Vehicle-mounted center control plane glass cover plate flatness detection device

A technology of flatness detection and glass cover, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of reducing detection accuracy and detection errors, and achieve the effects of ensuring the detection area, convenient operation, and reducing detection errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

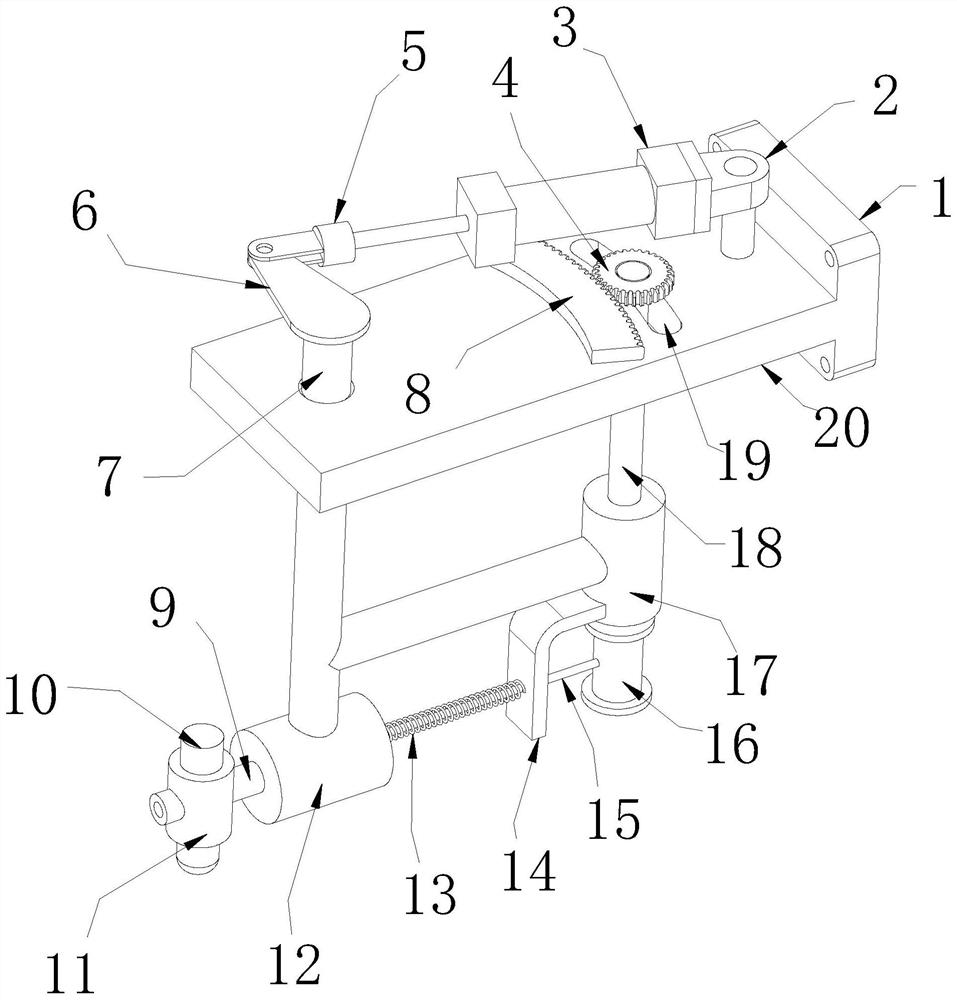

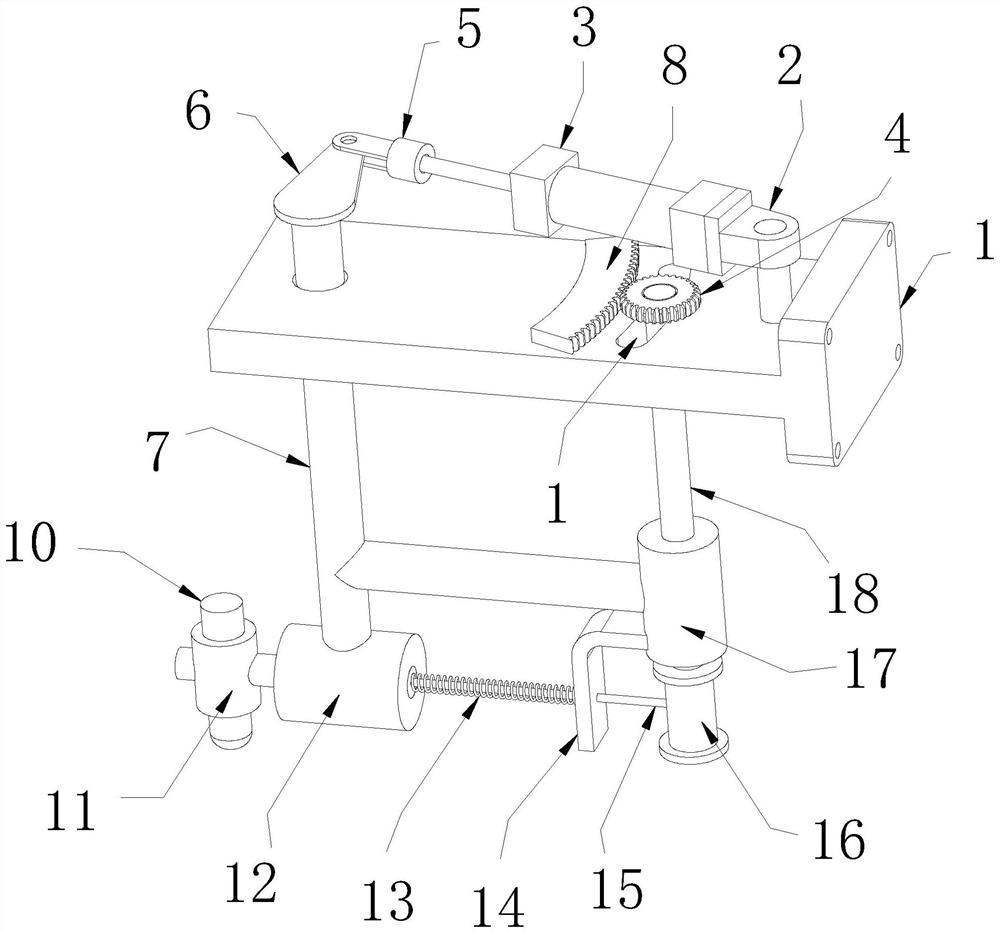

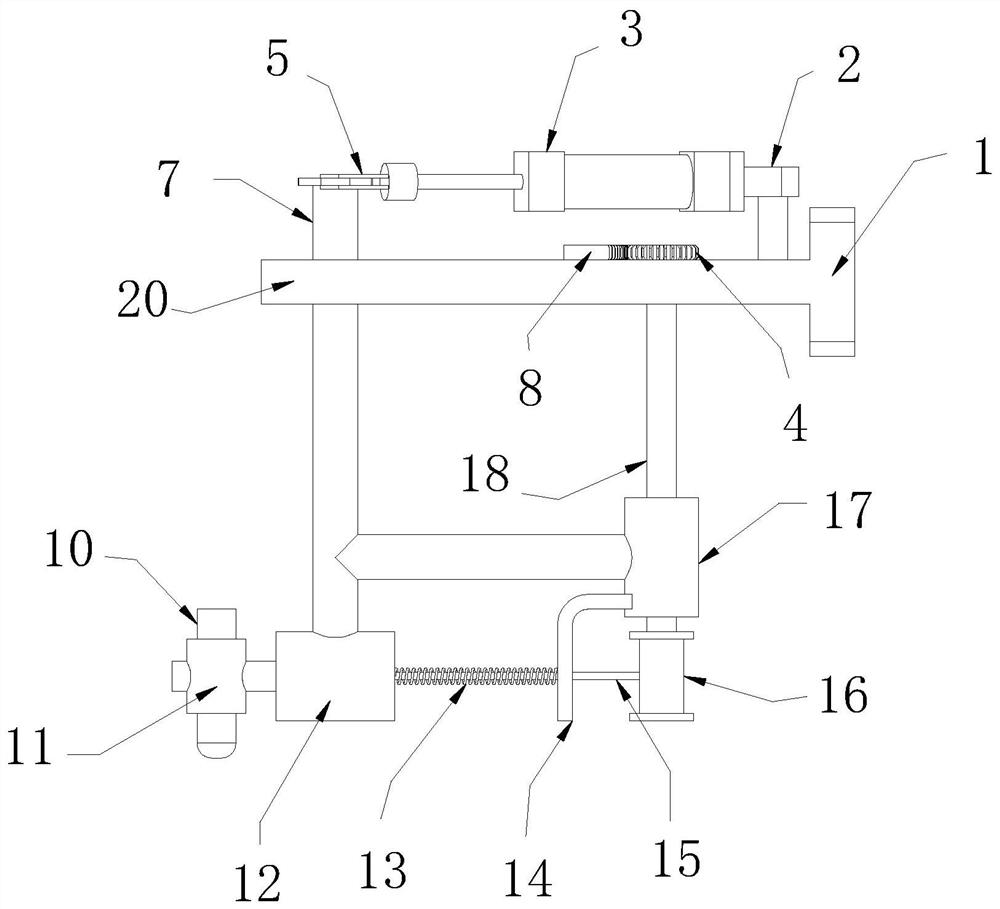

[0022] Such as Figure 1-3 As shown, a vehicle-mounted central control plane glass cover flatness detection device includes a fixed seat 1 connected to an external flatness detection device, a mounting seat 20 is provided on the fixed seat 1, and one end of the mounting seat 20 is away from the fixed seat 1 The vertical rotation is connected with a rotating shaft 7, which is driven by the rotating drive assembly to swing around its own axis. The lower end of the rotating shaft 7 is provided with a mounting sleeve 12, and the mounting sleeve 12 is provided with a sliding rod 9 that can slide freely horizontally. 9. A laser head 10 is detachably installed at one end. The structure and working principle of the laser head 10 have been disclosed in the prior art, and will not be repeated here. The rotating shaft 7 is connected with a rotating sleeve 17 through a cross bar. 17 is coaxially connected with a driven shaft 18, the lower end of the driven shaft 18 is coaxially fixed with...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap