LED lamp box with automatic heat dissipation function and convenient light source replacement function

A technology for replacing LED light boxes and light sources, which is applied in the direction of light sources, electric light sources, and light source fixation. It can solve problems such as accelerated LED light decay, reduced lifespan, and impact on lighting effects, and achieves the effects of easy replacement and reduced risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

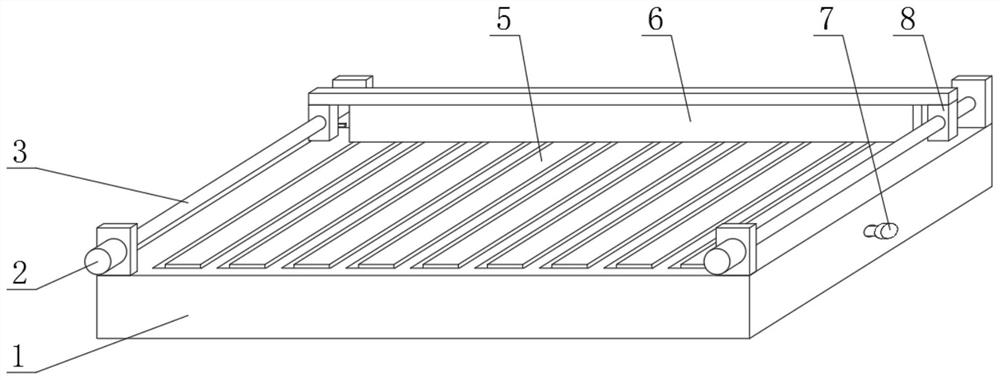

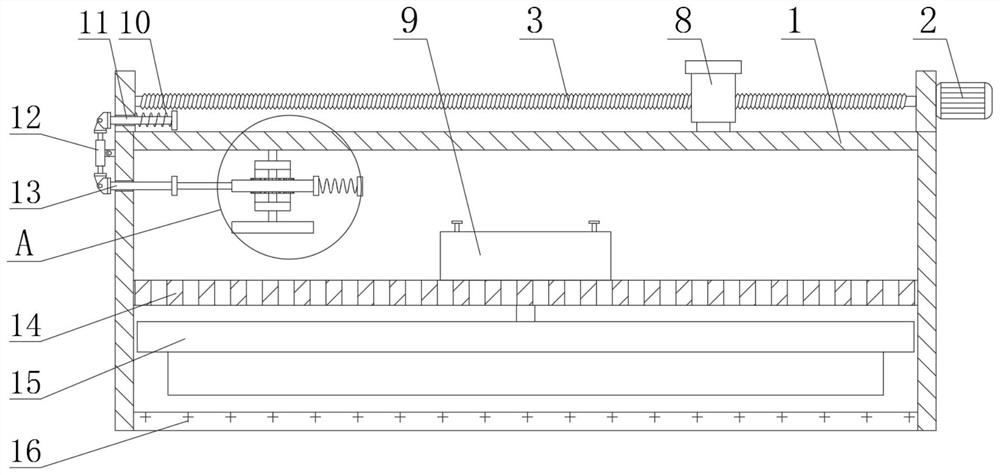

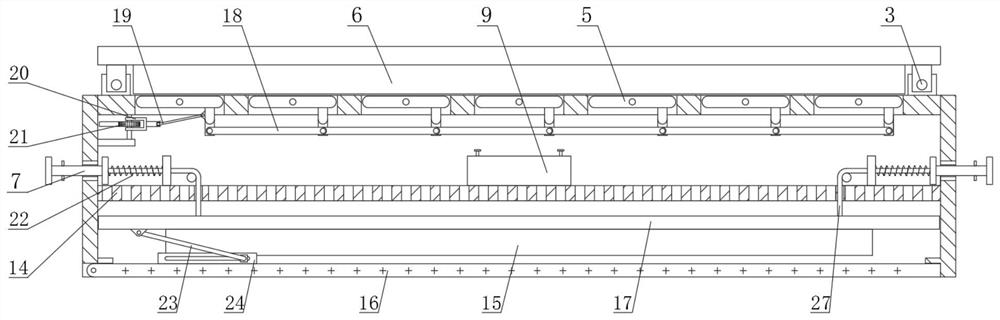

[0024] See Figure 1-7 The present invention provides a technical solution:

[0025] With an automatic cooling and easy replacement of the LED light box, comprising a box body 1, the upper end of the main body 1 of the box are fixedly connected with the left and right sides of the motor 2, and the motor output shaft 2 fixedly connected to the lead screw 3, the screw 3 outer screw thread is connected to the block 8, and the upper end of the screw block 8 is fixedly connected with the blade 6, an upper box body 1 is rotated as a heat dissipation plate connected equispaced about 5, and the lower side of the radiator plate 5 is rotatably connected to fourth link 18, the leftmost side of the radiator plate 5 is rotatably connected to a rod 19, and the other end of the rod 19 is rotatably connected to a rotary block 20, block 20 is rotated one side gear 21 is fixedly connected, and a gear 21 the upper and lower ends are rotatably connected with a box body 1, the outer ring gear 21 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com