Intelligent manufacturing integrated threading machine for a building

An intelligent manufacturing and threading machine technology, applied in manufacturing tools, thread trimmers, metal processing equipment, etc., can solve the problems affecting the continuous installation speed of pipe fittings, the reduction of threading efficiency, and the shaking of pipe fittings, so as to reduce labor consumption and reduce The effect of hidden safety hazards and convenient collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

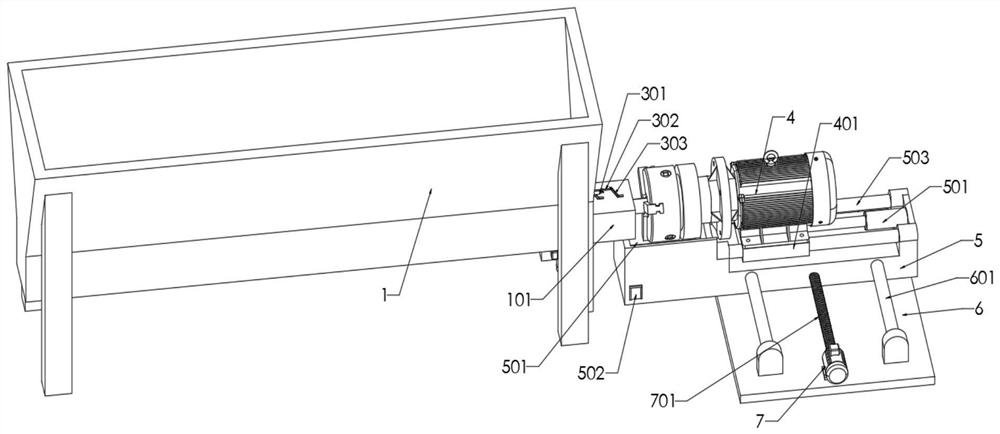

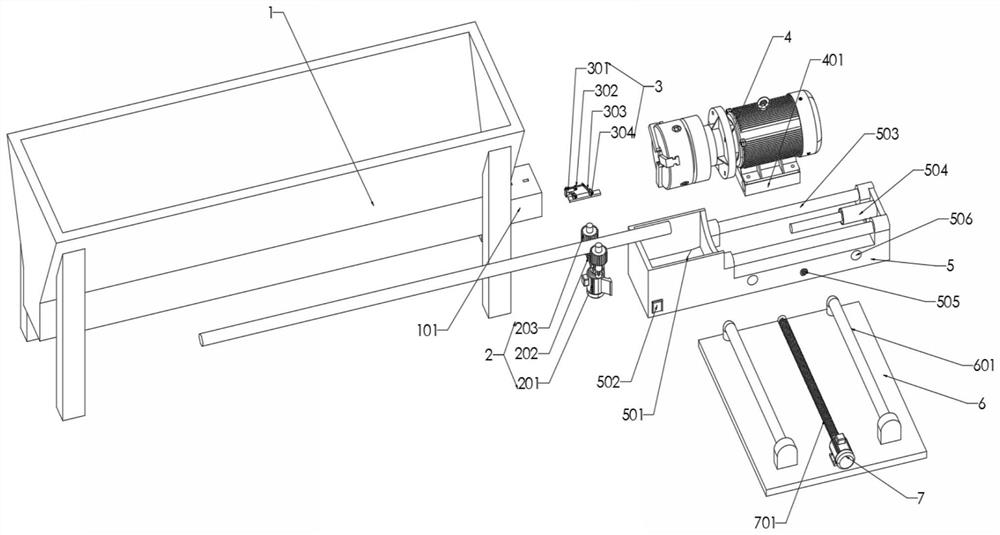

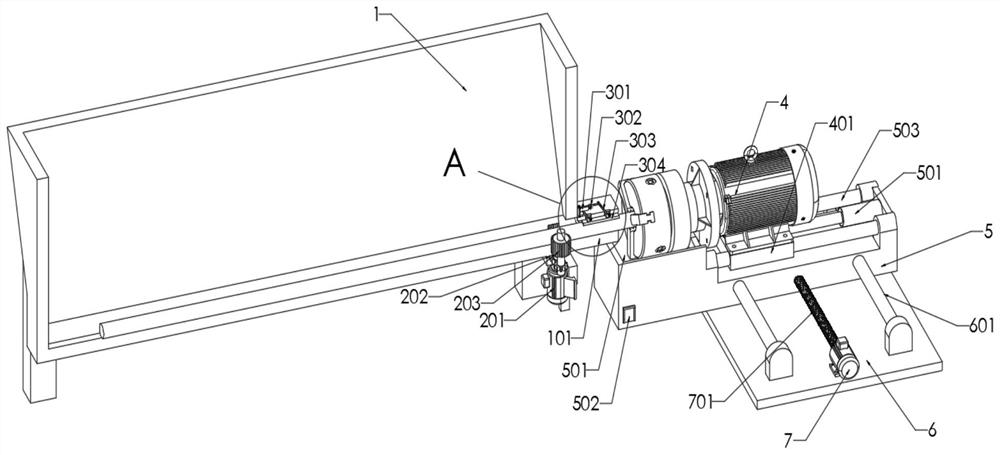

[0044] as attached figure 1 to attach Figure 10 Shown:

[0045] The present invention provides an intelligently manufactured integrated threading machine for construction, including a pipe fitting bucket 1;

[0046] The pipe fitting bucket 1 is in the shape of a tapered funnel, the bottom of the pipe fitting bucket 1 is rectangular, and the bottom of the outer wall on the right side of the pipe fitting bucket 1 is provided with a pipe fitting outlet 101. , the top of the pipe fitting outlet 101 is provided with a pipe fitting fixing assembly 3, the bottom right side of the pipe fitting bucket 1 is connected with a push pipe assembly 2, a fixed base 6 is placed on the ground on the right side of the pipe fitting bucket 1, and a fixed base 6 is installed on the top end surface of the fixed base 6 The screw motor 7, the top of the fixed base 6 is horizontally slidably connected to the sliding platform 5, and the top of the sliding platform 5 is slidably connected to the thread...

Embodiment 2

[0059] The present invention provides an intelligently manufactured integrated threading machine for construction. The difference between the second embodiment and the first embodiment is that the push-pull sliding platform 5 of the screw motor 7 is replaced with the push-pull sliding platform 5 of the electric cylinder, and the push-pull sliding platform 5 of the electric cylinder The sliding platform 5 can make the sliding platform 5 reciprocate more quickly, reduce the waiting time for pipe fitting processing, increase the threading efficiency of the workpiece, and facilitate adaptation to a faster construction environment

Embodiment 3

[0061] The present invention provides an intelligently manufactured integrated threading machine for construction. The difference between Embodiment 3 and Embodiment 1 is that the metal residue box 501 at the left end of the sliding platform 5 is replaced with a cloth bag, which can be used more conveniently. Iron filings are collected and stored to reduce operational complexity.

[0062] The specific usage and function of this embodiment:

[0063] When the present invention is in use, first place pipe fittings or steel bars of equal length into the pipe fitting bucket 1, and then the pusher motor 201 drives the transition gear 202 to rotate through the top gear of the drive shaft, and the transition gear 202 cooperates with the pusher motor 201 to simultaneously drive two pushers. The pipe gear 203 rotates in the opposite direction, so that the pipe is pushed from the bottom of the pipe bucket 1 to the pipe outlet 101 through the push pipe gear 203. When the pipe enters the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com