Particle manufacturing machine capable of converting waste into agricultural fertilizer

A manufacturing machine and agricultural technology, which is applied in the field of pellet manufacturing machines, can solve the problems of different sizes, poor product use effects, and reduced fertilizer use effects, etc., to achieve the effects of maintaining uniformity, preventing clogging, and increasing extrusion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

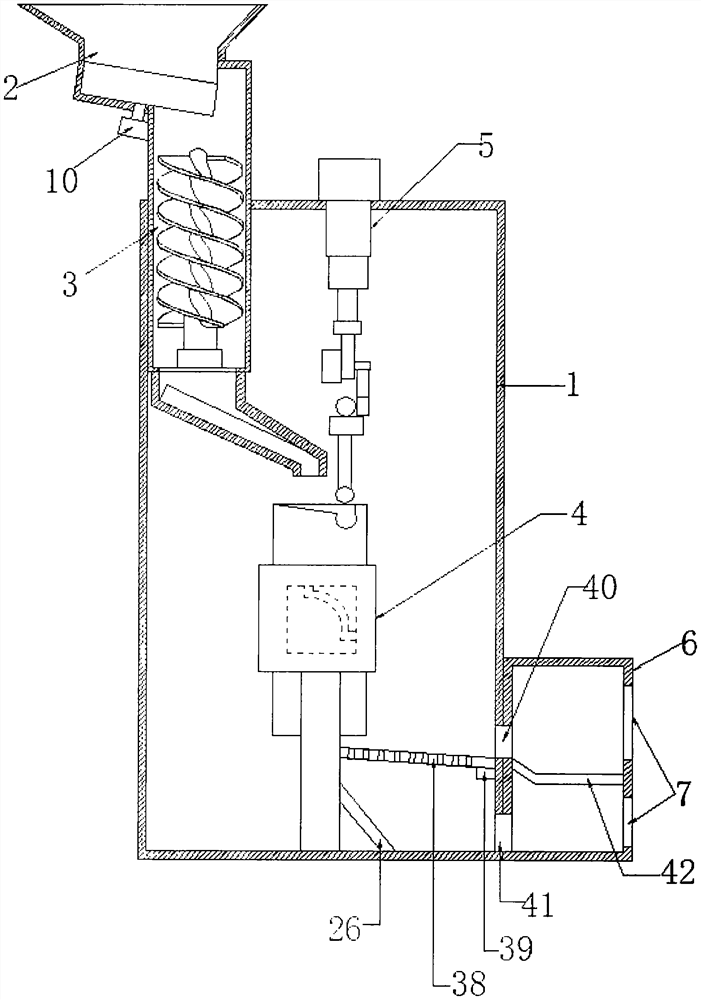

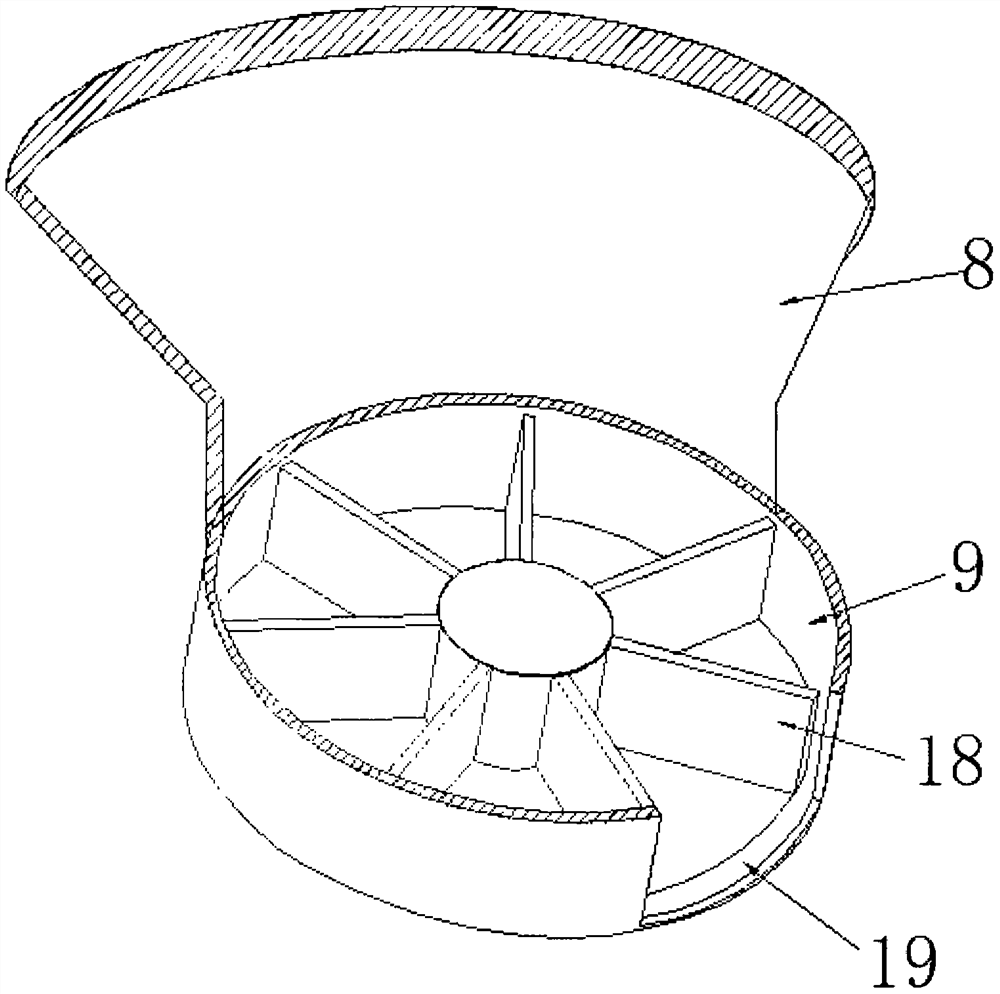

[0037] Such as Figure 1-6 displayed in:

[0038] The invention provides a granule manufacturing machine capable of converting waste materials into agricultural fertilizers, comprising an operation box 1, a blanking part 2 is provided on the top side of the operation box 1, and a blanking part 2 is provided below the blanking part 2. There is a feeding part 3, the feeding part 3 runs through the operation box body 1 and extends to the upper side of the operation box body 1, and an operation part 4 is arranged below, and an extruding part is arranged above the operation part 4 5. The extruding part 5 is installed at the top center of the operation box 1, and the bottom of the operation box 1 and the side away from the blanking part 2 is provided with a collection