Automatic quantitative packaging equipment

A kind of packaging equipment and automatic technology, applied in the direction of packaging automatic control, packaging, transportation packaging, etc., can solve the problems of low automation, low work efficiency, inaccurate feeding volume, etc., to improve production efficiency, improve practicability, and reliable structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

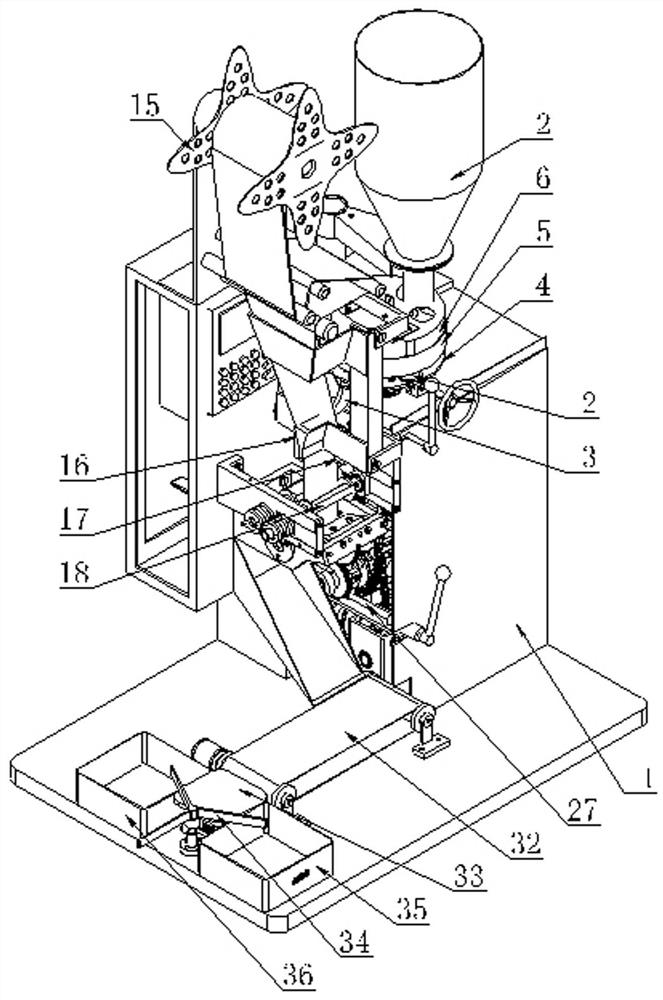

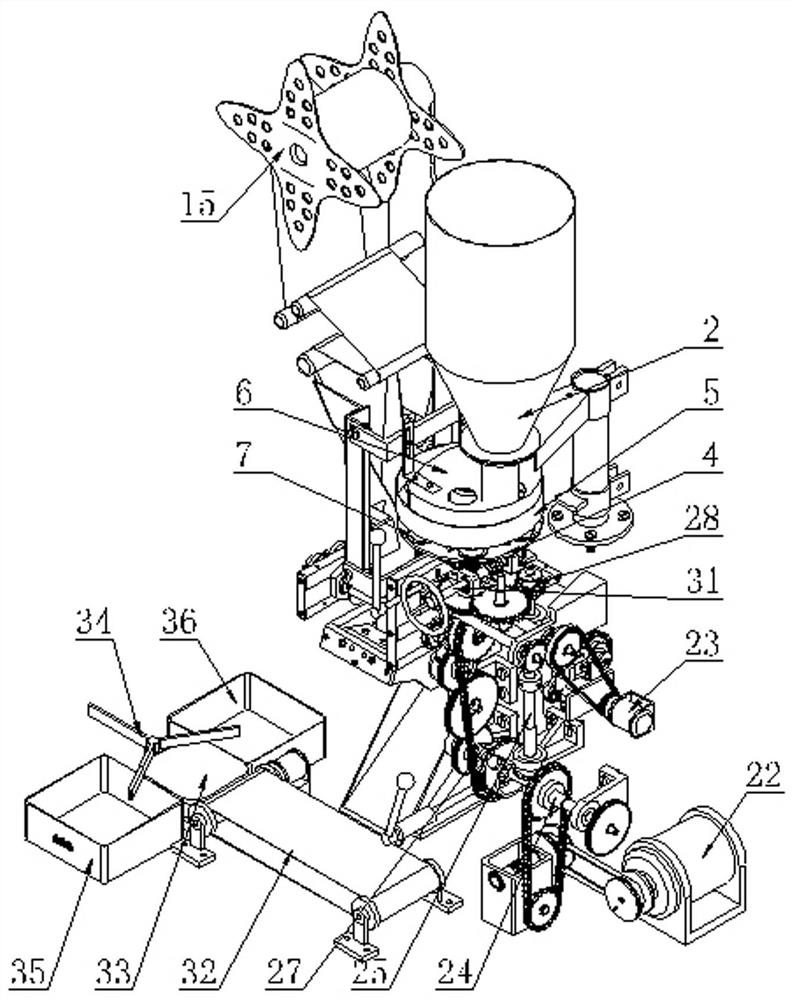

[0049] Such as Figure 1-18 As shown, an automatic quantitative packaging equipment includes a casing 1, a packaging assembly is arranged on the upper part of the casing 1, a packaging assembly is arranged on the outside of the casing 1, a power assembly is arranged inside the casing 1, and the power assembly is connected to the packaging assembly and the packaging assembly. ;

