Lignin nanoparticle/polyvinyl alcohol/chitosan ternary composite material as well as preparation method and application thereof

A technology of nano-particles and polyvinyl alcohol, which is applied in paper coating, textile and paper making, fiber raw material processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] A kind of preparation method of lignin nanoparticle (LNP) of the present embodiment, described method specifically comprises the steps:

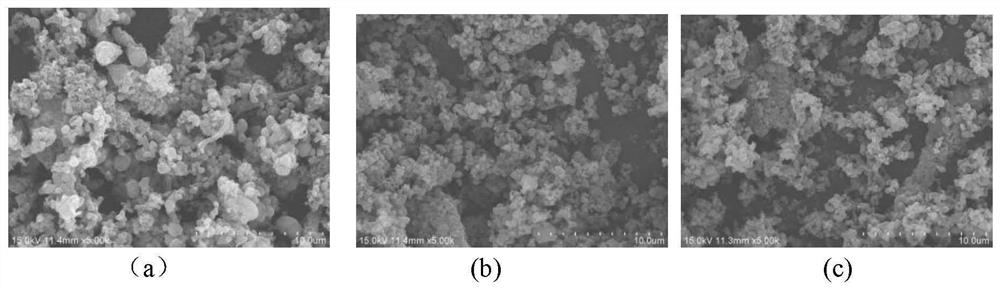

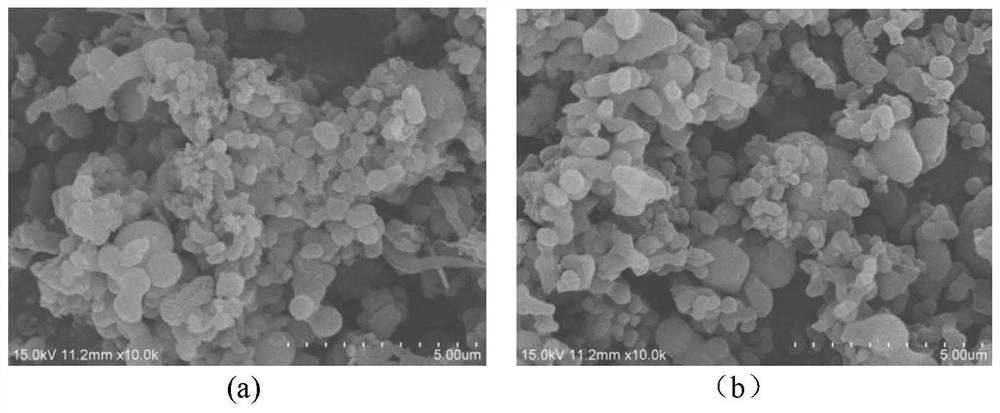

[0057] Dissolve 1.5 g of lignin in 10 mL of ethanol solvent to obtain a lignin ethanol solution; slowly add 10 mL of HCl solution with a concentration of 0.1 mol / L to the lignin ethanol solution at a rate of 1 drop / min , stand at room temperature for 2 hours; use Whatman 541 filter paper (pore size 0.22 μm) to filter; then use MD55 dialysis bag to dialyze in deionized water for 3 days, and dilute the solution in the dialysis bag to 400mL aqueous solution after dialysis; After a few days, when the lignin in the solution is deposited on the bottom, take out the lignin at the bottom, and bake the obtained lignin in an oven at 40-60°C for 24 hours by thermal evaporation, take it out, place it in a petri dish, put it in freezing the freezing layer of the refrigerator for half an hour to 1 hour, and finally putting the petri dish containing...

Embodiment 2-3

[0060] The preparation method of the lignin nanoparticles (LNP) in Example 2-3 is the same as that in Example 1, the only difference being that the dropping rate of the HCl solution in Example 2-3 is 2 drops / min and 10 drops / min.

Embodiment 4

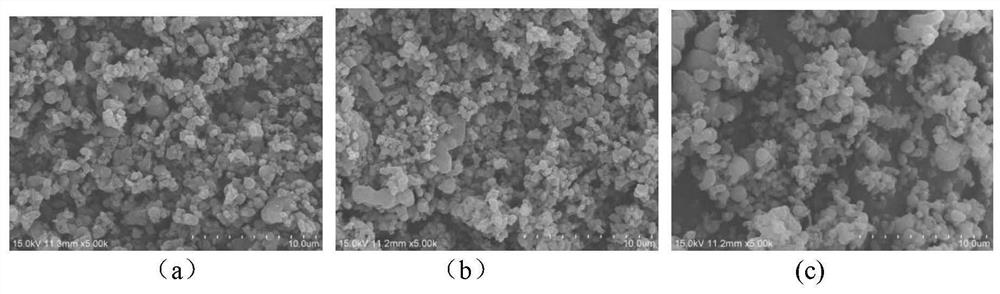

[0062] The preparation method of the lignin nanoparticles (LNP) in Example 4 is the same as that in Example 1, except that the concentration of the HCl solution in Example 4 is 0.25 mol / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com