A kind of butyronitrile latex auxiliary material used for preparing white nitrile gloves and preparation method thereof

A technology of white nitrile and nitrile rubber, which is applied in the field of nitrile gloves, can solve the problems of long purchase cycle, different addition amount, heavy workload, etc., and achieve the improvement of pinhole pass rate, reduction of fine particle size, and production cost Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

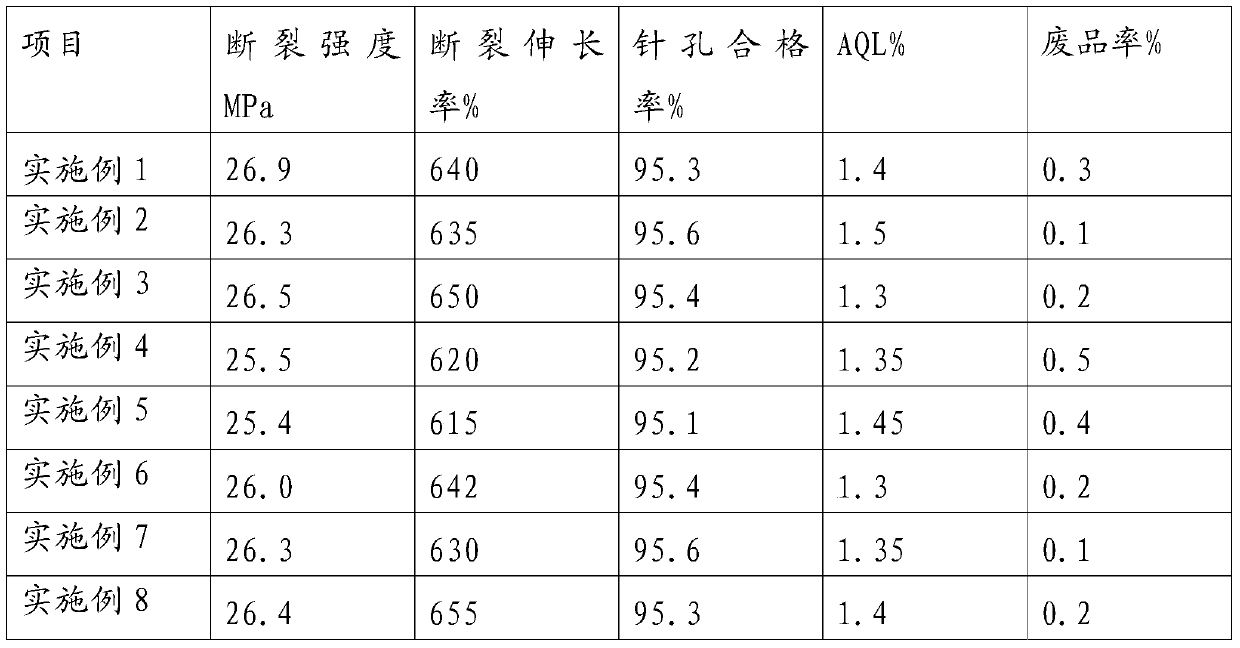

Examples

Embodiment 1

[0027] A kind of nitrile latex auxiliary material that white nitrile gloves are used comprises the raw material component of following parts by weight:

[0028] 20 parts of zinc oxide powder, 22 parts of sulfur powder, 4 parts of accelerator BZ powder, 6 parts of accelerator EZ powder, 5 parts of antioxidant KY-616 powder, 41 parts of titanium dioxide, 2 parts of dispersant NNO powder and 100 parts of Water, the particle size of each raw material component is 3-5 μm.

Embodiment 2

[0030] A kind of nitrile latex auxiliary material that white nitrile gloves are used comprises the raw material component of following parts by weight:

[0031] Zinc oxide powder 21 parts, sulfur powder 23 parts, accelerator BZ powder 5 parts, accelerator EZ powder 7 parts, antioxidant KY-616 powder 5 parts, titanium dioxide 41 parts, dispersant NNO powder 3 parts and 105 parts Water, the particle size of each raw material component is 2-4 μm.

Embodiment 3

[0033] A kind of nitrile latex auxiliary material that white nitrile gloves are used comprises the raw material component of following parts by weight:

[0034] 22 parts of zinc oxide powder, 22 parts of sulfur powder, 5 parts of accelerator BZ powder, 6 parts of accelerator EZ powder, 5 parts of antioxidant KY-616 powder, 42 parts of titanium dioxide, 4 parts of dispersant NNO powder and 110 parts of Water, the particle size of each raw material component is 2-5 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com