Corrosion-resistant shell of high-low voltage switch cabinet

A high and low voltage switch, corrosion-resistant technology, applied in substation/switch layout details, substation/distribution device housing, measuring device, etc. Sex and other issues, to achieve the effect of a stable working area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

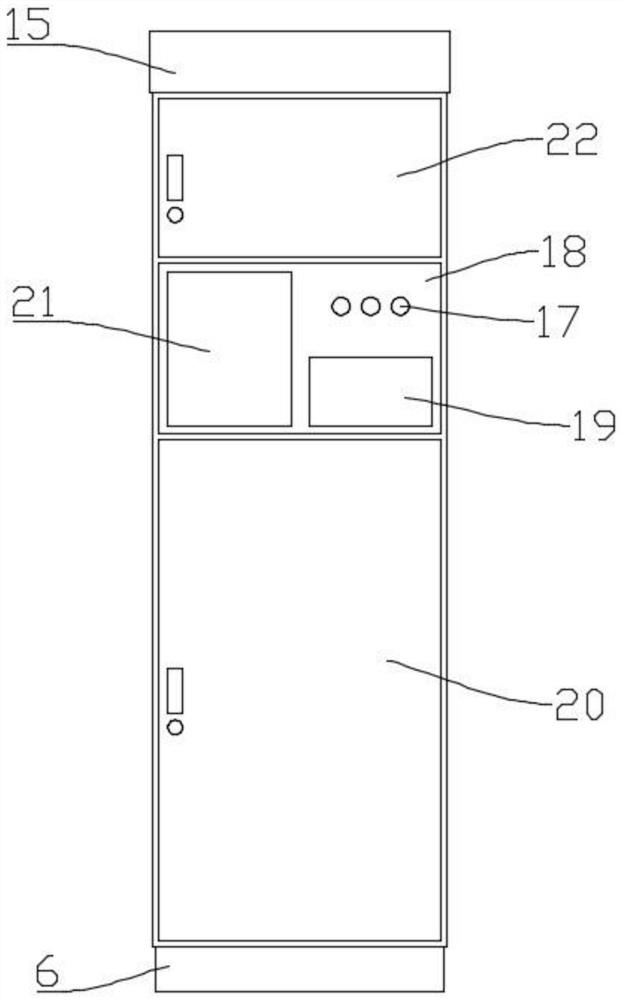

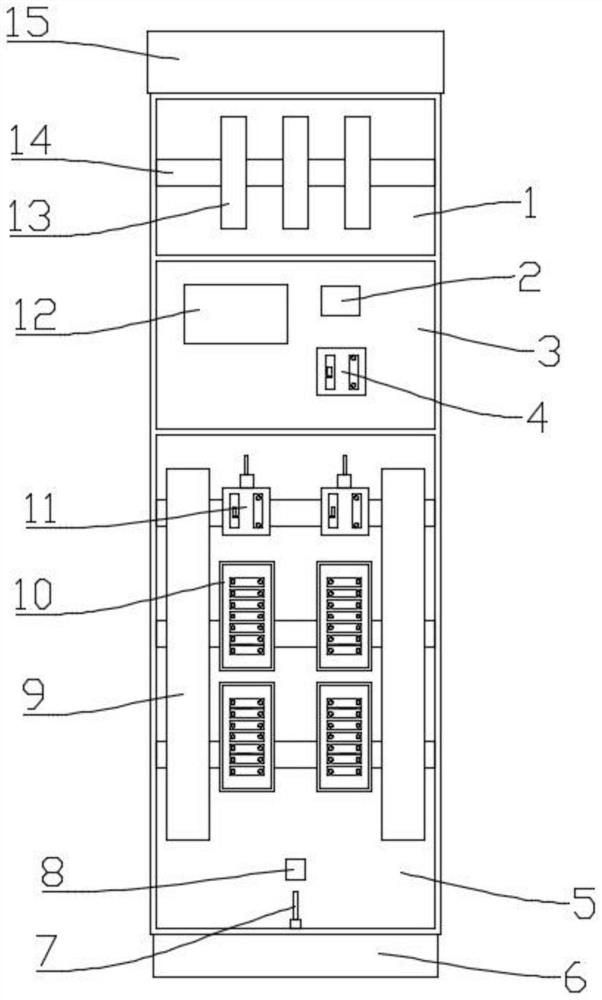

[0027] like Figure 1~6 As shown, a corrosion-resistant shell of a high and low voltage switchgear, a power converter 2, a main switch 4, a base 6, an electrode 7, a Hall sensor 8, two flame-retardant wire slots 9, two shunt switches 11, PLC controller 12, three copper plates 13, four installation beams 14, upper cover plate 15, cabinet body 16, three indicator lights 17, second panel 18, nameplate 19, third panel 20, operation panel 21, first panel 22, three connectors 23, three conduits 24 and four shunt fuse banks 10;

