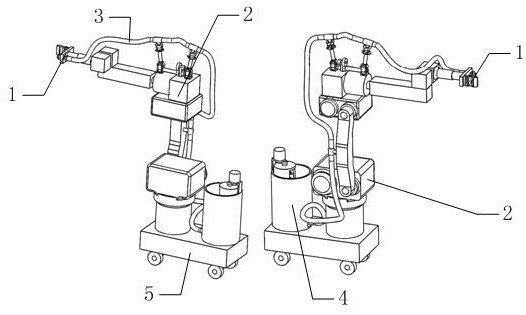

Intelligent clamping and laying equipment for practical training of students

A practical and intelligent technology, applied in the field of plastering, can solve problems such as waste of raw materials, waste of materials, and mechanical failure of dirty equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

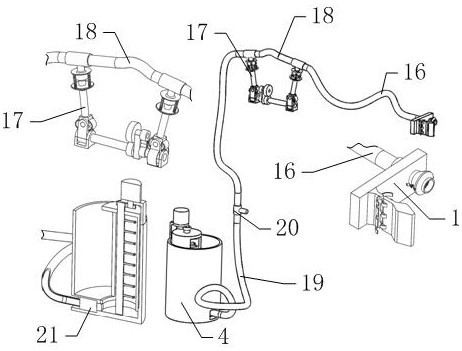

Method used

Image

Examples

Embodiment approach

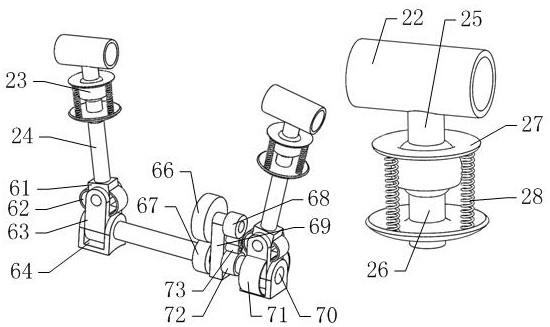

[0082]Implementation mode: when using the equipment designed in the present invention to scrape walls, control the second motor 75 to work, the second motor 75 will drive the sixth gear 76 to rotate, the sixth gear 76 will drive the seventh gear 77 to rotate, the seventh The rotation of the gear 77 drives the rotation of the installation rod 79, and the rotation of the installation rod 79 drives the rotation of the rotating shell 74. At the same time, the rotation of the installation rod 79 drives the rotation of the fixed rod 83 installed on it, and then drives the rotation of the second steady flow shell 84 thereon; through the rotation of the rotation shell 74 The rotation can stir the air bubbles in the paint entering the rotating shell 74 to reduce the distribution of the air bubbles; at the same time, the second steady flow shell 84 installed on the mounting rod 79 can absorb the air bubbles in the paint.

[0083] Then the paint is sprayed into a part of the wall through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com