Zero-tooth-difference-output secondary transmission part structure of automobile seat lifting motor

A technology of car seat and motor 2, applied in electric components, electrical components, electromechanical devices, etc., can solve the problems of low mechanical efficiency, unreliable self-locking, irreparable, etc., and achieve improved mechanical efficiency, high self-locking strength, high-performance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing, the present invention will be further described with regard to specific embodiment:

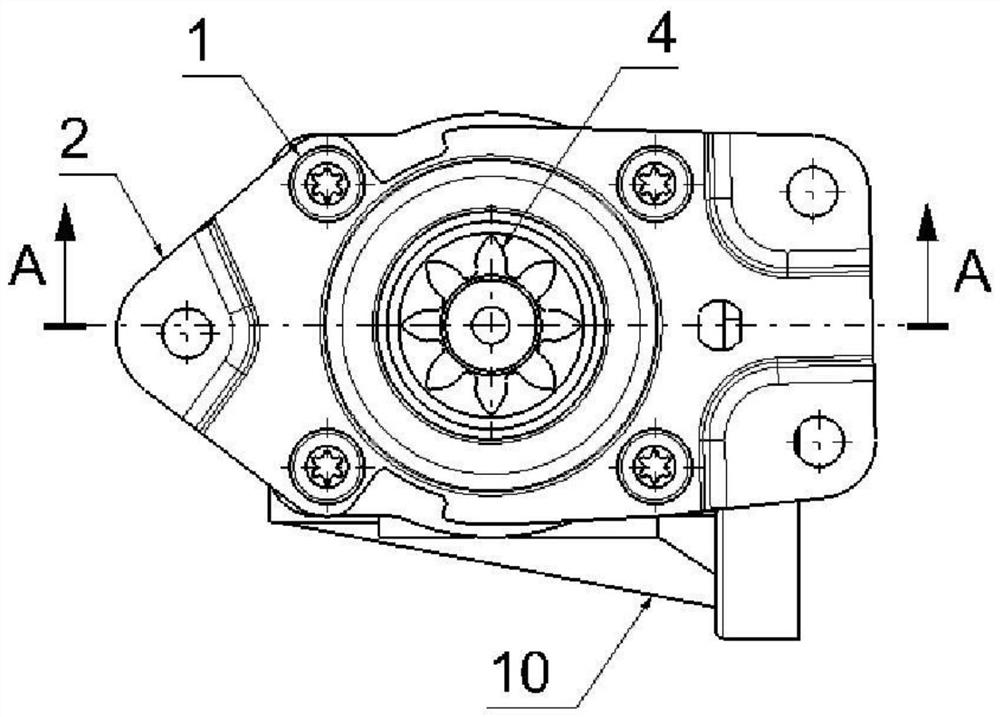

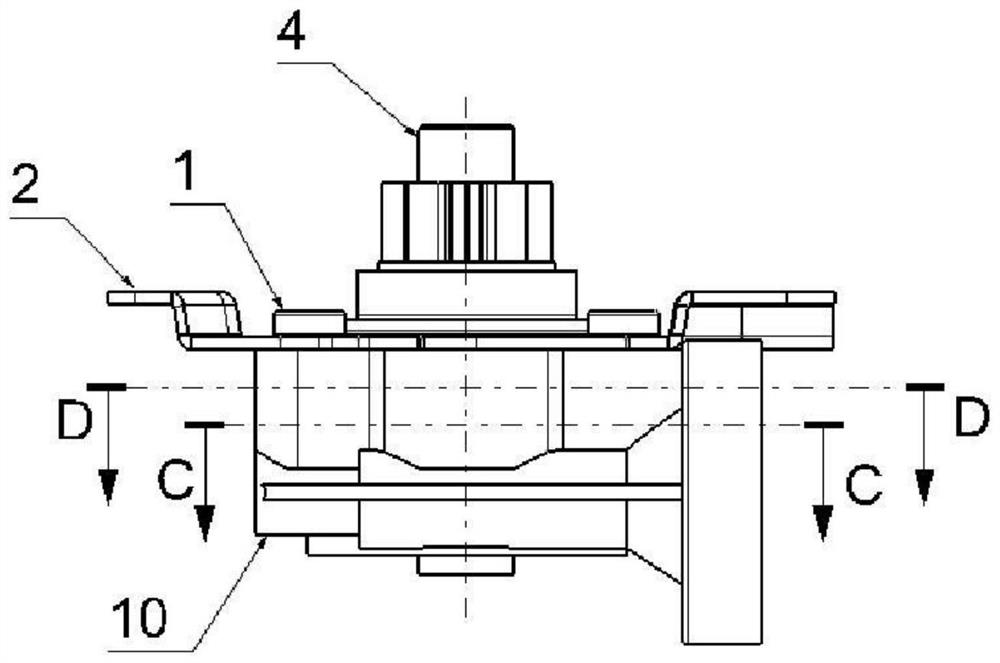

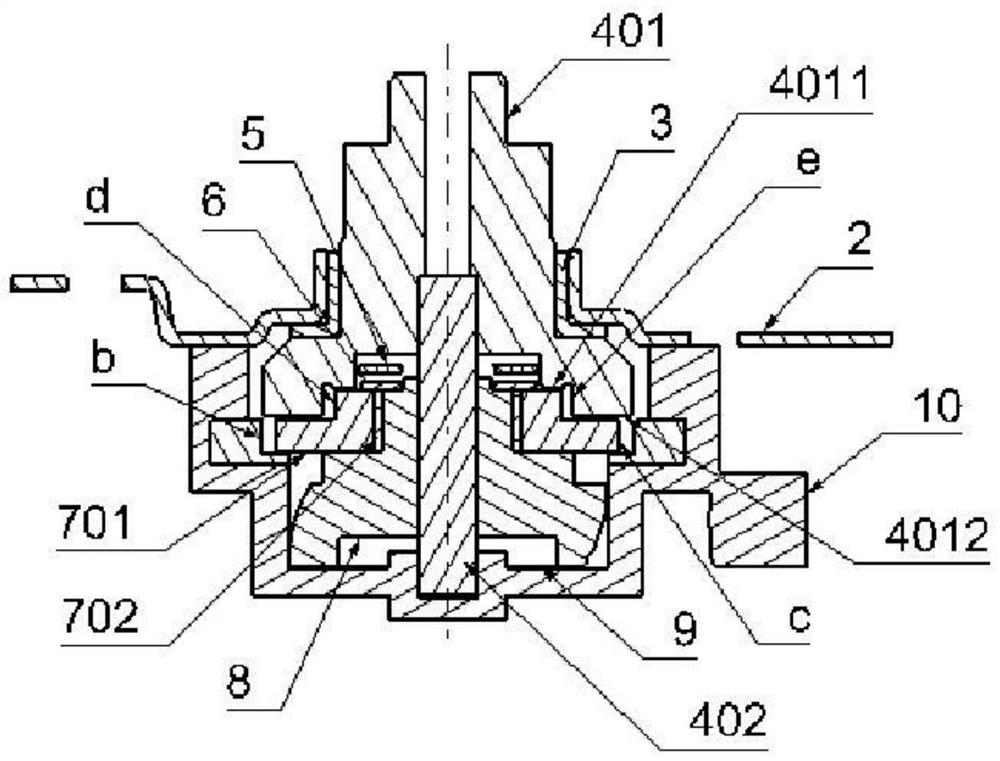

[0034] Such as Figure 1-11 As shown, the structure of the secondary transmission part of the car seat raising motor with zero tooth difference output of the present invention consists of a screw 1, a cover plate 2, a plastic bushing 3, an output gear assembly 4, a wave washer 5, and a compression gasket 6. The planetary gear assembly 7, the helical gear 8, the box bottom gasket 9, and the box body 10 are composed.

[0035] Such as Figure 5 , Figure 6 As shown, the box body 10 made of plastic is provided with a ring gear b with metal inserts and few tooth differences. Such as Figure 7 As shown, there is a metal insert eccentric wheel 801 on the helical gear 8 made of plastic material. Such as Figure 8 As shown, the planetary wheel assembly 7 is composed of a planetary wheel 701 and a Teflon bushing 702 that reduces friction. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com