[0028] The upper part of the upper cover 15 is provided with a sump 151, the lower part of the lower cover is provided with an embedding groove 153, and the side wall of the upper cover 15 is provided with three water outlets 154, and the three outlets 154 are all communicated with the sump 151;

[0029] The upper panel 152 of the upper cover 15 is in the shape of an upward convex platform, and the water collected in the sump 151 can be collected along the ...

Embodiment 2

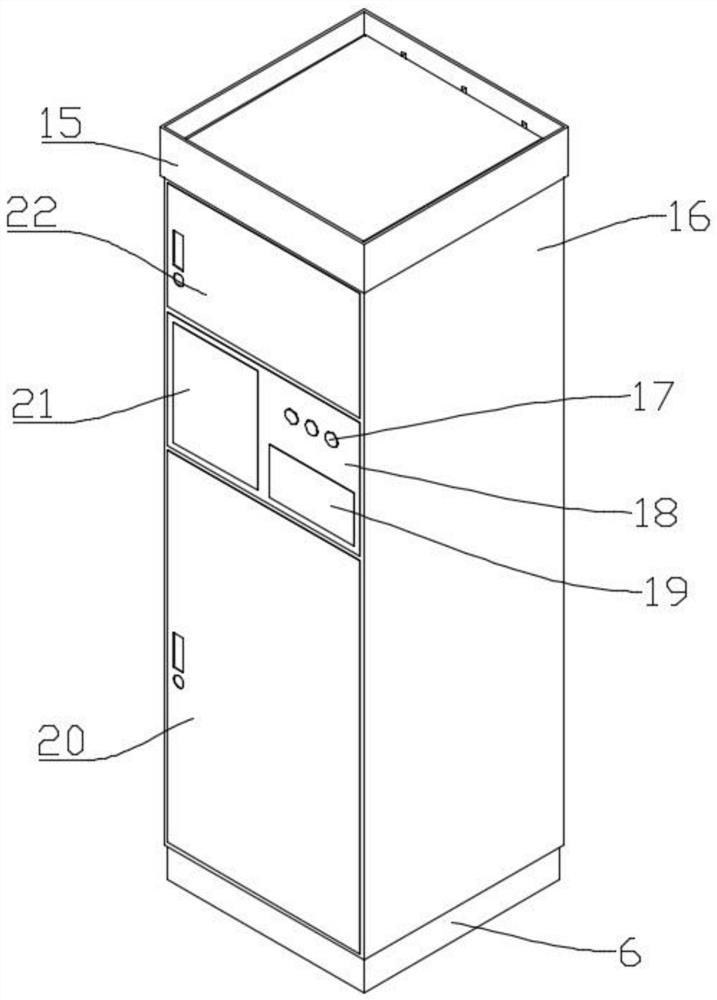

[0040] like Figure 7-12 As shown, a corrosion-resistant shell of a high and low voltage switchgear, a power converter 2, a main switch 4, a base 6, an electrode 7, a Hall sensor 8, two flame-retardant wire slots 9, two shunt switches 11, PLC controller 12, three copper plates 13, four installation beams 14, upper cover plate 15, cabinet body 16, three indicator lights 17, second panel 18, nameplate 19, third panel 20, operation panel 21, first panel 22, three connectors 23, three conduits 24 and four branch circuit breaker groups 25;

[0041] The upper part of the upper cover 15 is provided with a sump 151, the lower part of the lower cover is provided with an embedding groove 153, and the side wall of the upper cover 15 is provided with three water outlets 154, and the three outlets 154 are all communicated with the sump 151;

[0042] The upper panel 152 of the upper cover 15 is in the shape of a slope, and the water collected in the sump 151 can be collected along the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com