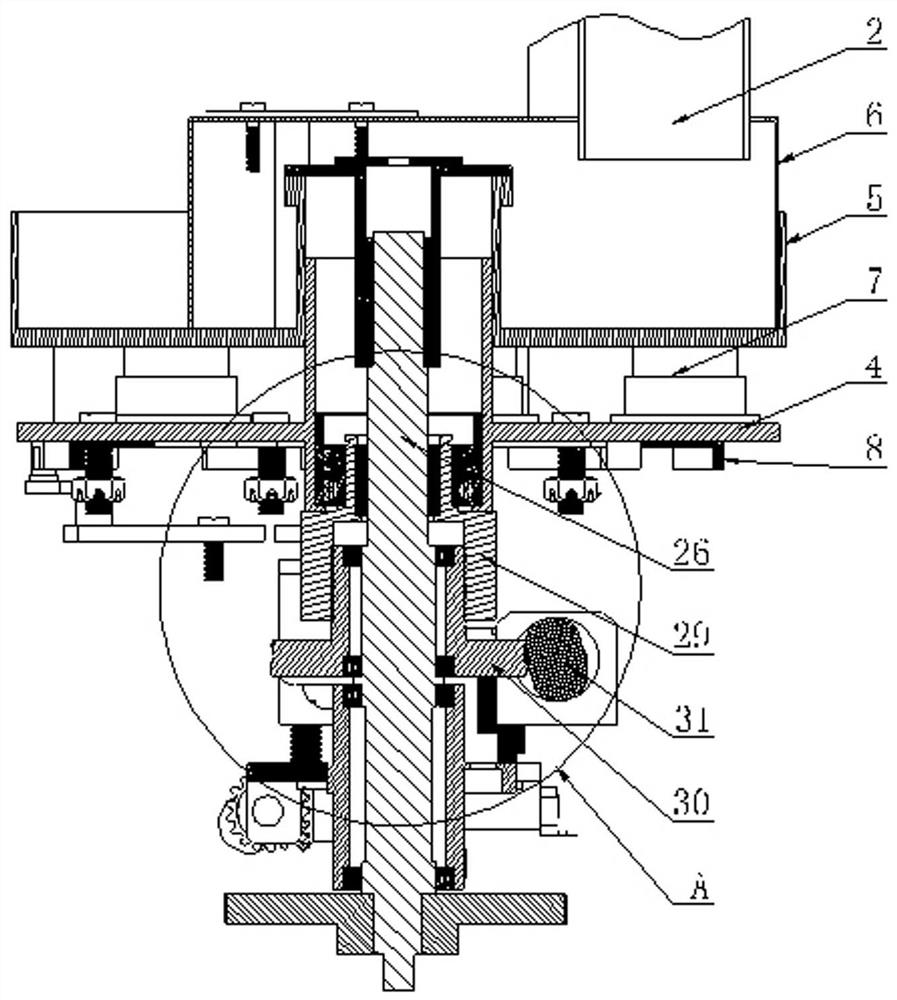

[0050] The dispensing assembly includes a feeding hopper 2, a feeding pipe 3, a turntable 4, a lower storage bin 5, an upper storage bin 6 and a distributing mechanism. 5 is in the shape of a cylinder with an open upper end, and the turntable 4 is coaxially arranged below the lower storage bin 5, and several storage barrels 7 are arranged in a circular array between the turntable 4 and the lower storage bin 5, and the upper and lower ends of the storage barrel 7 are They are fixedly connected to the lower storage bin 5 and the turntable 4 respectively. The upper storage bin 6 is fixedly arranged on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com