Drive assembly

A technology for driving components and windings, which is applied in the direction of electric components, windings, and control/drive circuits, etc., and can solve the problems of large overall height changes and large tolerances of laminated stator cores.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

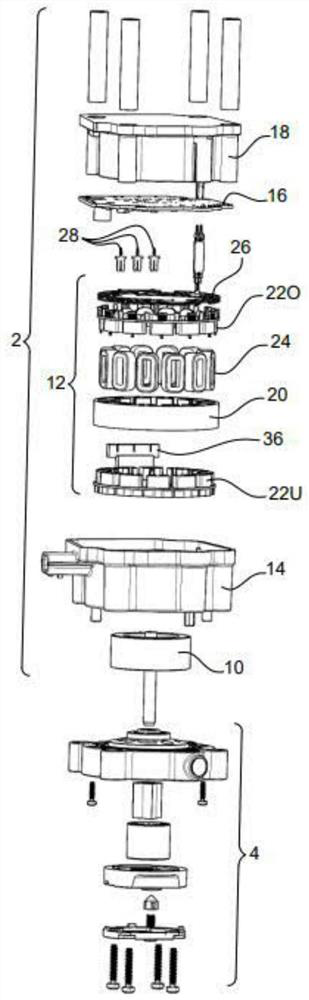

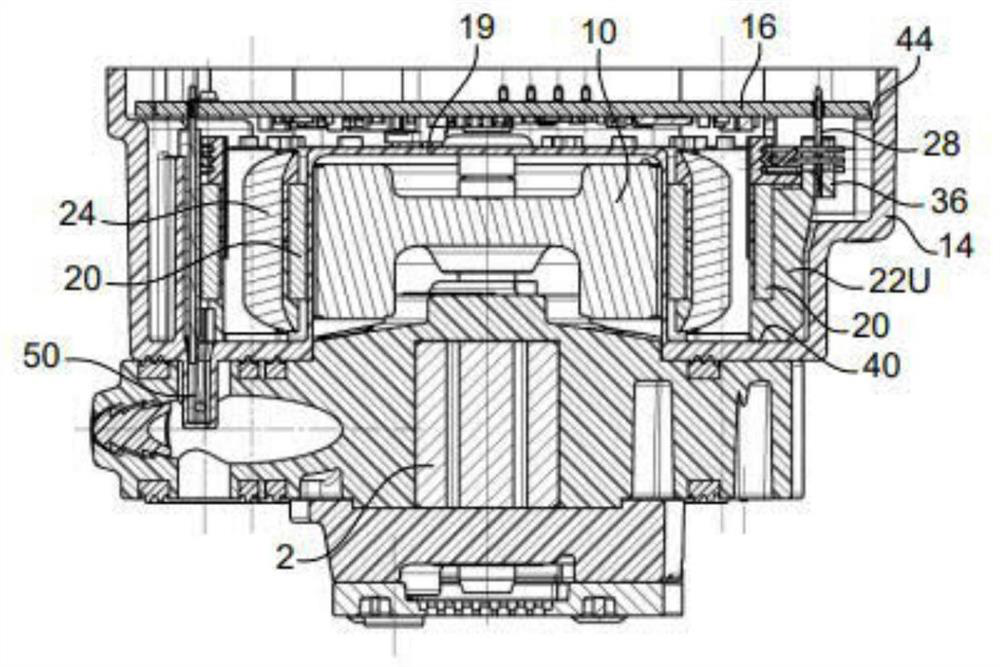

[0030] In perspective view, figure 1 A drive assembly with an electric motor 2 and an oil pump 4 is shown. The oil pump serves to provide a flow of hydraulic oil, whereby in particular the transmission actuators of the motor vehicle can be supplied. The electric motor 2 is used to drive the pump 4 .

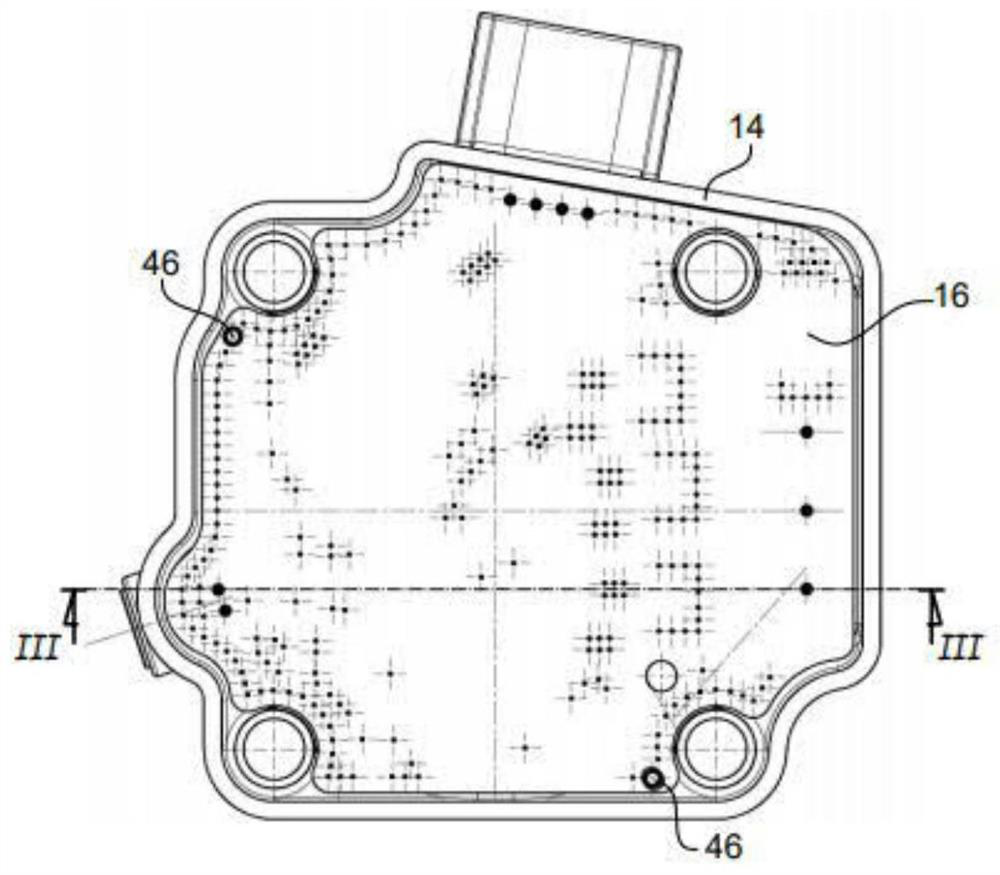

[0031] The electric motor 2 has a rotor 10 which is spatially arranged in a stator 12 . The stator 12 is arranged in a stator housing 14 which also houses a printed circuit board 16 . A housing cover 18 is also provided.

[0032] The stator housing 14 has a dome-shaped structure 19 such that although the rotor 10 is arranged inside the stator 12 it is still outside the stator housing 14 .

[0033] The stator housing 14 is preferably an injection molded part made of plastic.

[0034] The stator 12 has a core 20 consisting of stator laminations, which is assigned a stator insulation 22 formed from a lower part 22U and an upper part 22O. Furthermore, a winding 24 is provided f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com