Prefabricated prestressed high-performance concrete composite beam based on dry connection and construction method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

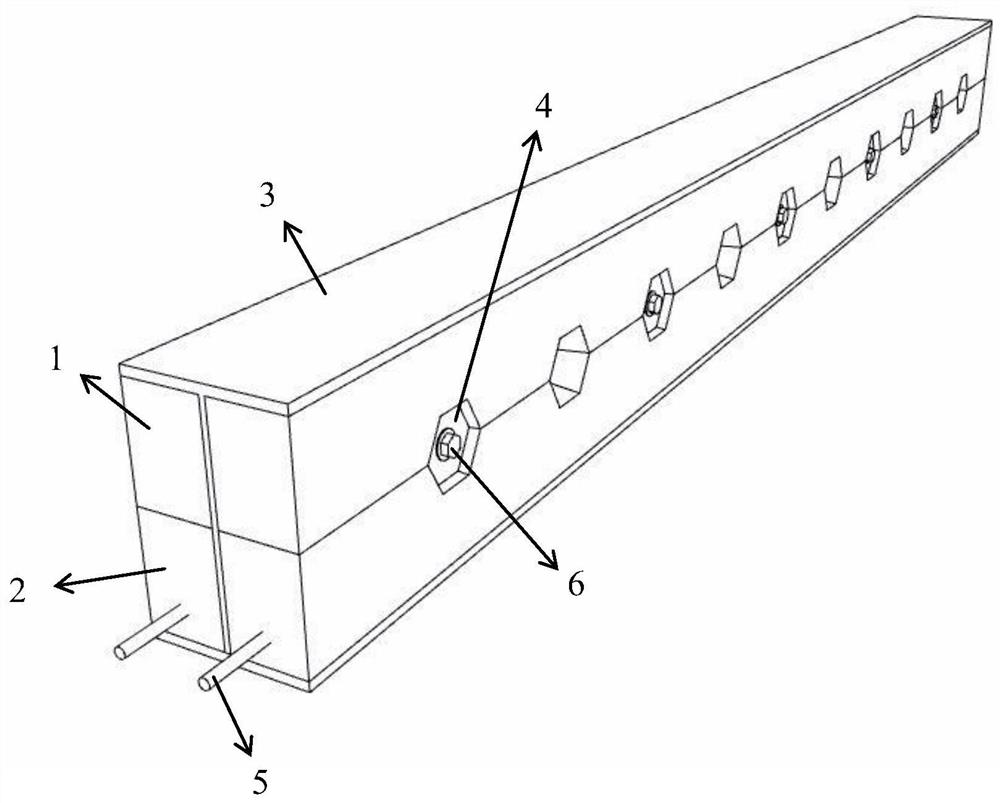

[0043] Such as figure 1 As shown, the present invention is a prefabricated prestressed high performance concrete composite beam based on dry connection, comprising:

