Rare earth metal alloy plate surface layer polishing device

A technology of alloy plate and polishing device, which is applied to surface polishing machine tools, grinding drive devices, metal processing equipment, etc., can solve the problems of uneven polishing of alloy plates, no fixing effect, increased labor, etc., and improve the quality of polishing , The effect of saving the work of pressing the grinding wheel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

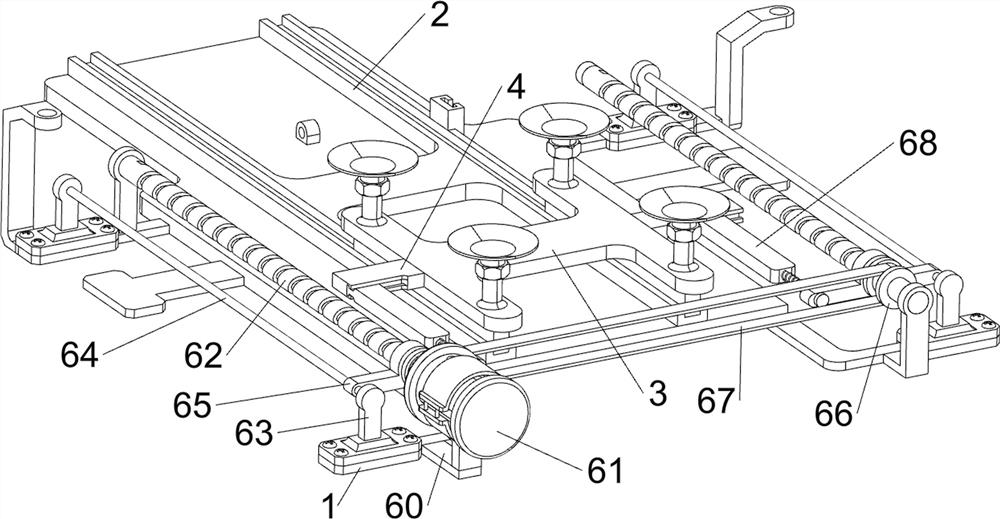

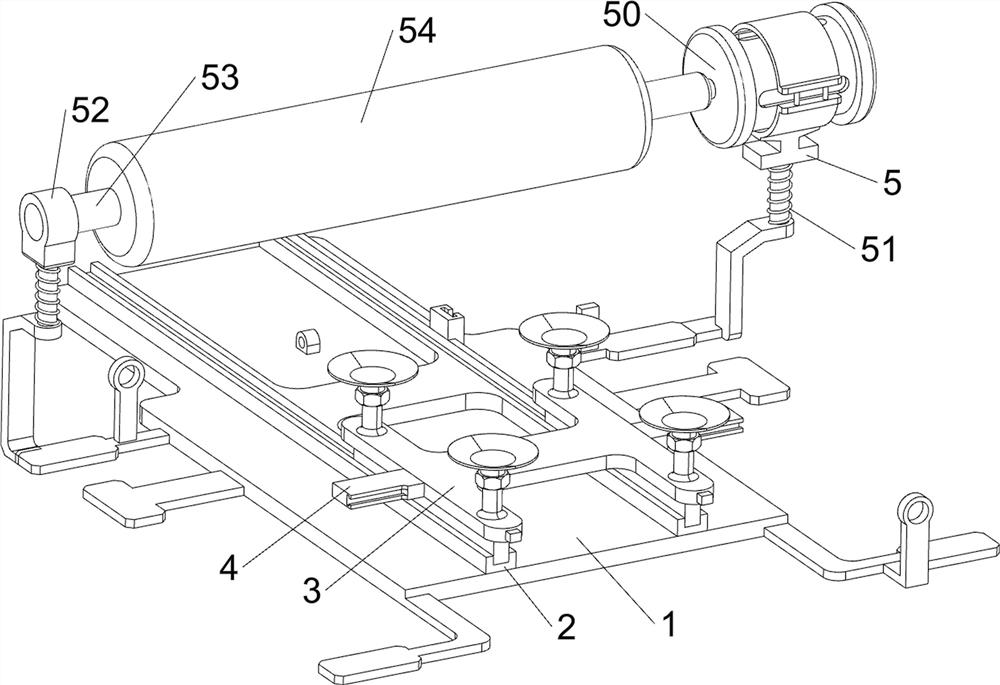

[0096] A rare earth metal alloy plate surface polishing device, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 As shown, it includes a bottom plate 1, a guide plate 2, a slide plate 3, a tray 30, a guide block 4, a first motor chassis 5, a servo motor 50, a first return spring 51, a support block 52, a first rotating shaft 53, Grinding wheel 54, propulsion mechanism 6 and clamping mechanism 7, bottom plate 1 top sliding type is connected with guide plate 2, is provided with slide plate 3 slidingly in guide plate 2, and slide plate 3 top front and rear sides are all provided with two pallets 30 , the left and right sides of the sliding plate 3 are provided with guide blocks 4, the top right rear side of the base plate 1 is slidingly provided with a first motor chassis 5, and a first return force spring 51 is connected between the first motor chassis 5 and the top of the base plate 1 , the t...

Embodiment 2

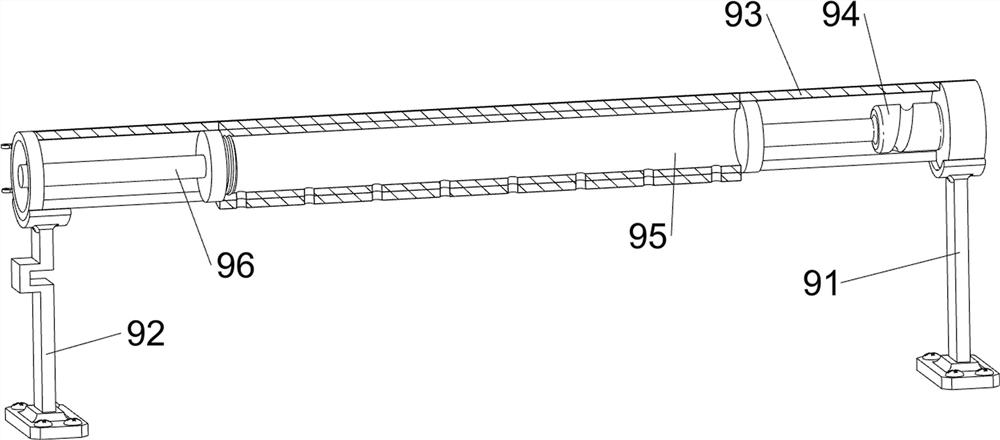

[0103] On the basis of Example 1, such as figure 1 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 , Figure 17 and Figure 18 As shown, a shaking mechanism 8 is also included, and the shaking mechanism 8 includes a gearbox 80, a one-way missing gear 81, a rack frame 82, a block 83, a second limit rod 84 and a fifth return force spring 85, and the top of the bottom plate 1 The right rear side is equipped with a gearbox 80, and the gearbox 80 is in rotation with the right screw mandrel 62. The output shaft of the gearbox 80 is provided with a one-way missing gear 81, and the right side of the guide plate 2 is provided with a block 83, and the block 83 The right side is provided with rack frame 82, and rack frame 82 is meshed with one-way lacking gear 81, and the right side behind guide plate 2 is provided with two second stop rods 84, and the second stop rods 84 are arranged front and back, two A second limiting r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com