Long-distance mud pipeline conveying dynamic model and application

A mud pipeline and long-distance technology, applied in the field of hydraulic transportation, can solve the problems of being unable to simulate the slurry state, unable to study the dynamic characteristics of the slurry in the pipeline, and unable to reflect the dynamic characteristics of the slurry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

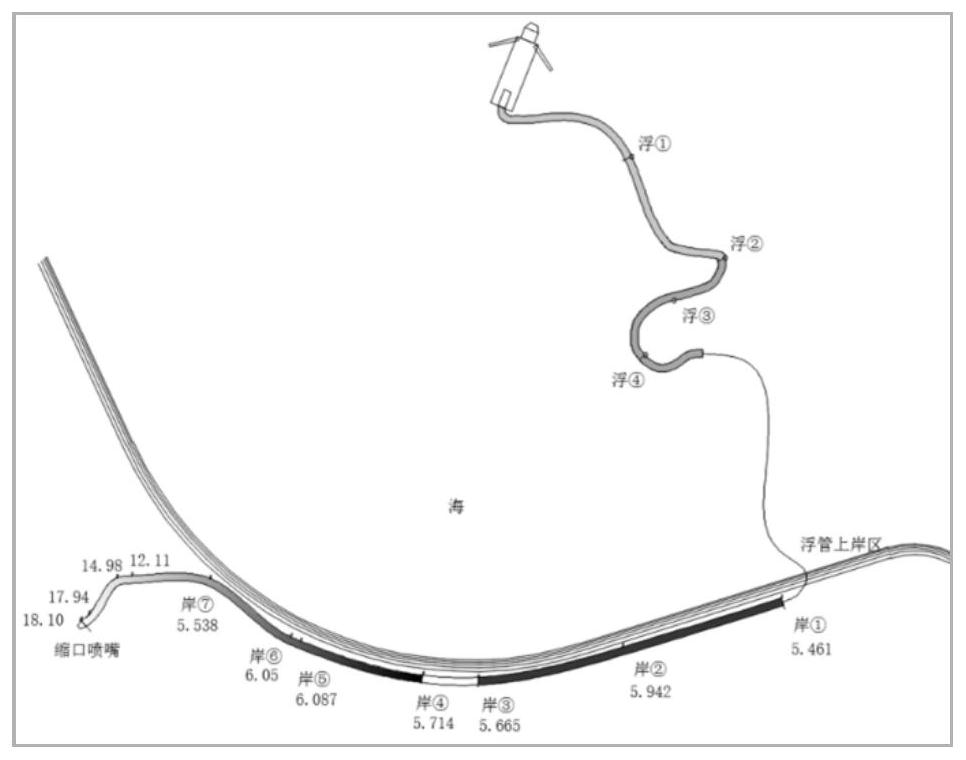

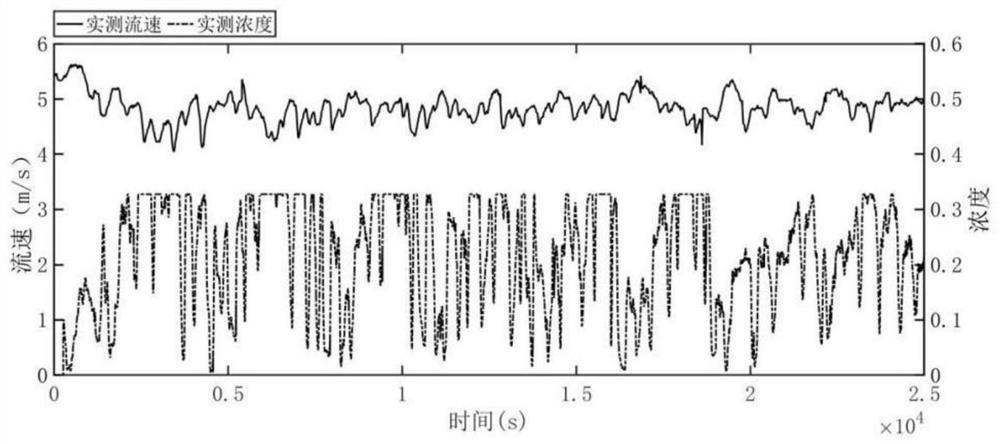

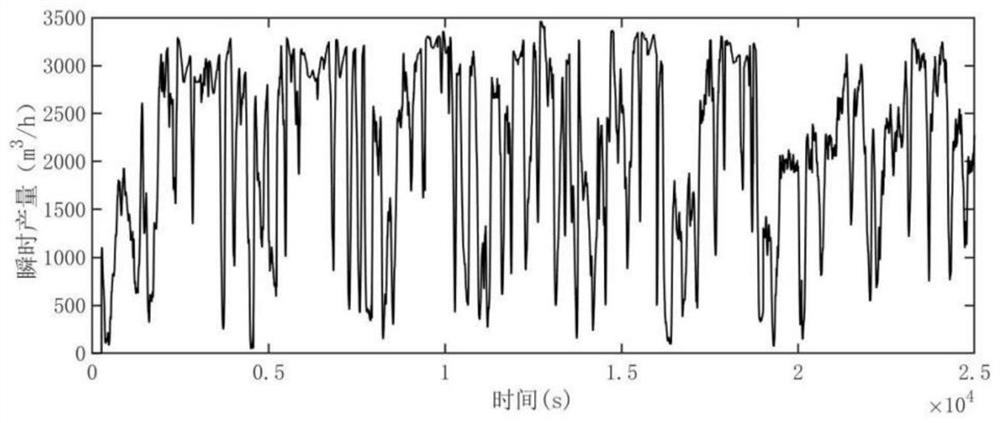

Image

Examples

Embodiment Construction

[0066] The specific implementation will be disclosed in the paper; the technical solution of this application is patentable.

[0067] Theoretical model:

[0068] Select Fei Xiangjun's formula (1994) as the basic formula, modify it through the measured data, and calculate the pipeline friction I m Calculate; the revised Fei Xiangjun formula is as follows:

[0069]

[0070]

[0071]

[0072] In the formula,

[0073] I m Friction loss for conveying slurry (mH 2 O / m); α is the correction coefficient related to the relative viscosity coefficient of the slurry; V ss is the settling velocity of sediment particles;

[0074] λ is the resistance coefficient along the pipeline when transporting clean water; V is the transport velocity (m / s); g is the acceleration of gravity (m / s 2 ); D is the inner diameter of the pipeline (m); γ m is the bulk density of slurry (t / m 3 ); w is the bulk density of the carrier liquid (t / m 3 ); s is the bulk density of solid (t / m 3 ); m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com