Production process and application of transparent 3D glass fiber board with textures

A production process, 3D technology, applied in the production process and application fields of transparent 3D glass fiber sheets, can solve the problems of undurable pattern texture, abrasion, and inability to see the pattern texture from the outside, so as to ensure flatness, high strength, The effect of ensuring light transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

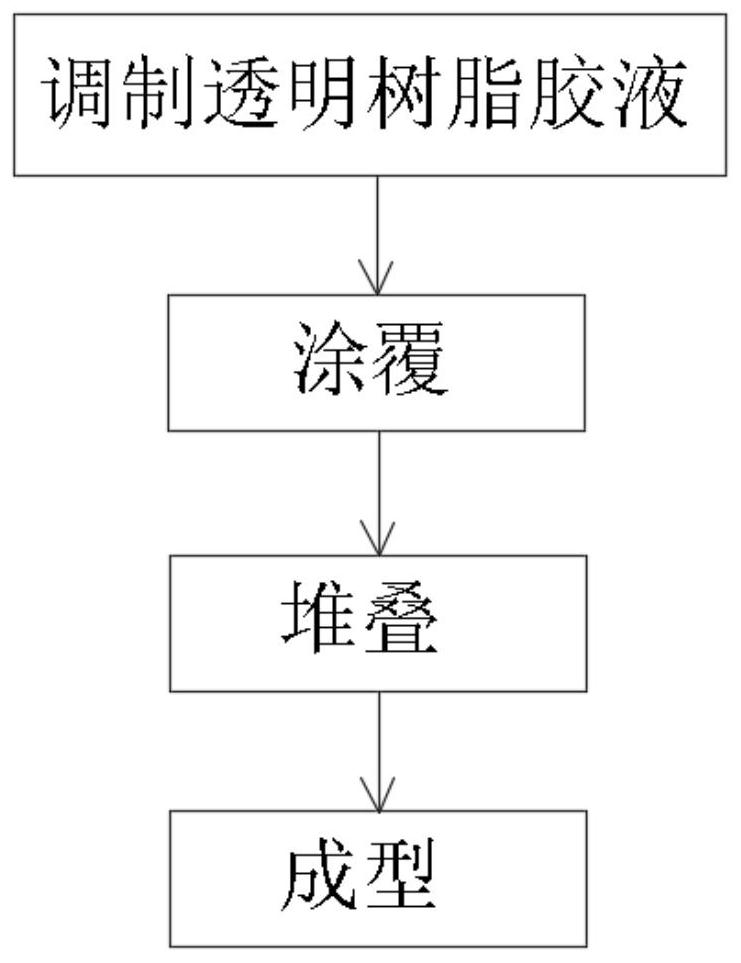

[0033] The invention discloses a production process of a textured transparent glass fiber 3D mobile phone case, such as figure 1 shown, including the following steps

[0034] S1, preparing transparent resin glue; transparent resin glue is prepared by the following method: select 5-30 parts by weight of curing agent and catalyst composition, and add 100-200 parts by weight of resin, 0-50 parts by weight of Organic solvents are mixed and stirred to form.

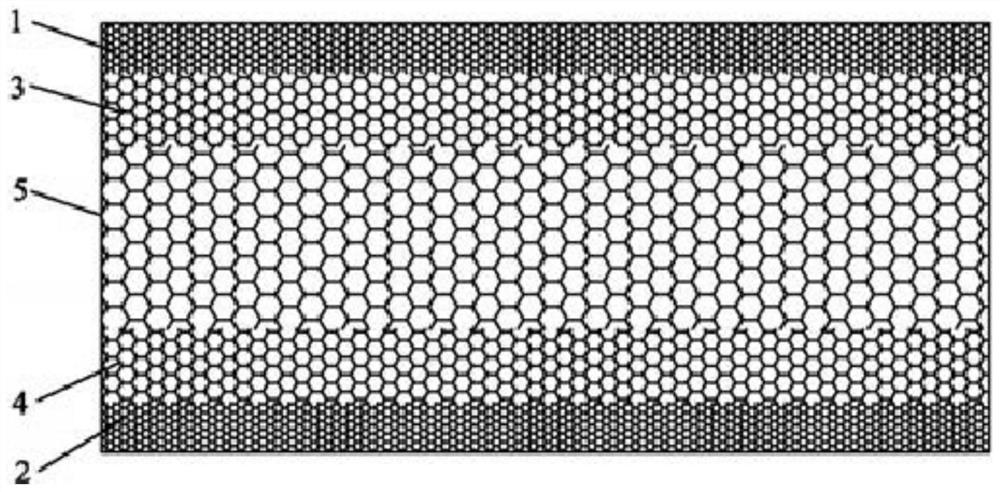

[0035] S2, Coating: After the transparent resin glue is coated or injected on the continuous glass fiber cloth, it is refrigerated at a temperature below 0°C, so that the surface transparent resin glue can be quickly solidified to form a prepreg.

[0036] S3, Stacking: stack multiple layers of prepreg to form a certain thickness, and place a textured film on the surface. The textured film has two layers. The bottom layer is UV glue with texture, and the surface layer is PET as a transfer aid. glue, and the UV glue is next to...

Embodiment 2

[0040] Based on the textured 3D-shaped transparent glass fiber sheet produced in Example 1, the curing agent is a peroxide curing agent, the resin is an unsaturated polyester resin, and the organic solvent is styrene.

[0041] Stir 5 parts of peroxide curing agent and catalyst composition and 25 parts of styrene at 800-1000 rpm for 0.5-1.0 hours to obtain component A 1 , Stir 200 parts of unsaturated polyester resin and 25 parts of styrene at a speed of 800-1000 rpm for 0.5-1.0 hours to obtain component B 1 . Component A 1 and component B 1 Stir and mix in the reaction kettle to form transparent resin glue No. 1.

Embodiment 3

[0043] Different from the curing agent, resin and organic solvent in Example 2, the curing agent in Example 3 is a peroxide curing agent, the resin is polyurethane resin, and the organic solvent is acetone. Mix and stir 30 parts of peroxide curing agent and catalyst composition with 10 parts of acetone to obtain component A 2 , Mix and stir 100 parts of polyurethane resin and 10 parts of acetone to obtain component B 2 . Component A 2 and component B 2 Stir and mix in the reaction kettle to form transparent resin glue No. 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com