Type-c shell manufacturing device and production process

A technology for manufacturing devices and shells, which is applied in the direction of manufacturing tools, other manufacturing equipment/tools, forming tools, etc., can solve the problems of easy cracking of shielding shells, achieve simple production processes and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Attached to the following Figure 1-8 This application will be described in further detail.

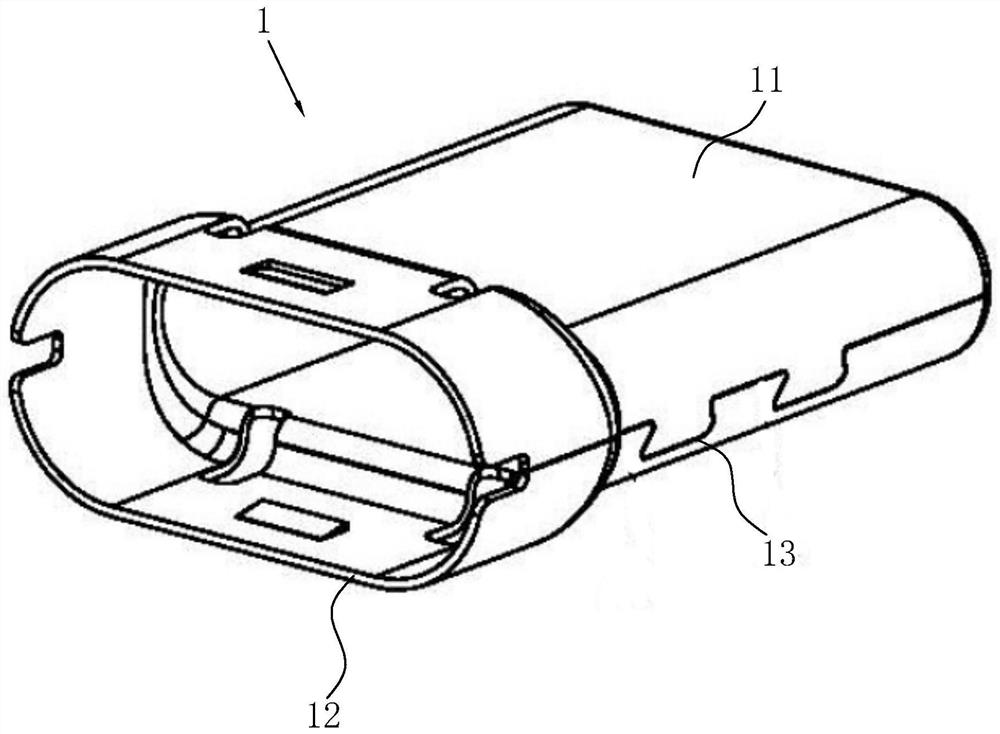

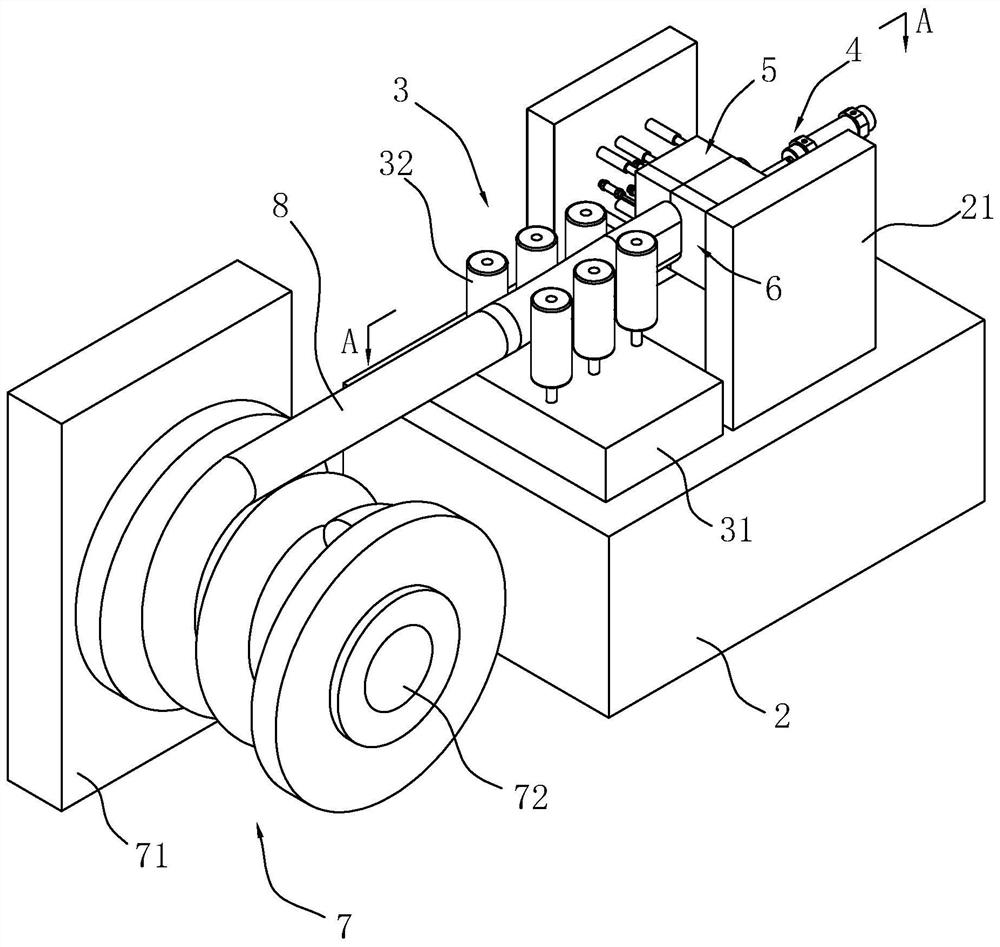

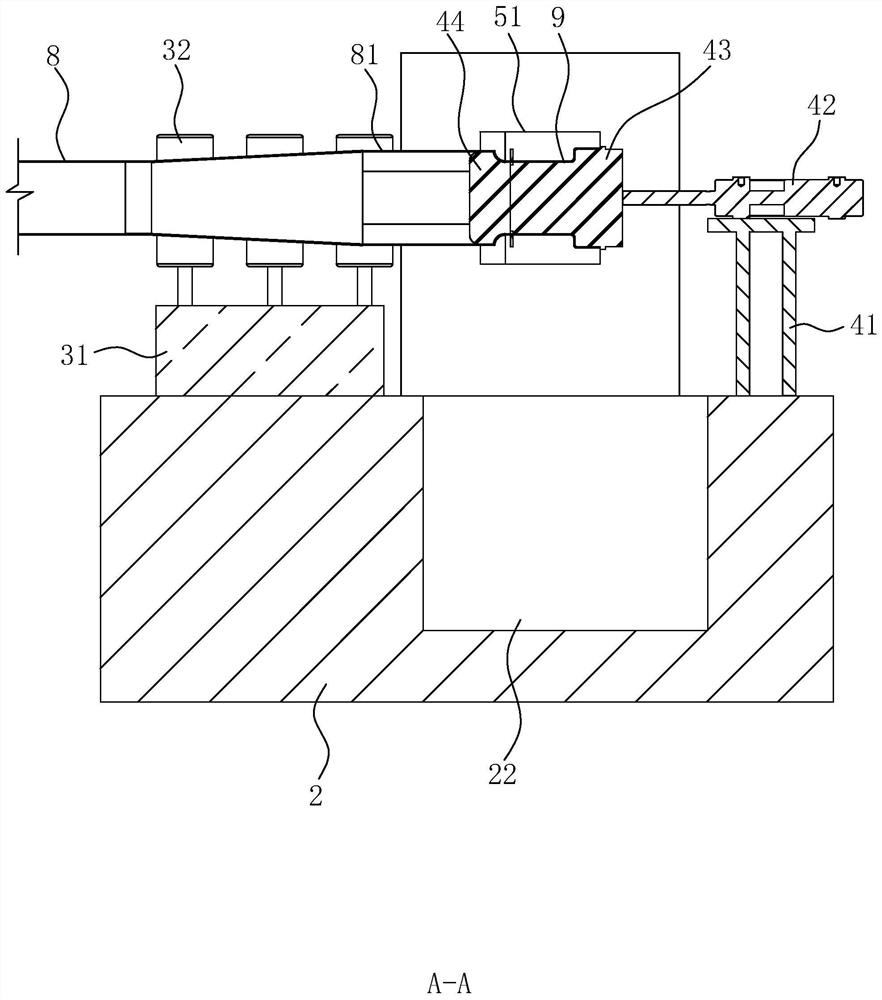

[0042] The embodiment of the present application discloses a Type-C shell manufacturing apparatus. refer to figure 1 and figure 2 , the Type-C shell manufacturing device includes a frame 2 and a pressing mechanism 3, a core mold mechanism 4, a pressing mechanism 5 and a clamping mechanism 6 installed on the frame 2. The frame 2 is located at one end of the pressing mechanism 3. There is a feeding mechanism 7. The raw material pipe 8 is placed on the feeding mechanism 7, and the end of the raw material pipe 8 is pulled through the pressing mechanism 3 and then changed from a circle to an oval blank pipe 81. The seamless casing 9 is formed under the joint action of the clamping mechanism 6 .

[0043] refer to figure 1 , the feeding mechanism 7 includes a bracket 71 and a feeding roller 72, the feeding roller 72 is cylindrical, one end of the feeding roller 72 is supported ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com