Textile color fastness inspection device for intelligent manufacturing

A technology of intelligent manufacturing and inspection devices, which is applied in the field of textile inspection, can solve problems such as inconsistency, visual error color standards, etc., and achieve the effects of promoting fading, ensuring accuracy, and facilitating color fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

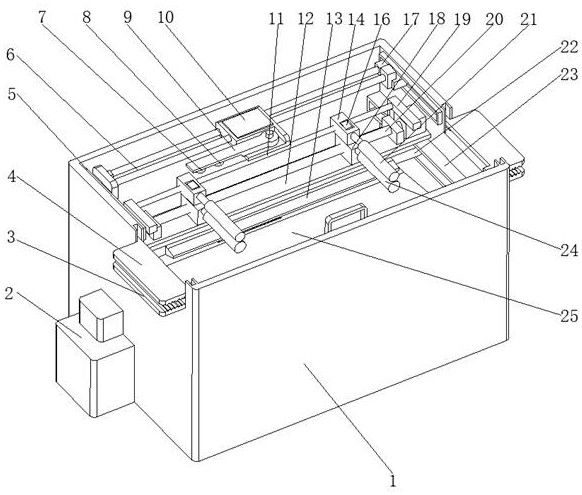

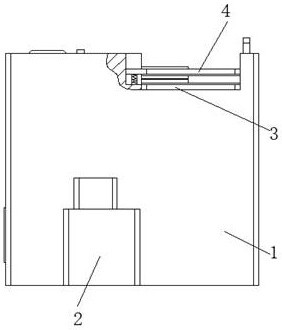

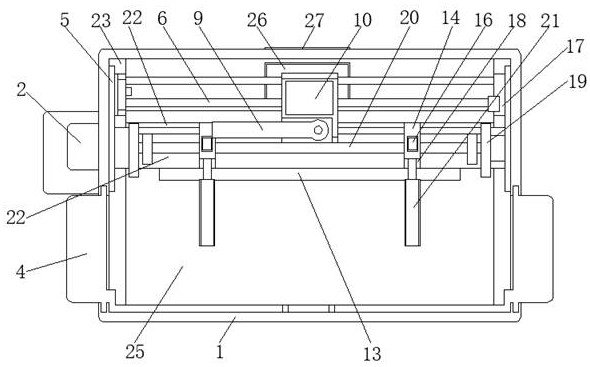

[0032] Such as Figure 1-6 As shown, the embodiment of the present invention provides a textile color fastness inspection device for intelligent manufacturing, including a housing 1, a lower splint 3 is fixedly connected to the grooves of the left and right side walls of the housing 1, and the grooves of the left and right side walls of the housing 1 slide An upper splint 4 is connected, and the two upper splints 4 are connected by a connecting plate with a handle. The upper splint 4 is located above the lower splint 3, and the opposite sides of the two are provided with anti-skid grooves. The upper splint 4 is located on the side of the shell 1. The lower surface inside the wall is fixedly connected with a spring, and the lower end of the spring is fixedly connected with the bottom of the groove of the side wall of the housing 1, and when pulled up from the handle of the connecting plate with handle, the upper splint 4 can move upward against the tension of the spring , the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com