Self-supporting, self-inflating and self-adapting tire device and method

An adaptive and self-supporting technology, which is applied in tire measurement, motorcycle tires, tire parts, etc., can solve the problems of high rolling resistance, high sliding resistance, and insufficient outward support of the bead to achieve improved shock absorption performance, increased inflation efficiency and pressure effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

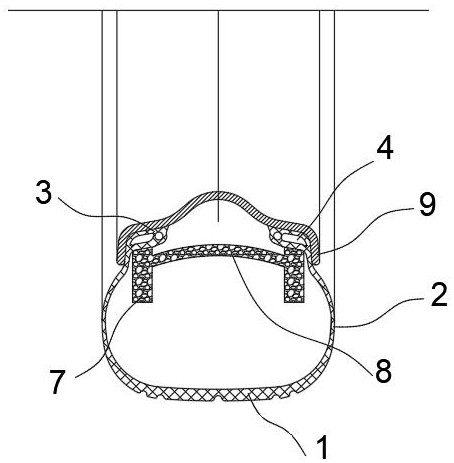

[0037] Embodiment one: if figure 1 As shown in , the present invention adopts a tubeless tire structure, and the bead 2 adopts an ultra-thin design, and the thickness is controlled to be less than about 2mm.

[0038] In the present invention, the supporting ring 7 is arranged in the tire cavity, which can provide supporting force in the radial direction and the axial direction, so that the ultra-thin tire does not rely on the outward supporting force of the bead 2, but relies on the lateral support 8 of the supporting ring 7 Provides axial support, compressible in this direction to ensure tire fit. In the initial installation state of the tire, under the action of the lateral support 8 of the support ring 7, the tire bead 3 on both sides of the tire 1 is approached to the inner wall of the rim 9, and pressed tightly so that the bead 3 and the rim 9 Form-fitting seal allows for initial inflation.

Embodiment 2

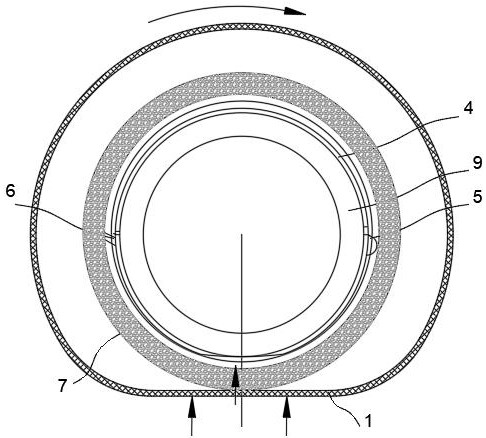

[0039] Embodiment two: if figure 2 As shown in , the figure shows the multi-turn structure of the peristaltic pump, which is arranged in two circles in a helical shape.

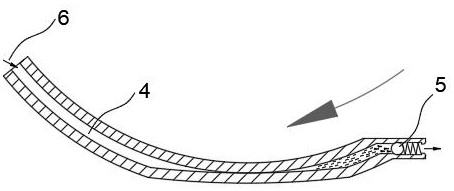

[0040] The peristaltic pump 4 for inflation is set at the bead 3, the pump tube is arranged around the bead 3 of the tire, and the pump pipe mouth is used as the air inlet 6; cavity. When the tire is under-inflated, the support ring rolls the upward pressure from the ground to the peristaltic pump, so that the peristaltic pump pumps air into the tire cavity round by round. The inflation pressure is automatically adjusted according to the weight of the rider, forming an adaptive .

[0041]As the tire rolls and rotates forward, the flattened peristaltic pump 4 pipe sections sequentially pressurize the one-way inflation valve 5, and the peristaltic pump 4 completes a cycle of inflation every time the tire is pressed and rolled one circle.

[0042] The peristaltic pump 4 is made of elastic and flexible materi...

Embodiment 3

[0053] Embodiment three: as Figure 6 , the 4 tubes of the peristaltic pump are prefabricated into a kind of elastic tube, just like the bamboo joints, a section of a sealed long tube, and an oblique opening 11 is opened at 10 joints of the air tube of each bamboo joint, which is a micro-opening, and is deflected from the outside of the tube with a blade. Insert it obliquely, and cut air holes at the eccentric edge of the bamboo joint to form a tongue valve for one-way ventilation. The plurality of bamboo peristaltic pumps 4 are connected in series so that the air can only be pumped to flow in the tire cavity, and the one-way inflation valve 5 can also be omitted. The air in the 4 tubes of the slub peristaltic pump can only be sucked in by the air inlet 6, and then rolled and pressed into the tire cavity by the wheel load pressure to realize the self-inflating function.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com