End connecting device of plate spring, mounting method of end connecting device and end deformation method of plate spring

An end connection, leaf spring technology, applied in the lateral relative movement device between the chassis and the bogie, non-rotational vibration suppression and other directions, can solve the problem of easy wear, poor reliability, roll ears and composite material leaf springs Forming difficulty and other problems, to achieve the effect of increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following is attached Figure 1-5 The present invention is further described in detail.

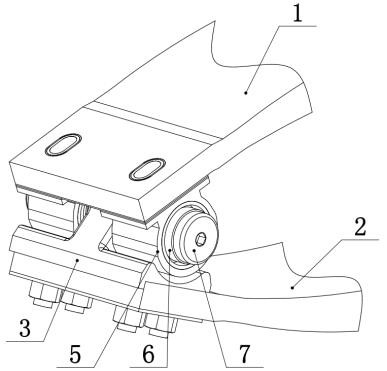

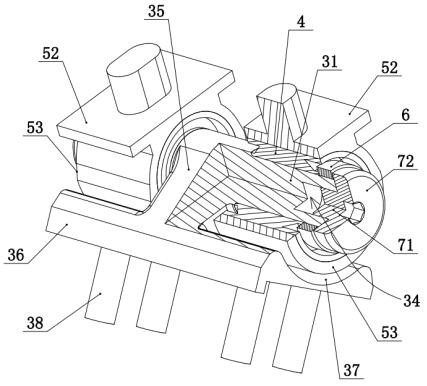

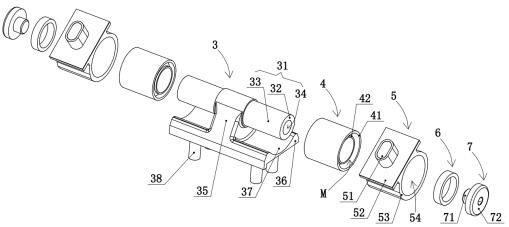

[0034]The end connection device of the leaf spring, wherein the leaf spring includes two upper and lower semi-elliptical spring leaves, which are respectively the upper spring leaf 1 and the lower spring leaf 2, and the leaf spring is formed by pairing the upper spring leaf 1 and the lower spring leaf 2 to form an ellipse Shaped leaf spring. The end connecting device of the plate spring comprises an upper metal sleeve 5 and a lower metal seat 3 connected between the ends of the upper spring leaf 1 and the lower spring leaf 2, the upper metal sleeve 5 is fixed on the lower metal seat 3 and the upper metal There is a rubber bushing 4 between the sleeve 5 and the lower metal seat 3, and the deformation of the rubber bushing 4 is used to meet the longitudinal displacement between the upper spring piece 1 and the lower spring piece 2 when bearing the load and make the upper spring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com