Oil well cement drag reducer

A technology of oil well cement and drag reducing agent, which is applied in the field of oil well cement drag reducing agent. It can solve the problems that the drag reducing agent cannot effectively suspend cement particles and the slow development of cement stone strength, so as to achieve good drag reducing effect, ensure strength and ensure dispersion effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

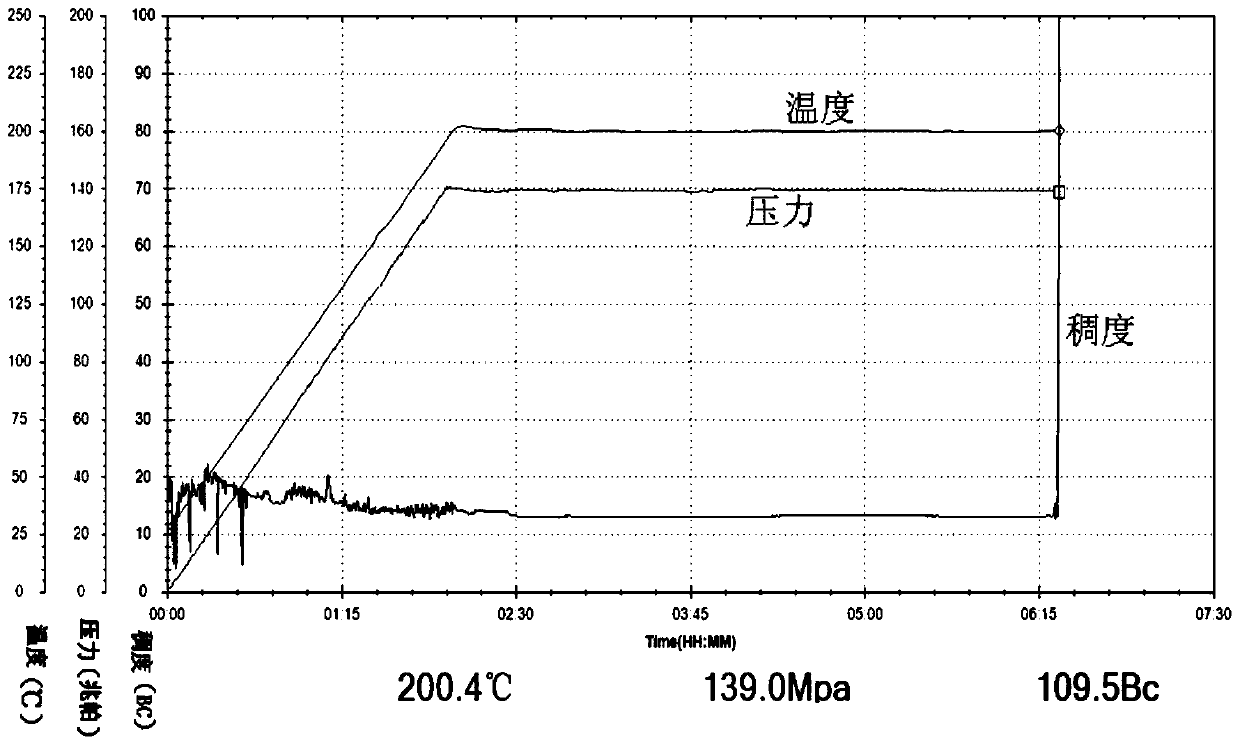

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

[0027] A kind of oil well cement drag reducing agent, composition and weight fraction are as follows:

[0028] The molar ratio of acetone: sodium bisulfite: formaldehyde: Vc is 6:3:1:1.5

[0029] The preparation method of above-mentioned drag reducer is as follows:

[0030] ⑴ According to the required molar ratio, add acetone, sodium bisulfite, and formaldehyde to the water in the reaction kettle in sequence, stir evenly, and prepare an aqueous solution;

[0031] (2) Then use caustic alkali to catalyze, and the amount of caustic alkali (NaOH or KOH) added is 2wt%;

[0032] (3) The reaction temperature is 80°C, and the temperature is kept for 3 hours to obtain the polymer product.

[0033] ⑷ After the product is obtained, add Vc to compoun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com