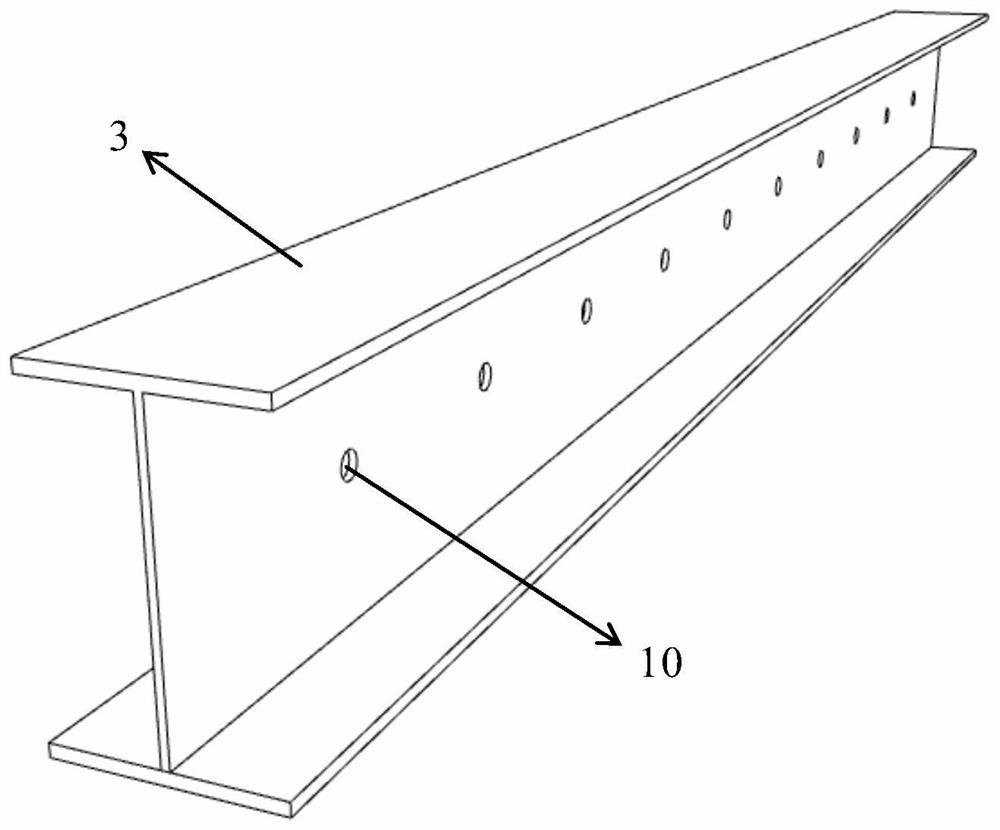

[0044] The I-beam 3 has several round holes 10 pierced on its web along the length direction, such as figure 2 As shown, from the upper flange to the lower flange, the round holes 10 can be arranged in one row, or in multiple rows.

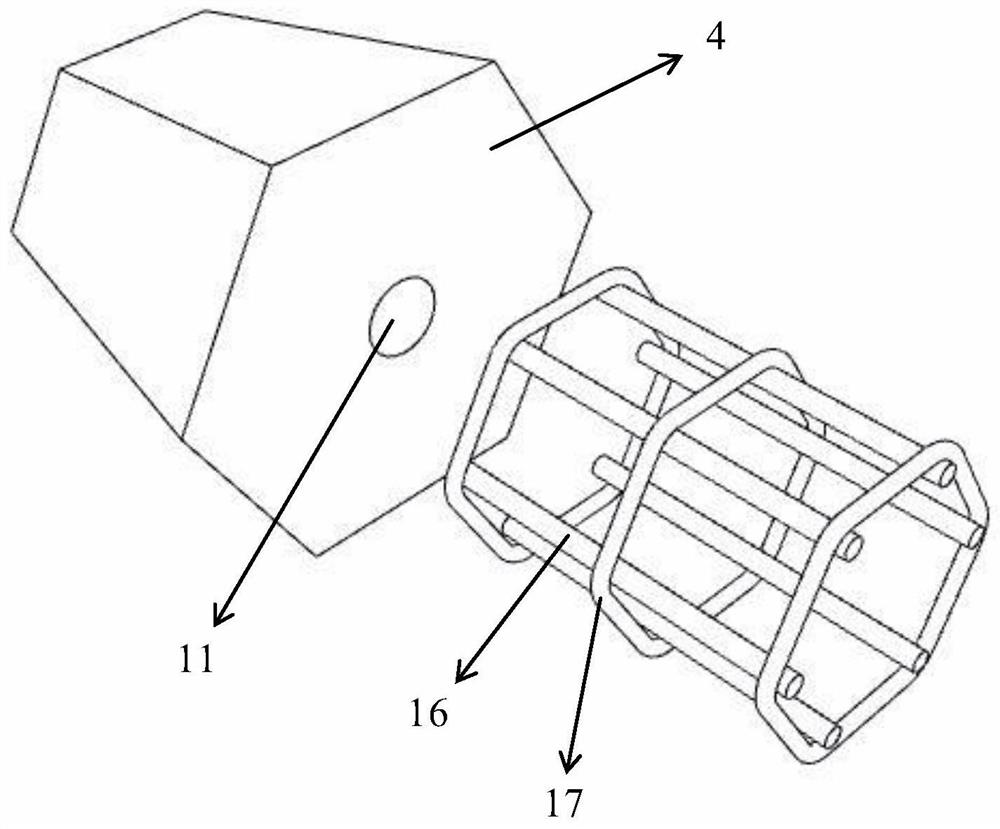

[0045] The split concrete strip is arranged on both sides of the web of the I-beam 3, and is located between the upper and lower flanges, and a through hole is opened on it, and the through hole is coaxial with the round hole 10. Wherein, the via hole on at least one side is a gradually widening hole, and the gradually widening hole means that the diameter of the hole increases linearly along the direction from the web to the outside.

[0046] Prec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com