Sweeping roller and belt conveyor

A belt conveyor and cleaning roller technology, which is applied to conveyor objects, cleaning devices, transportation and packaging, etc., can solve problems such as poor cleaning effect, improve cleaning effect, improve dust situation, and reduce re-adhesion. The effect of the odds on the conveyor belt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

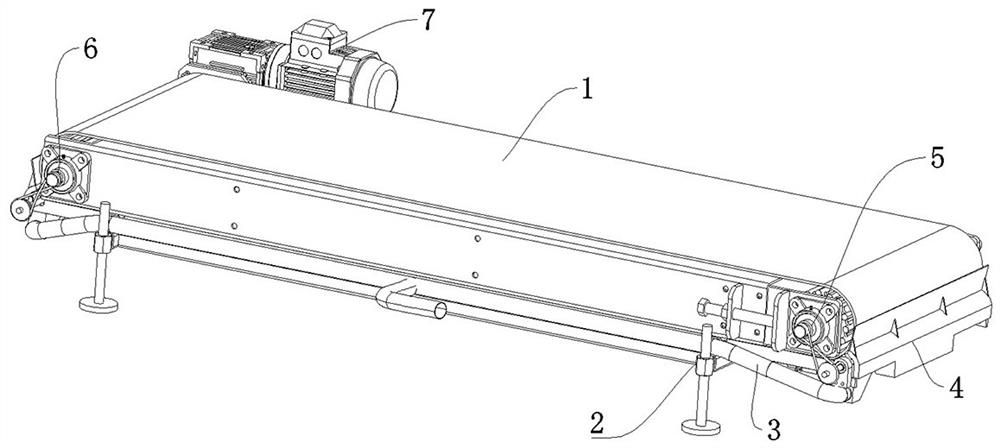

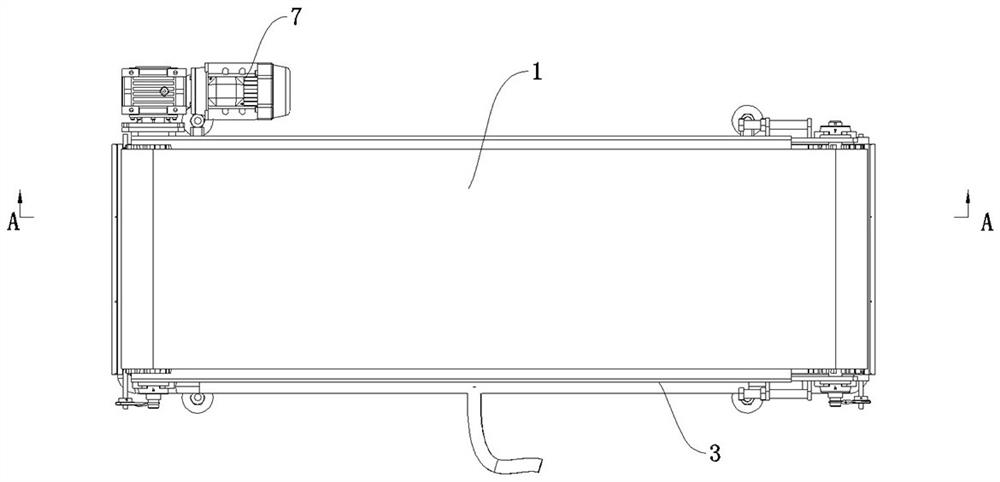

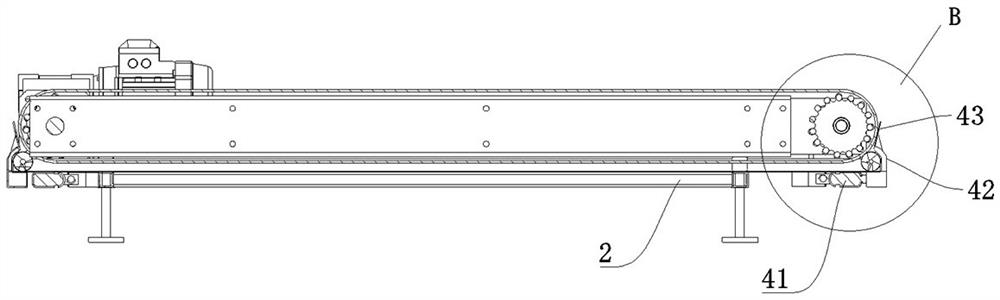

[0052] like Figure 1 to Figure 6 As shown, the belt conveyor in this embodiment can be used for conveying valve pockets. Corresponding to the conveying belt 1, a cleaning powder collecting device is configured to clean the dust on the conveying belt 1. The cleaning roller 10 of the cleaning powder collecting device is not only provided with There is a brush 102 and a single-rotation spiral conveying blade 103. In this way, the surface of the conveying belt 1 is swept by the brush 102, and the brushed dust is conveyed by the spiral conveying blade 103 to the dust collector of the cleaning roller 10. In this way, the dust that has been swept is transported in one direction by the screw conveying blade 103 in a centralized manner, and will not be scattered everywhere, which effectively improves the dust collection efficiency.

[0053] like Figure 1 to Figure 6 As shown, the belt conveyor in this embodiment includes a conveyor frame body 2, the conveyor frame body 2 extends in ...

specific Embodiment 2

[0065] The main difference between it and Example 1 is that: in Example 1, the rotation direction of the cleaning roller is opposite to the rotation direction of the conveying belt, and the cleaning can be reversed to improve the cleaning effect. In this embodiment, the rotation direction of the cleaning roller can also be consistent with the rotation direction of the conveying belt.

specific Embodiment 3

[0067] The main difference from Example 1 is that in Example 1, when the corresponding belt roller drives the cleaning roller to rotate through the belt drive mechanism, a figure-eight belt is used, so that the rotation direction of the cleaning roller is opposite to the rotation direction of the conveying belt. In this implementation, a motor can be separately configured for each cleaning roller, and the cleaning roller is directly driven by the motor to rotate in the forward direction or in the reverse direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com