Alternating current line poor contact fault monitoring device

A poor contact and fault monitoring technology, applied in the direction of measuring devices, measuring electricity, measuring electrical variables, etc., can solve problems such as poor line contact, increased node resistance, and large voltage drop, and achieve the effect of improving power production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

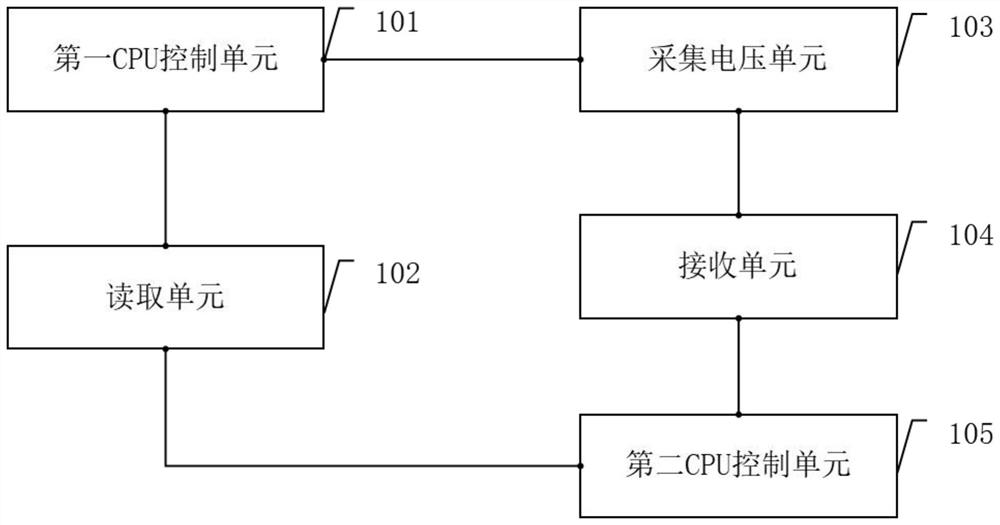

[0021] Such as figure 1 and image 3 As shown, the AC line poor contact fault monitoring device includes: a first CPU control unit 101, a reading unit 102, an acquisition voltage unit 103, a receiving unit 104 and a second CPU control unit 105; the first CPU control unit 101 and the reading unit The unit 102 is coupled; the reading unit 102 is coupled with the collection voltage unit 103; the collection voltage unit 103 is coupled with the receiving unit 104; the reception unit 104 is coupled with the second CPU control unit 105; the collection voltage unit 103 collects voltage data and sends the voltage data to The receiving unit 104, the receiving unit 104 sends the voltage data to the second CPU control unit 105; the second CPU control unit 105 calculates the line resistance according to the voltage, and sends the line resistance to the reading unit 102; the reading unit 102 sends the line resistance To the first CPU control unit 101, the first CPU control unit 101 generat...

Embodiment 2

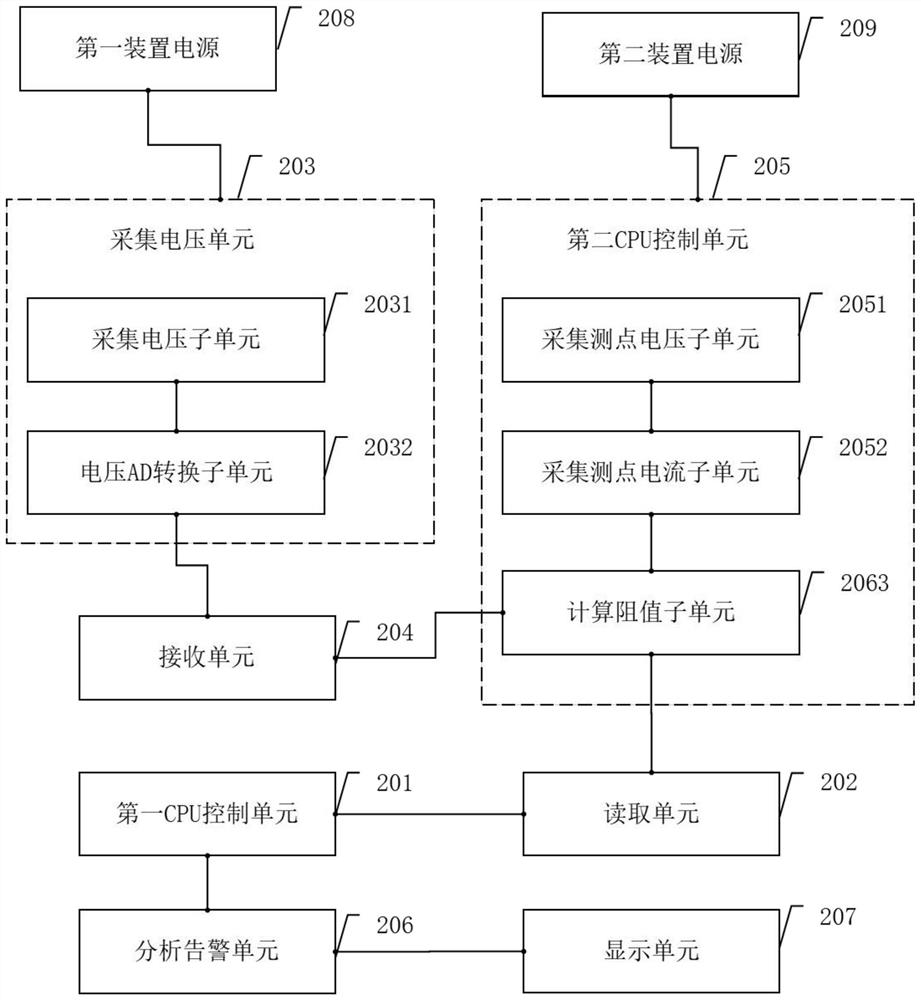

[0028] like figure 2 , image 3 as well as Figure 4 As shown, the AC line fault monitoring device includes: a first CPU control unit 201, a reading unit 202, a voltage collection unit 203, a receiving unit 204, a second CPU control unit 205, an analysis alarm unit 206, a display unit 207, The first device power supply 208, and the second device power supply 209; wherein the second CPU control unit 205 includes: the acquisition measuring point voltage subunit 2051, the acquisition measuring point current subunit 2052 and the calculation resistance value subunit 2053; the acquisition voltage unit 203 includes : the acquisition voltage subunit 2031 and the voltage AD conversion subunit 2031.

[0029] The first CPU control unit 201 is coupled with the reading unit 202; the reading unit 202 is coupled with the acquisition voltage subunit 2031; the acquisition voltage subunit 2031 is coupled with the voltage AD conversion subunit 2032; the voltage AD conversion subunit 2032 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com