Parameter checking method, device and system based on model reference

A technology of parameter checking and model reference, applied in the field of parameter checking, it can solve the problems of increasing the risk of power grid accidents, imperfect performance indicators, and failure to consider the response characteristics of the power grid.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] An embodiment of the present invention provides a parameter checking method based on model reference, including:

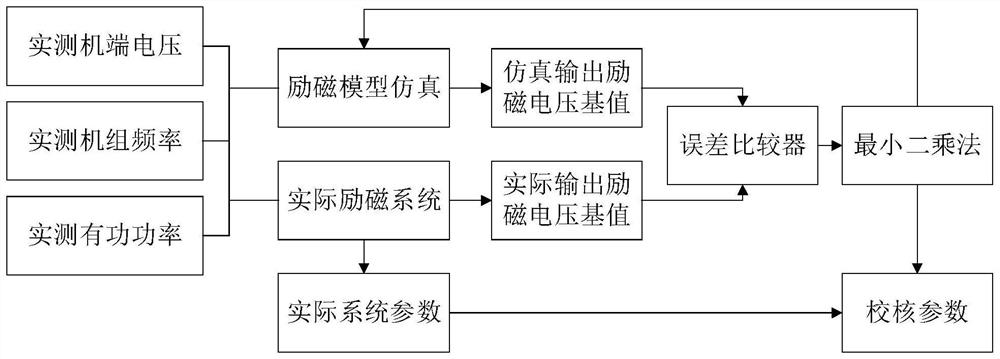

[0041] Obtaining the base value of the simulated output excitation voltage and the base value of the actual output excitation voltage, the base value of the simulated output excitation voltage and the base value of the actual output excitation voltage are obtained by simultaneously sending the input unit data to the excitation simulation model and the actual excitation system, wherein , the excitation simulation model is obtained according to the actual model structure of each unit; as figure 1 As shown, the input unit data includes the measured machine terminal voltage, the measured unit frequency, the measured active power and the given machine terminal voltage;

[0042] Sending the simulated output excitation voltage base value and the actual output excitation voltage base value into an error comparator to obtain an error signal;

[0043] Sending the er...

Embodiment 2

[0060] Based on the same inventive concept as in Embodiment 1, an embodiment of the present invention provides a parameter checking device based on model reference, including:

[0061] The obtaining unit is used to obtain the base value of the simulated output excitation voltage and the base value of the actual output excitation voltage, the base value of the simulated output excitation voltage and the base value of the actual output excitation voltage are obtained by simultaneously sending the input unit data to the excitation simulation model and the actual excitation system, wherein the excitation simulation model is obtained according to the actual model structure of each unit; as figure 1 As shown, the input unit data includes the measured machine terminal voltage, the measured unit frequency, the measured active power and the given machine terminal voltage;

[0062] An error signal calculation unit, configured to send the simulated output excitation voltage base value an...

Embodiment 3

[0072] An embodiment of the present invention provides a model reference-based parameter calibration system, including a storage medium and a processor;

[0073] The storage medium is used to store instructions;

[0074] The processor is configured to operate according to the instructions to execute the method according to any one of Embodiment 1.

[0075] Those skilled in the art should understand that the embodiments of the present application may be provided as methods, systems, or computer program products. Accordingly, the present application may take the form of an entirely hardware embodiment, an entirely software embodiment, or an embodiment combining software and hardware aspects. Furthermore, the present application may take the form of a computer program product embodied on one or more computer-usable storage media (including but not limited to disk storage, CD-ROM, optical storage, etc.) having computer-usable program code embodied therein.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com