty, complex control parameters, long pouring process time, etc., so as to improve the density, improve product quality, and improve pouring speed. and the effect of quality stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

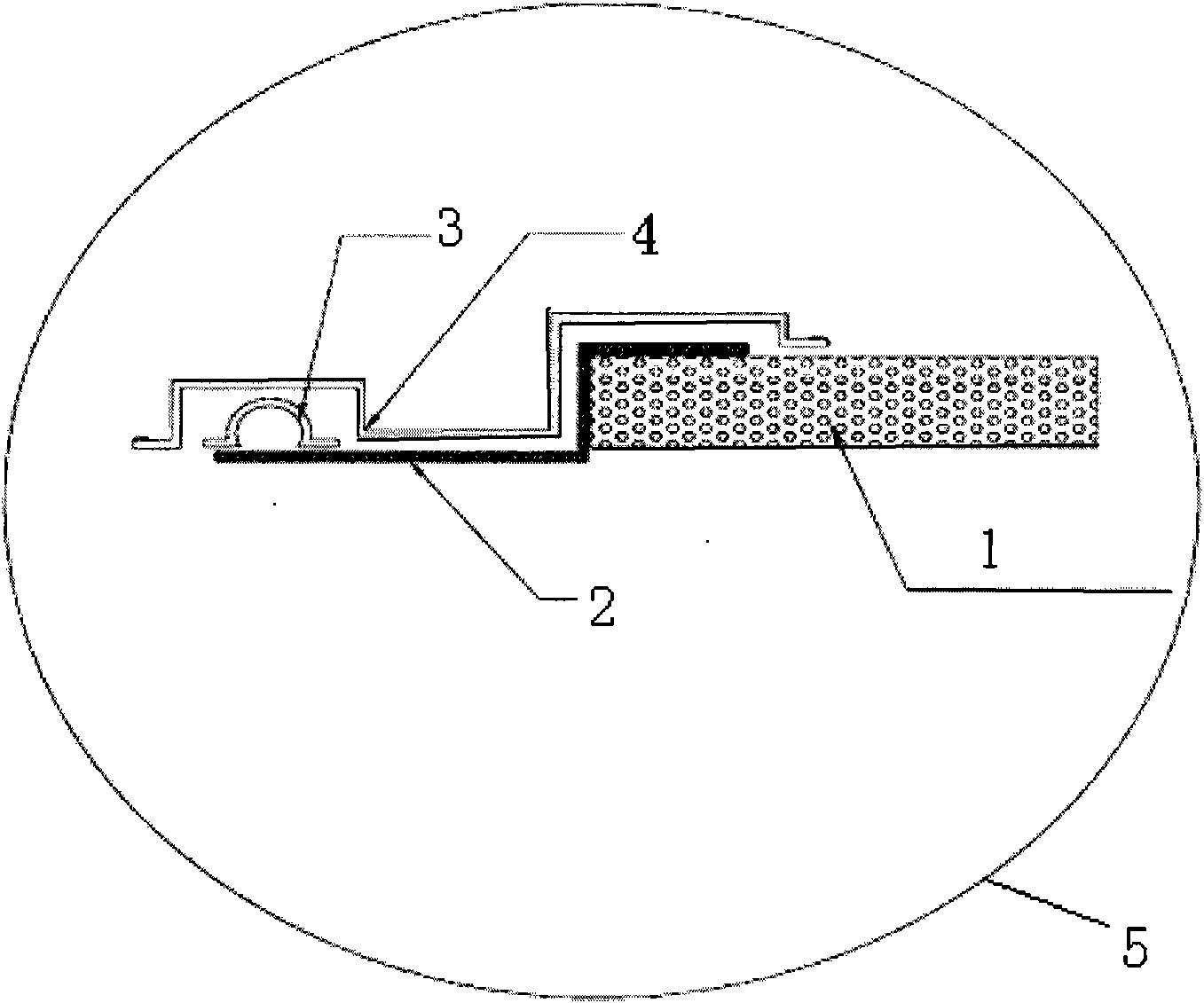

[0010] Depend on figure 1 It can be seen that the present invention includes: a root-end structure lay-up 1; a diversion net 2 is arranged at the front end of the root-end structure lay-up 1, and a resin diversion pipe 3 is placed on the upper front end of the diversion net 2; it also includes: A breathable isolation film 4; said breathable isolation film 4 is covered on the guide net 2, and between the outlet of the resin guide pipe 3 to the front side of the root-end structural layup 1; a vacuum pumping mechanism 5 ; The root-end structure lay-up 1 , guide net 2 , resin guide tube 3 and breathable isolation membrane 4 are in the vacuum pumping mechanism 5 .

[0011] The working process of the present invention is: after the perfusion starts, the resin first starts to flow in the diversion tube, and flows into the root-end structure layer thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com