box 6, and the collection box 6 And the upper and lower parts of the side away from the operation box 1 are provided with a discharge cover 7, and the center of the front of the operation box 1 is provided with an obs...

Embodiment 2

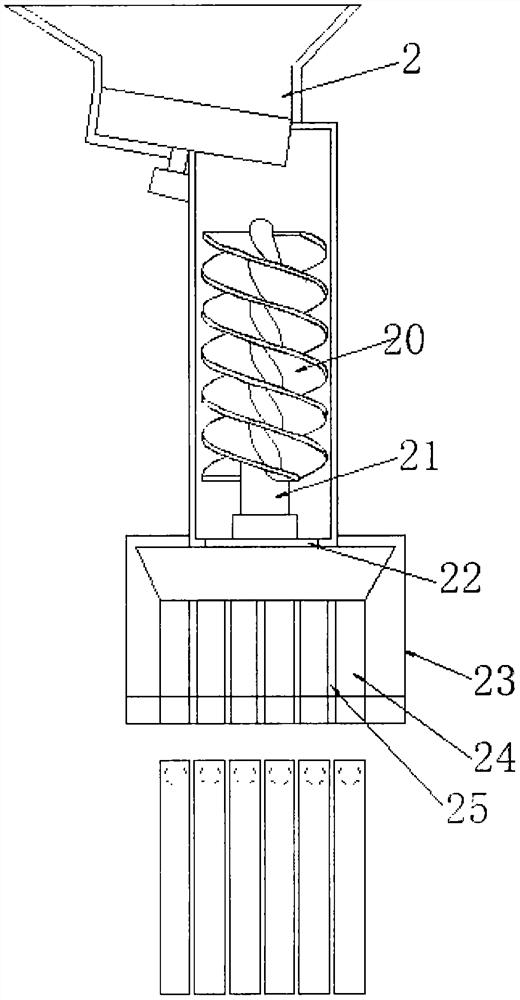

[0042] Such as Figure 7-10 displayed in:

[0043] The invention provides a granule manufacturing machine capable of converting waste materials into agricultural fertilizers, comprising an operation box 1, a blanking part 2 is provided on the top side of the operation box 1, and a blanking part 2 is provided below the blanking part 2. There is a feeding part 3, the feeding part 3 runs through the operation box body 1 and extends to the upper side of the operation box body 1, and an operation part 4 is arranged below, and an extruding part is arranged above the operation part 4 5. The extruding part 5 is installed at the top center of the operation box 1, and the bottom of the operation box 1 and the side away from the blanking part 2 is provided with a collection box 6, and the collection box 6 And the upper and lower parts of the side away from the operation box 1 are provided with a discharge cover 7, and the center of the front of the operation box 1 is provided with an ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com