Bismuth titanate-based bismuth layered structure lead-free piezoelectric ceramic with negative electrocaloric effect and preparation method thereof

A bismuth titanate-based bismuth, lead-free piezoelectric technology, applied in the field of electronic functional materials and devices, can solve problems such as application limitations of lead-containing films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

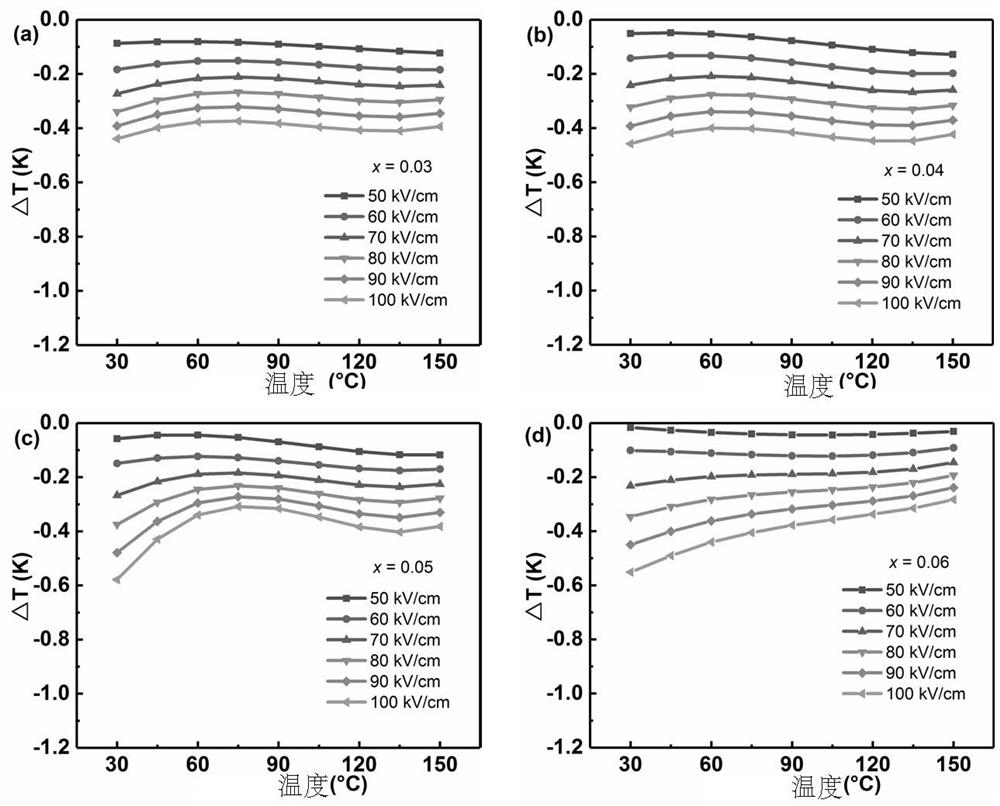

[0040] Preparation of bismuth titanate-based bismuth layered structure lead-free piezoelectric ceramic Bi with negative charge card effect by solid-state reaction method 4- x Ce x Ti 2.98 (WNb) 0.01 o 12 . Wherein, x=0.03. Weigh Bi according to the stoichiometric ratio 2 o 3 、TiO 2 、WO 3 , Nb 2 o 5 , CeO 2 powder, and use it as a raw material. The raw materials are mixed by wet ball milling method, the mass ratio of raw materials: balls: alcohol = 1:1.5:0.75, and ball milled for 4 hours to mix all components uniformly to obtain a mixture. Dry the mixture and pass it through a 40-mesh sieve. After briquetting at 5MPa, raise the temperature to 850°C at a rate not higher than 2°C / min and keep it warm for 2 hours to obtain a calcined block. Grind and crush the calcined block, pass through a 40-mesh sieve, continue to mix according to the wet ball milling method, the mass ratio of mixture: balls: alcohol = 1:2:0.65, ball mill for 4 hours and then dry to obtain ceramic...

Embodiment 2

[0042] It is basically the same as Embodiment 1, the only difference is that x=0.04.

Embodiment 3

[0044] It is basically the same as Embodiment 1, the only difference is that x=0.05.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com