Collation shrink film

A shrink film, range technology, applied in one step to one field, can solve the problems such as the risk of increasing the formation of holes due to the non-uniformity of pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

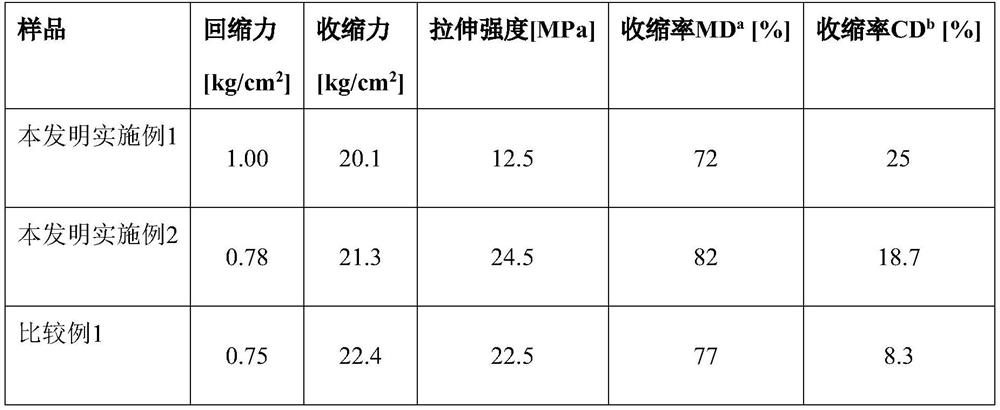

Image

Examples

Embodiment Construction

[0018] definition:

[0019] In the gist of the present invention, the term "multimodal" may mean multimodal with respect to the molecular weight distribution and thus also include bimodal polymers. However, as explained in the detailed description of the components, the components may also be multimodal with respect to other properties, such as MFR or density.

[0020] Generally, a polymer composition comprising at least two polyethylene fractions produced under different polymerization conditions resulting in different (weight average) molecular weights of the fractions is said to be "multimodal". and molecular weight distribution. The prefix "multiple" relates to the number of different polymer fractions present in the polymer. Thus, for example, the term multimodal polymer includes so-called "bimodal" polymers consisting of two fractions. The form of the molecular weight distribution curve for a multimodal polymer such as LLDPE, i.e. the appearance of a plot of the polym...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com